Cobb Breeding and Management Guide: Female feed management - from photo stimulation to peak production

Learn more about feeding and its influence on weekly mortality trendsEditor's note: This article is an excerpt from the Cobb Breeder Management Guide and additional articles will follow. The Guide was designed to highlight critical factors that are most likely to influence flock performance. To read or download the complete Guide or to view Cobb's other management guides, click here.

For any breeder flock, the period from the moment of photo stimulation to peak production is critical in terms of nutrition. After photo stimulation, the female will partition the available nutrients between maintenance, growth and the development of the reproductive system. A well-designed management program can influence how this partitioning takes place.

Female feed management from photo stimulation to onset of lay

From photo stimulation to onset of production, feed is allocated based on bodyweight. Birds that are photo stimulated with the correct body condition, usually require feed increases between 2 to 4 g/bird/week (0.44 to 0.88 lb/100 birds/week). If higher feed amounts are used, for example 4 or 5 g/week (0.88 to 1.10 lb/100 birds/week), consider increasing the feed amounts in 2 steps such as every 4 days with 3 and 2 g (0.66 and 0.44 lb/100 birds/week) increments.

Using conservative feeding programs from photo stimulation to onset of production will help reduce:

- The percentage of double yolks

- Low peak production issues

- Floor eggs, especially with community nest systems

- Egg peritonitis during the onset of peak production as well as spiking mortality due to prolapse, SDS, heart attacks, and fatty liver

- Overweight pullets because weight gain will be easier to control

- Production persistency related issues

Feeding and its influence on weekly mortality trends

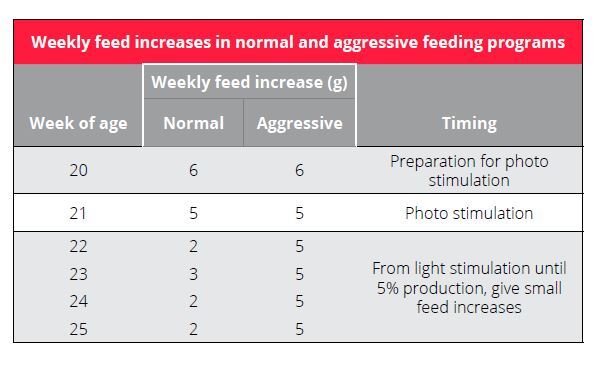

Weekly mortality comparisons for aggressive versus conservative feeding programs indicate, that after photo stimulation, higher weekly hen mortalities occur with aggressive feeding programs, similar to those used in the table below:

When the flock reaches 5 % daily production, a feeding program should be designed to lead production through peak. This program can be developed by deducting actual feed at 5 % of production from expected peak feed. Calculate the incremental increases for each 10 % increase in egg production. Feed hens for bodyweight until 5 % production is reached. Thereafter feed, increases should be adjusted according to daily egg production. Normally 40 % of the difference in total feed increase is given from 5 % until 45 % daily production and 60 % of the feed allocation between 45 and 80 % production. Peak feeds are given at varying daily production levels, from 70 % through > 80 %. It is important for each company to evaluate their daily production and bodyweight increases through peak to see if they are over feeding. Weekly mortality linked to egg peritonitis are a clear indicator of over stimulation.

Ensure quality feed ingredients in terms of energy and protein levels are being used for flocks going into peak production. Apply the latest Cobb recommended feed specifications to ensure that the females maximize their egg production. Birds going into peak are more susceptible to stress. Good quality ingredients are essential to give support to the birds, and for producing good quality chicks.

The hens should be capable of sustaining peak production on the 24 to 25 g of protein per day, 1000 to 1050 mg of digestible lysine and 950 mg of digestible methionine + cysteine. Large variations in house temperature will influence the amount of feed hens require. House temperatures should ideally be held between 21 °C (70 °F) and 22 °C (72 °F). Feed allowances may need to be adjusted to accommodate environmental conditions outside of this range.

Key points of female feed management (photo stimulation to onset of lay)

- An accurate and regularly calibrated feed weighing system is essential.

- Daily feed amounts must be calculated based on the actual bird number, not the number of birds initially housed. (Actual bird number= Birds initially housed – cumulative mortality and culling).

- Mash feed cleanup should be 2.5 to 3 hours for hens in peak production. Pellet or coarse crumble feed cleanup time should be 1.5 to 2 hours. Any sudden changes in cleanup time should be investigated immediately.

- It is strongly recommended to use the Cobb nutritional specifications that have been specifically formulated for the Cobb females and males.

- Breeder 2 feed containing higher levels of calcium and calories may be beneficial at around 35 to 40 weeks of age.

- Scratch feed may be beneficial to maintain fertility. It should be fed late in the afternoon at the maximum rate of 0.5 kg (1.1 lb) per 1000 birds, with this amount being included in the daily feed amount.

- Prevent feed wastage. Check for worn feeder troughs and spillage at the return to the feed hoppers.

- Maximum feed levels in the troughs should be set at 1/3rd full. Check slide gates daily for correct opening.

- The hopper inlet and outlet opening for the feed needs to be increased when using higher corners.

- Continue to run the feeding system until the entire day’s feed allowance has been distributed by the chain feeder.

- Feeding can be run automatically without people present, but the equipment needs to be well maintained. Old equipment requires staff to be present during feeding.

- Chain feeders with high corners prevent feed from spilling out of the trough and therefore, permit higher feed levels in the trough (see image above).

- The same procedures apply for pan feeders – generally pan feeder systems work better with pelleted and/or crumbled feeds. Fine mash feed will not normally work well with auger pan feeding systems.

- Silos should always be emptied between feed types and at least once a month during production to maintain good feed quality.

- Cobb does not recommend a pelleted feed during production phase due to very fast cleanup times, which may negatively affect feed distribution and performance, and increase nervous behavior causing scratches on thighs. Pelleted feed is only a good option under heat stress in peak production and/or with long feed cleanup times