5 tips to increase profits from cage-free egg production

Egg producers can address the additional costs and new challenges of moving hens into cage-free environments by focusing on these five factors.Author: Lesley Nernberg MSc, Regional Technical Services Manager Biomin

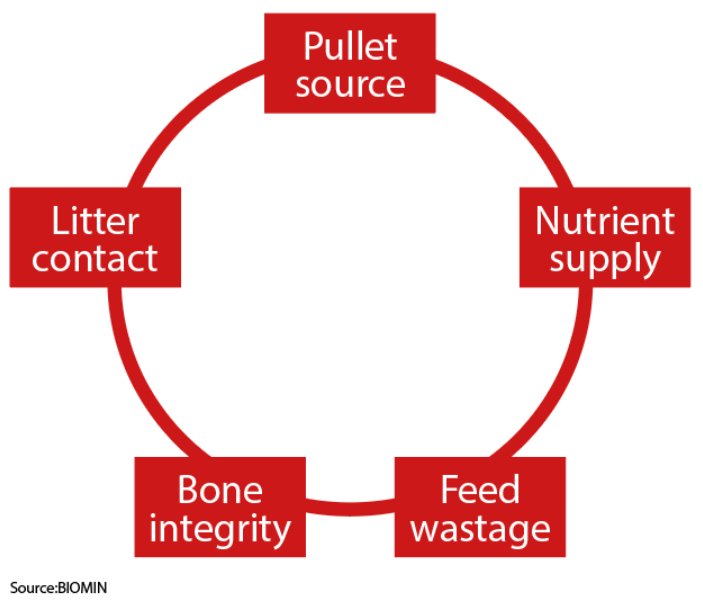

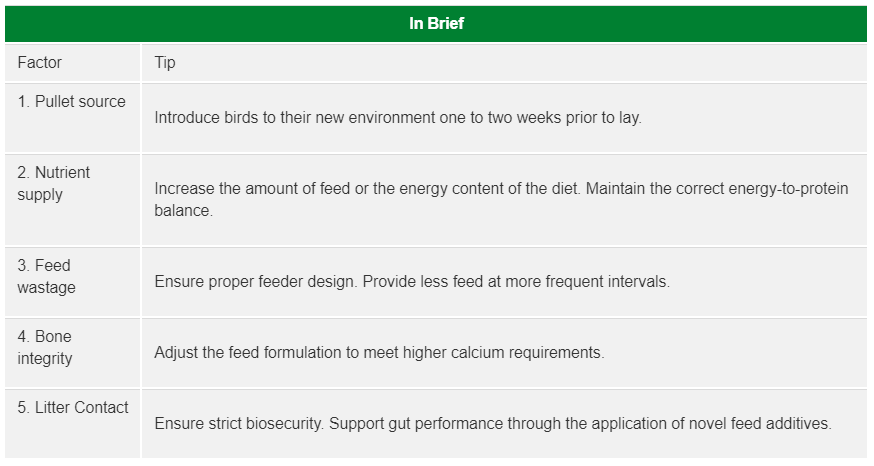

As birds in cage-free environments are more mobile versus those in conventional cages, their nutritional requirements are different. In addition, there is a need to alter the management, health, and nutritional strategies employed on the farm. The nutritional and health programs developed for conventional cage systems should be re-evaluated to account for the changes in bird welfare, health, and productivity associated with the cage-free environment. From experiences in North America and Europe, where cage-free systems have been widely adopted, egg producers should consider five factors (Figure 1) when converting to a cage-free housing system:

Figure 1. Five factors to consider when converting to cage-free housing

Pullet source

In general, pullets may be raised in conventional cages, floor-raised, or in specifically designed aviary pullet systems (Figure 2). It may be desirable to ease transition from the pullet farm to the egg production facility by raising pullets in a system that resembles their future layer-house system. Although birds raised in an aviary system are more expensive, they will be better adapted to the additional movement, freedom and space afforded in the cage-free system. In this case, pullets obtained from aviary pullet systems will be more productive and the least problematic.

Figure 2. Pullets in an aviary system ("Photo used with kind permission by Maarten Hagens. 2018, Bolegg Gallery, Vencomatic.ca, Iowa, USA.")

Tip #1. Introduce birds to their new environment one to two weeks prior to lay.

Birds should be moved to cage-free systems at least one to two weeks prior to the onset of lay, no later than 17 weeks of age. This will allow birds to become familiar with their new surroundings and to adapt to the nesting systems before start of lay.

Nutrient supply

The feeding of cage-free layers will differ from that of caged laying hens so the nutrient requirements and diets provided will need to be revised accordingly. The additional movement of the birds and higher competition for feed means that more energy is utilised on a daily basis. With this increased energy expenditure, birds may require up to 10% more energy depending on their current or base level. The additional energy may be provided either as an increase in the amount of feed, or as an increase of the metabolisable energy content of the diet. Maintaining the energy-to-protein balance (digestible amino acids) also needs to be addressed to ensure achievement of body weight targets and proper frame development.

Tip #2. Increase the amount of feed or the energy content of the diet. Maintain the correct energy-to-protein balance.

Feed wastage

When birds are removed from cages, competition for feed increases. Therefore, it is critical to have well-designed feeders to ensure feed wastage is limited. Less feed waste will help achieve more uniform body weights. It is important to provide an adequate number of feeders and the correct amount of feeder space so that all birds have free access to feed and a proper hierarchy can be established.

Flock uniformity may also be more difficult to control and manage in cage-free environments. Distributing feed across multiple locations in the barn will help to prevent overcrowding and will encourage subordinate hens to feed. Offering smaller meals at more frequent intervals may be a strategy to ensure adequate intake, resulting in the achievement of the desired uniform body weights, and reducing feed wastage.

Tip #3. Ensure proper feeder design. Provide less feed at more frequent intervals.

Bone integrity

Cage-free laying birds that are allowed to have increased movement put more strain on their skeletal system. Bone strength will need to be monitored and optimised under these systems. It is important to examine the nutritional factors influencing bone integrity such as the level, type, and source of minerals – especially calcium and phosphorus.

Since egg laying behaviour and activity is altered in a cage-free system, there may be an increased calcium demand to consider. Limestone, oyster shells, and other calcium, phosphorus, and vitamin D sources may need to be further supplemented so that enough calcium is absorbed and available during peak egg formation. The inclusion of an enhanced acidifier such as Biotronic® Top3 and a phytogenic feed additive such as Digestarom® in the diet may also enhance calcium absorption and bone integrity.

Tip #4. Adjust the feed formulation to meet higher calcium requirements.

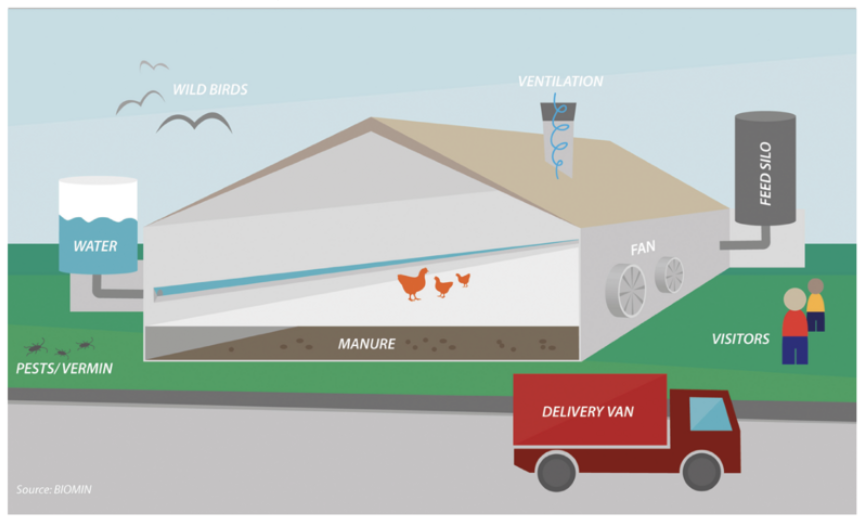

Figure 3. Potential sources of contamination on poultry farms

Litter contact

There are many sources of contamination on poultry farms as shown in Figure 3. In cage-free systems, diseases are more easily transmitted within a flock due to increased bird movement, bird-to-bird contact, and exposure to litter. Cage-free birds will face additional health challenges as a result of being exposed to higher pathogen loads within these litter-based systems. Gut health challenges such as coccidiosis and necrotic enteritis will become more evident along with other zoonotic pathogens such as E.coli and Salmonella, posing concerns to both animal and human health.

It is important to maintain strict biosecurity measures and keep the litter dry to lower the risk of disease and other health issues. Establishing and maintaining gut health is also critical for the maintenance of bird health and performance. A tailored strategy involving acidifiers, synbiotics (combined prebiotic/probiotic additives such as PoultryStar®), and phytogenics may help in this regard, and can be considered for incorporation to the feeding program.

Tip #5. Ensure strict biosecurity. Support gut performance through the application of novel feed additives.

Conclusion

By taking these five factors into consideration and applying these tips, you can ease the transition to cage-free housing and improve your likelihood of success. For further support, contact your local Biomin representative.