Energy Saving Tips

Energy savings in turkey rearing can be made in nine key areas, explained Sanjay B. Shah of the University of North Carolina at the 2008 North Carolina Turkey Days.Abstract

Since confined turkey production is an energy intensive enterprise, high energy prices affect the profitability of turkey production. There are many things that turkey producers and integrators can do to reduce energy losses. The USDA Renewable Energy and Energy Efficiency Program can assist qualified producers with grants and loans to improve energy efficiency.

While there are many things that can be done to improve energy efficiency, the first one is to tighten the houses, so that leakages are minimized. Tightening the houses will help in both summer and winter.

Increasing insulation, where necessary can also reduce energy losses; one important area is converting curtain sides to solid sidewalls. Spray foam insulation offers a cost effective method to increase insulation levels.

The type of heater being used in the brooder houses can have a substantial impact on energy use. The newer quadradiant heaters may offer high efficiency and more uniform heating than other methods. Heater maintenance is also an important component of energy efficiency enhancement.

Selecting fans based on efficiency and not just airflow rate will help reduce electricity bills. Ventilation system maintenance such as tensioning belts and keeping shutters clean can contribute substantially to reducing electricity costs. Paddle fans or circulation fans in turkey brooder houses can reduce thermal stratification and hence, heat energy use. Attic ventilation offers the opportunity to use solar energy to heat the brooder houses and reduce heat energy use by about one-third. It can also improve litter and air qualities inside the house. However, attic ventilation requires good management.

Incandescent bulbs should be replaced with the newer dimmable compact fluorescent lamps or cold cathode bulbs that not only consume less power but also reduce labour costs.

Because of high propane and natural gas prices, there is considerable interest in heaters that use other fuels. Wood-fired heaters are cheaper to operate but are not as convenient or efficient as propane heaters. Heaters powered by reclaimed motor oil offer considerable potential in areas where it is readily available.

Finally, proper management and maintenance play important roles in reducing energy losses.

Introduction

Compared with the winter of 2007-2008, the Dept. of Energy has forecasted that the prices of propane and electricity in the South will increase by 10.3 and 7.7 per cent, respectively, during the winter of 2008-2009. Propane prices are probably more difficult to forecast than electricity prices because they depend on political, economic, and weather factors. While propane or natural gas is likely to be the bigger cost component in turkey brooding, electricity is more important in turkey grow-out. So, when you analyze turkey production as a whole, both propane and electrical costs are important. Hence, propane (or natural gas) and electricity are both important to the profitability of the turkey enterprise.

While the rising energy prices have affected bottom-lines of both the producers and integrators, there is help available. The USDA Renewable Energy and Energy Efficiency Program (REEEP) can provide up to 25 per cent grant support and up to 50 per cent guaranteed loans to qualified producers who want to improve energy efficiencies of their enterprises. Interested producers should be encouraged to contact their area specialized poultry agent or the author for advice and help. While there are many things that can be done to improve energy efficiency, the producer should take a hard look at his/her enterprise and focus on those things that make the most sense for their enterprise. Discussed below are some energy savings tips.

- Tighten the house

In the context of mechanically-ventilated houses, this means that you bring in fresh air only through planned inlets and expel exhaust air only through planned outlets or fans. In the vast majority of mechanically-ventilated turkey houses, during brooding or mild weather ventilation, fresh air is brought in through ceiling or sidewall inlets. During summer, when higher ventilation rates are needed, fresh air is brought in through cool cell pads or by dropping the curtains. As houses age, they lose their tightness, for example, as the lumber shrinks and warps, cracks develop and instead of fresh air entering through the house only through the inlets, a portion of the air comes in through the cracks.

A good test of your house tightness is to latch shut all inlets and openings, turn on one 48-inch fan (or two 36-inch fans), and watch your pressure sensor. While a reasonably tight older house may give 0.15 inches of static pressure, a new house with solid side walls may read as high as 0.33 inches. Obviously, a less tight house may read only 0.03 – 0.04 inches, indicating that a large portion of the fresh air is coming in through cracks. While many cracks can be located with the naked eye, smoke can be used to not only identify small cracks but also to visualize airflow. While my experience has been limited to ‘smoke bombs’ and larger, though portable smoke or fog machines, places such as Party City sell ‘fog machines’ for much less than $100. Once these cracks are identified, they should be sealed with caulk, foam or weather-stripping. Substantial air leaks can occur through the sides of curtains and installing curtain flaps and boots can minimize these leaks. Tunnel inlets should be tight and insulated. Back-drafting through fan shutters (that are not in use) also cause large air leaks; consider covering shutters not in use with foam boards or fan covers. Tightening the house not only reduces heating cost during winter and brooding but it also improves ventilation effectiveness during summer. Payback on time and money spent on tightening the house is very rapid.

Simpson and Donald (2005) reported on two identical 25-yr broiler houses (40 feet × 400 feet) in Alabama. One house was tightened by spraying foam to the sidewalls, end walls, and ridge vents; curtain flaps and boots were installed, doors were weather-stripped and unused openings were sealed. The pressure on the ‘tightened’ house increased from 0.03 inches to 0.16 inches. Heating costs on the tightened house were reduced by 30 per cent and during summer, the fan end ran 3-4°F cooler during summer and better settlements were obtained for every flock. Worley et al. (2005) estimated that tightening poultry houses could reduce heat energy use by 15 per cent. There is no doubt in my mind that this is the first step the producer should take to reduce energy use.

- Increase insulation when necessary

The level of insulation required for an animal barn depends on its location (hence, climate), animal factors (species, stage, and density), and economics. The Midwest Plan Service divides the continental US into three climatic zones and the recommended level of ceiling and wall insulation in each of these three zones depends on whether a barn is ‘cold’, ‘modified environment’, or ‘supplementally heated’ (ASABE, 2008). The highest level of insulation (wall and ceiling) is required in the supplementally heated structures, followed by the modified environment structures, and then the cold structures.

Except for the southeast corner, the rest of North Carolina falls in zone 2. Per the recommendation of the Midwest Plan Service (ASABE, 2008), ‘supplementally heated structures’, such as turkey brooder houses in North Carolina (zone 2) should have insulation values of R-14 for sidewalls and endwalls and R-25 for ceilings. The insulation values for the walls and ceilings of turkey grow-out houses would be R-6 and R-17, respectively, though the current practice for both walls and ceiling ranges from R-7 to R-9 (ASABE, 2008). While these differences in R values can be confusing, the grower, in consultation with the integrator (and with help from Cooperative Extension) needs to make a decision for his/her conditions.

Based on energy use, increasing insulation will provide more returns in brooder houses than grow-out house though if you consider the summer of 2007, providing adequate insulation in the grow-out houses is also a wise choice. New solid sidewall turkey brooder houses should definitely use R-14 for the walls and R-25 for the ceiling because of the high price of propane. Heat loss or gain can be calculated using the following equation.

In equation 1, heat lost or gain is expressed in Btu/hr, surface area could be the area of the heat transfer surface in square feet, temperature difference is the difference between the inside and outside temperatures, and R-value is the value of insulation. If the ceiling area is 20,000 ft2, the inside target temperature is 90 F and the outside air temperature is 45 F, and the ceiling insulation has a value of R-19, the heat loss is calculated below.

If the insulation in the ceiling was R-25, for the above situation, heat loss would have been reduced to 36,000 Btu/hr. Over a 24-hr period, the R-25 ceiling would have saved 272,832 Btu or nearly 3 gallons of propane (propane has a heat value of about 92,000 Btu/gallon).

Insulating structurally sound open ceiling houses (brooder and grow-out) is a no-brainer. The question is what to do with under-insulated houses? The simple answer is to look at the economics on a house to house basis. For curtain-sided houses, insulating both sidewalls would be cost effective, provided there is generator. If cost is an issue, at least the north sidewall that receives the most summer sun and the least winter sun should be insulated. Un-insulated endwalls should also be insulated. Say, you have a 41 feet wide and 500 ft long turkey grow-out house with 400 ft of curtain 4 feet high. If the ambient temperature is 90°F and the target temperature inside is 70°F, the curtain (R-1) will allow a heat gain of 64,000 Btu/hour from both sides. Say, if you have a ‘low-cost’ (described below) insulated sidewall (R-8), the heat gain is reduced to 8,000 Btu/hr. The reduction in heat load is equivalent to two pancake brooders running full-time inside the house during summer with large birds. Can we afford to not insulate the sidewalls? Worley et al. (2005) estimated that, on average, solid sidewalls would reduce heat energy use by 15 per cent.

Of course, there are routine maintenance issues relative to insulation that should be addressed as soon as they are detected. Darkling beetles attack many types of insulation. In houses with drop ceilings and tunnel ventilation, the high air speed and vibrations cause the insulation at the ridge to slide, resulting in undesirable heat losses in winter and heat gain in summer (Figure 1). Further, over time, loose fill insulation (particularly, cellulose) will settle (and pack), or become wet, reducing R-value.

Increasing insulation has become easier than before because of spray foam insulation. Spray foam insulation can be applied directly over the curtain and chicken mesh wire on the sidewalls (Figure 2), thus creating a low-cost solid sidewall house. Closed cell foam (2 lb/ft2 per inch of thickness) insulation provides R-6 to R-7 per inch and costs $1/ft2 for one inch thickness (Ed Githens, personal communication, 14 May 2008). Open cell foam (0.5 lb/ft2 per inch of thickness) insulation provides about R-3.5 to R-3.75 per inch and costs $0.30/ft2 per inch of application. While the open cell foam provides more than half the insulation value at less than one-third the price of the closed cell foam, the open cell foam insulation is easily damaged by darkling beetles. Other advantages of closed cell foam include reduced vapor passage and moisture absorption compared with open cell foam. Hence, while material cost and R value are important considerations in selecting a proper insulation material, other factors should also be considered.

- Heater selection and maintenance

This tip focuses on the use of propane or natural gas heaters. The issue of changing fuel type to save money is discussed separately. One important consideration in brooder selection is the fraction of heat output in the radiant form. Radiant energy can travel through still air (or vacuum) and heat up objects such as litter or poults on the floor. In brooding, it is crucial to heat the floor and poults and not the air.

Depending on the mechanism of heat transfer and the design of the heating system, there can be substantial difference in energy use among brooders. A forced air furnace heats the air in the house through convection and is the least preferred method for brooding. The pancake or jet brooder transfers 40 per cent of its energy as radiant heat to the floor and 60 per cent to the air as convective heat (Fairchild, 2005). While not as effective as the radiant brooder, this type of brooder is still widely used in the US, particularly for turkey brooding. Because of its design, the radiant brooder transfers 90 per cent heat to the floor (Fairchild, 2005). Radiant brooders have 15-30 per cent lower fuel consumption than the pancake brooders (Lacy, 2002). While the pancake brooder, located about 3 feet above the floor, heats the floor beneath it more-or-less uniformly, the radiant brooder, located about 4-5 feet above the floor creates concentric zones of temperature, with the hottest area in the center. Hence, radiant brooders have larger coverage and offer more flexibility of thermal comfort for the chicks.

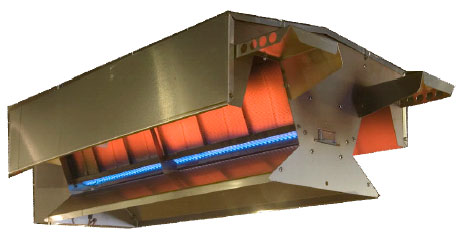

In a radiant tube heater (Figure 3), very hot air from a burner is forced through a metal pipe causing the pipe to heat up (up to 1000°F). The outer surface of the pipe then radiates the heat to solid objects, primarily the floor. Heat reflected upward, is deflected downward by reflectors. Radiant tube heaters can preheat poultry houses much faster than radiant brooders, saving energy (Czarick, 2005); a radiant tube heater may heat the poultry house to 90°F in 4 hours versus 48 hours with a radiant brooder. It also spreads more of the warmth to the sidewalls and reduces the hot spot directly beneath the brooder (Donald et al., 2003). Having fewer heaters (versus radiant brooders) also reduces maintenance. Being located much higher above the floor than radiant brooders, the tube heaters do not have to be raised or lowered. However, in drop ceiling houses, manufacturer's instructions on shielding and clearances should be strictly followed to protect the vapor barrier, electrical wires, and fogger lines from melting or damage. Lowering the height of the radiant tube heater will reduce the likelihood of damage to the ceiling but the width of the house floor that will be heated will be reduced, with higher temperatures directly beneath the heater. Please read the article by Czarick (2005) for more on radiant tube heaters.

The quadradiant or quad heater (Figure 4) is a relatively new entrant in the poultry market. Unlike the radiant or jet brooders that produce circular heating patterns, the quad heater produces a rectangular heating pattern, thus minimizing cold spots in a rectangular house. It has a reflector at the bottom that reduces excessive heating directly below the unit. Agile Manufacturing, the manufacturer of Shenandoah heaters and brooders, claims that compared with other heaters, the quad heater minimizes cold and excessive hot spots. Mike Czarick (University of Georgia) is also of the opinion that the quad heater gives the most uniform heat distribution of all heaters. Unlike the tube heater, no air intakes, ducting, or pressurized burners are required. Compared with radiant brooders or many more jet brooders, fewer quad heaters are required. However, compared with tube heaters, slightly more quad heaters are required. Like tube heaters, caution must be exercised in installing quad heaters so that the drop ceiling, electrical wires and water lines are not damaged. Care must be taken to prevent direct air movement on the quad heater because it will reduce the proportion of heat available for radiant heating; this may present some challenges with managing the inlets because these heaters are installed about 9 feet above the floor.

While studies comparing the economics of using radiant brooders versus tube heaters or quad heaters are not available, tube heaters offer a clear economic advantage vs. pancake brooders and forced air furnaces due to reduced energy use. Fewer tube (or quad) heaters versus brooders will reduce maintenance costs. Turkey brooder operations that currently considering replacing pancake brooders should consider tube or quad heaters to reduce energy use and maintenance needs versus switching to radiant brooders that have higher maintenance needs than the tube or quad heaters. However, when considering upgrading the heaters, the producer should tighten his/her house and increasing insulation where necessary.

Heater maintenance is crucial to optimizing performance and should be considered a profit center, not a cost center. Manufacturers’ guidelines on scheduled maintenance should be followed diligently. Some general recommendations are given below.

- Use compressed air for cleaning emitters, canopy and reflectors.

- Orifices should be cleaned only with the proper size of orifice drill

- Make sure that your thermostat is reading the temperature accurately. An accurate hand-held thermometer is a good reference to check thermostats.

- Ventilation system

A well-designed ventilation system brings in the required amount of fresh air through the planned inlets and exhausts the desired amount of stale air. When heaters are in use, the fresh air is mixed with the rising warm air so that some of the heat is transferred down to the birds. Hence, the ventilation system not only helps maintain comfortable (and uniform) temperature and humidity regimes inside the house but also proper air quality. The objective of summer ventilation is to reduce heat buildup inside the house. Winter ventilation removes moisture and helps maintain healthy oxygen levels inside the house. It is generally assumed that winter ventilation also allows maintenance of acceptable levels of noxious gases (e.g., ammonia and carbon dioxide) in the house. However, when poultry houses are not cleaned out often enough, there can be substantial build up of litter, and hence ammonia. In this situation, additional steps may be required to maintain acceptable air quality. Mild weather ventilation is the combination of summer and winter ventilation.

The design of a proper ventilation system starts with the selection of an appropriate fan. In selecting fans, it is important to consider the airflow rate (cfm) at the design static pressure as well as the fan efficiency (cfm/Watt). Worley et al. (2005) estimated that high efficiency fans could reduce electricity use by 15 per cent in poultry houses. In negative ventilation systems in poultry houses, during winter or mild weather, the inside of the house is at a static pressure of 0.1 to 0.12 inches of water column below atmospheric pressure. During summer, in tunnel ventilated houses (when air is moved along the length of the house from one end to the other), the negative static pressure may be 0.08 inches or lower. Therefore, a fan should be selected based on its airflow rate at the static pressure at which it will operate and not at zero static pressure. It is prudent to select a fan based on its airflow rate at 0.12 inches since dust build-up (more on this later) will also increase static pressure and reduce airflow rate. As is clear from Figure 5, while fan A has higher airflow rate at 0 inches static pressure than fan B, fan B has higher airflow rate at 0.125 inches. Further, fan B has greater efficiency in the entire range of static pressures tested indicating that watt for watt, fan B can move more air than fan A.

Growers also need to consider whether a high capacity fan will save them money over a standard fan (Czarick, 2007). While the high capacity fan moves more air, it may have lower fan efficiency (cfm/Watt) than the standard fan. Czarick (2007) reports that the annual operating cost of a standard fan is lower than that of the high capacity fan based on 12 standard and 11 high capacity fans in a tunnel house. The take-home message is that if a number of fans meet your airflow rate needs at the static pressure expected, you should pick the one with the highest fan efficiency, provided all other factors are the same.

Aspect of fan maintenance has to do with the fan belt. The fan belt should not be worn and be in proper tension. Worn belts ride lower in their pulleys and also slip more (because they become glazed); this could result in reduction of airflow rate of 5 to 10 per cent, even when the belt seems to be in proper tension. Loose (and worn) belts can reduce airflow rates by up to 60 per cent (Janni et al., 2005). Reduced ventilation could affect bird performance. Growers are conscientious about tensioning their fan belts between flocks, but belt-tensioning is time-consuming. A self-tensioning system for belt that uses a combination of the motor weight and spring action will save energy, money, and time. If a retrofit self-tensioning kit is unavailable, an adjustable tensioner (that would have to be adjusted periodically) would still be a reasonable compromise. However, even with the tensioner, belts need to be replaced on a regular basis. Twist-lock or link belts are very popular with poultry growers because they are relatively inexpensive and can be adjusted easily by adding or removing a link; however, they also need to be Twist-lock or link belts are very popular with poultry growers because they are relatively inexpensive and can be adjusted easily by adding or removing a link; however, they also need to be tightened regularly.

It is also important to make sure that the V-pulleys are properly aligned with one another, otherwise, belt wear will be high and airflow rate will be reduced. Only sealed bearings that are lubricated for life should be used in ventilation fans. Growers may select bearings that require periodic lubrication because of lower prices; however, when lubrication schedules are not followed, bearings and even fan motors can be damaged.

Dust accumulation on fan shutters and guards can also reduce airflow rates and increase energy use. Donald (200x) reported that a 36-inch fan at 0.05 inches of static pressure with clean shutters had an airflow rate of 8,519 cfm compared with 6,617 cfm with dirty shutter. Hence, it is important to keep shutters and guards clean; this also applies to the air inlets as dirty air inlets will reduce airflow and increase fan runtimes.

Another aspect of ventilation that can affect energy use is operation of the inlets that bring in fresh air during cold and mild weather ventilation. Latch shut all inlets within 8 feet of the fans as air drawn through these inlets will immediately be exhausted by the fans and thus, not be available for ventilation. The opening width of the inlets have to be matched with the static pressure in the house (depends on the number of fans in operation) as well as the number of unlatched inlets. For this, it is important to consult the airflow capacity of the inlets at different opening widths and static pressures. In cold weather, the opening width of the inlets should be such that fresh air is pulled in at speeds of 800 to 1,000 ft/min across the ceiling so that it can mix thoroughly with the rising warm stale air and transfer some of the heat to the birds below. If the inlets are open too wide, cold air will sink to the ground below and chill the birds while inlets that are too narrow in width can choke the fans. In mild weather and with older birds, the inlets should open wide enough to direct fresh air down to the birds.

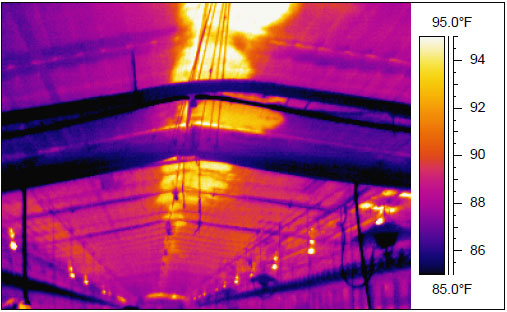

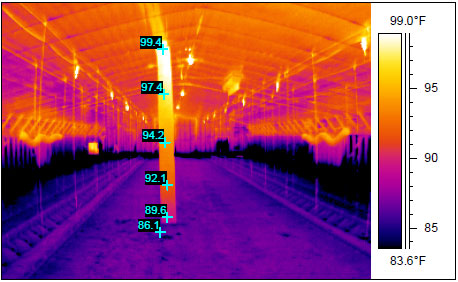

- Using mixing or paddle fans

During brooding and heating in winter, warm air rises to the ceiling. While some of that warm air is brought down to bird level by using ceiling and sidewall ventilation, a lot of that heat can be lost through conduction and convection through the ceiling. This phenomenon, known as temperature (or thermal) stratification can commonly result in temperature differences of 15-20°F between the floor and the ceiling (Figure 6). Thermal stratification is greater in open ceiling houses (i.e., with no ceiling insulation) versus drop ceiling houses. Forced air furnaces will cause the greatest stratification followed by pancake brooder. However, even with radiant brooders, in an open ceiling house, I have observed temperature difference of 5-6°F.

Fans can be used in poultry houses to break the thermal stratification and reduce energy loss. Axial fans can be mounted beneath the ceiling along the length of the poultry house to move some of the warm air down to bird level. Czarick and Lacy (2000) reported that by better mixing the air in the house using two 18-inch direct drive circulation fans in the brood chamber, the floor temperature was increased by 5°F while propane cost was reduced by 30 per cent in a house with forced air furnace. Flood et al. (1998) reported that using ceiling fans in the downdraft mode in the brood chambers resulted in reduced total energy use by 8 per cent. However, in the downdraft mode, the ceiling fans should be used at reduced speeds to ensure that airspeed at bird height does not exceed 50 ft/min to prevent the poults from getting chilled. Using ceiling fans in the updraft mode can ensure good thermal mixing and reduce energy use in brooding. In turkey brooder houses, ceiling fans (56/60 inches) are usually installed at the highest point at 50-ft spacing. While more expensive, agricultural fans designed to better resist dust, spray, and moisture are preferred to fans designed for home use. Worley et al. (2005) estimated that circulation fans could reduce heat energy use by 20 per cent though actual reductions would depend on type of heater and whether the house was open ceiling or drop ceiling.

- Attic ventilation

The metal roofs on poultry houses act as large solar collectors that heat up the air in the attic. Drawing fresh, tempered air through the attic rather than through the sidewall or ceiling inlets can result in reduced energy use to heat the house during brooder and winter. While attic ventilation is widely used in the colder regions of the US, it has been getting a lot of interest in the southeastern US in the past couple of years due to high fuel prices. Purswell and Lott (2007) reduced propane use by 24 per cent using attic ventilation (vs. sidewall ventilation) in spring broiler flock in Mississippi. Air inside the attic ventilated house was drier which could improve air quality by reducing ammonia formation (Purswell and Lott, 2007). Campbell et al. (2008) reported that in Alabama, two new broiler houses with attic inlets had 17 per cent lower gas consumption than two identical houses that had sidewall inlets. Litter was drier and humidity was lower in the attic ventilated houses (Campbell et al., 2008). During mild weather, the attic ventilated houses consumed 35 per cent less propane (Campbell et al., 2008).

While the research thus far has been on broiler houses, it seems that using attic ventilation in turkey brooder houses will also result in substantial gas savings and improve air quality and litter conditions. Because brooding temperatures are slightly higher for turkey poults than broiler chicks, the savings may be even higher. Campbell et al. (2008) reported that installing attic vents on a 40 feet × 500 feet broiler house was $3,600 which would be about the same for a 50 feet × 400 feet turkey brooder house. The attic vents should be designed for the airflow rates of the minimum ventilation fans. For example, if the required minimum ventilation rate is 4,000 cfm (including extra ventilation for the brooders in operation) and this is achieved by running two 36 inch fans (total 20,000 cfm) for 1 minute out of 5 minutes, your attic vents should be able to move the 20,000 cfm. Since attic heat is free, running the minimum ventilation fans longer will give you drier litter (and better house conditions) which will more than offset the increased cost of electricity to run the fans longer (Campbell et al., 2008). Modern environmental controllers can provide separate controls for the sidewall (or ceiling) and attic inlets. If mild weather ventilation is required, the attic inlets can be shut off and the sidewall or ceiling inlets opened.

However, attic inlets require management. A house should be tightened to a static pressure of at least 0.1 inch before installing attic inlets (Campbell et al., 2008). Warm, moist air from the house should never be allowed into the attic, otherwise, there will be corrosion and insulation will become wet and lose its R-value. During lay-outs, it is important to ensure that the attic does not get cold. This will cause condensation which can result in corrosion and degradation of the insulation. So, running minimum ventilation fans on timer should be considered during lay-outs.

- Replacing incandescent bulbs

Incandescent bulbs, though cheap, are wasteful because they use only a fraction of the energy they consume for lighting, the rest of it being lost as heat. Compact fluorescent lamps (CFLs) require two-thirds less power and last ten times longer than the incandescent bulbs. However, unlike the incandescent bulbs, the older CFL required a specialized dimmer. However, the newer dimmable compact fluorescent lamps (CFLs) have solved that problem. Based on energy savings as well as reduced labour to replace burnt-out lamps, a recent analysis on replacement of incandescent bulbs with dimmable CFLs indicated that payback period was under one year.

My cooperating broiler producer uses dimmable cold cathode bulbs and he is satisfied with them. These bulbs consume 20 per cent of the energy of incandescent bulbs and last 18,000 to 25,000 hours whereas the incandescent bulbs last about 1,000 hr. Farmtek sells 5-watt dimmable cold cathode bulbs for $6.95 each with substantial volume discounts. Ag Supply (910-652-4706) in Ellerbe sells 8-watt dimmable cold cathode bulbs for $9 each. (no volume discount). There are numerous other sources on the Internet that sell both dimmable CFLs and cold cathode bulbs. These bulbs will provide rapid payback.

In Delaware, where electricity rates are very high, some broiler producers are using LED (light emitting diode) lights (Van Wicklen, 2005). These lights consume 35-40 times less power than incandescent bulbs and can have useful lives exceeding 100,000 hours. The LED lights are dimmable and very rugged. However, these bulbs are expensive, retailing for $12 each (for a 0.7- watt bulb, equivalent to a 25-30 watt bulb). Consult Van Wicklen (2005) for details on use of LED lighting.

- Replacing propane or natural gas heaters with other fuel sources

Because of the high price of propane and natural gas, there is a lot of interest in heaters that use other fuels. While corn-fired heaters are no longer economically feasible because of the high price of corn, many of these heaters can burn wood pellets that are uniform in size and high quality (Drewry et al., 2008). The University of Arkansas is evaluating wood pellet heaters in poultry houses. Burning raw litter (at the farm level) has been shown to be neither technically feasible nor user friendly (Drewry et al., 2008). There are also large heaters that burn wood chips like Messersmith Manufacturing of Michigan that builds industrial size heaters (1,000,000 to 20,000,000 Btu/hr). Using heaters that burn #5 heating oil (reclaimed motor oil) holds promise, where it is available.

If you compare the cost of different fuel sources for one million Btu (MMBtu), after taking into account the efficiencies of the different systems, propane is 9 times more expensive than wood chips and twice as expensive as wood pellets. (Propane heaters have 98 per cent efficiency compared with 70 per cent for wood pellet heaters.) The most efficient wood-fired systems heat water and the hot water is circulated through a network of pipes inside the house. While one such system may be large enough to supply two or more houses, a pipe/duct system is needed to move heat energy from the heater to the houses. Smaller units can also be located inside the house but they will take up floor space and will require modifications to the house.

The reason why it is difficult to suggest a ‘biomass-type’ alternative to propane- or natural gas-fired heaters is the lack of controlled studies in poultry houses though some studies are in progress. In a study on greenhouse heating, Fasina et al. (2006) showed that compared with natural gas, biofuel pellets (switchgrass, peanut hulls or poultry litter) reduced energy use by up to 35 per cent. Switchgrass and peanut pellets performed better than poultry litter (Fasina et al., 2006).

Donald et al. (2005) compared energy use in two tight broiler houses in Alabama, one with only radiant brooder and forced air furnaces using propane and the other house also had a 500,000 Btu/hr oil-fired heater. In the house with the oil-fired heater, the warm air was distributed through a collapsible duct with holes. Over five flocks, the house with the oil fired heater not only reduced the total energy used but also substantially improved bird performance (Simpson et al., 2005). Even in older houses, the oil-fired heater substantially reduced energy use (Simpson et al., 2005). Hence, if there is a reliable supply of reclaimed motor oil, oil-fired heater could hold a lot of promise.

- Routine management and maintenance

Routine management and maintenance can make small differences in many places and these all add up. Hence, management and maintenance should be viewed as profit centers, not cost centers. An example of management might be to set your environmental controller on a 5 minute cycle instead a 10-minute cycle; this will result in a more uniform thermal environment during brooding. Preventing water leaks is another important aspect of management that may not receive much attention. With leaky waterers, during brooding, part of the heat which would have otherwise gone to warm the poults will be used to vaporize water. (At 77°F, you use up 1,025 Btu of heat to evaporate 1 pound of liquid water.) Additionally, this evaporated water increases the humidity in the house, degrading air quality. Use of acidifiers may not provide as much benefit in reducing energy use in turkey production as in broiler production where chicks are brooded on built-up litter. However, acidifiers in turkey grow-out houses may improve bird performance by reducing ammonia levels.

References

ASABE Standards. 2008. ANSI/ASAE S401.2 FEB1992 (R2008): Guidelines for Use of Thermal Insulation in Agricultural Buildings. St. Joseph, MI: ASABE.

BESS Laboratory. 2008. Agricultural ventilation fans: Performance and efficiencies. Urbana- Champaign, Ill.: University of Illinois, Bioenvironmental and Structural Systems Laboratory. Available at: www.bess.uiuc.edu/. Accessed 4 September 2008.

Campbell, J., J. Purswell, G. Simpson and J. Donald. 2008. Actuated attic inlets – a progress report. National Poultry Technology Center, Auburn Univ.

Czarick, M. 2005. Radiant tube heater floor heating patterns. Poultry Housing Tips 17(5). Cooperative Extension Service, Univ. of Georgia, Athens, GA.

Czarick, M. 2007. High capacity tunnel fans decrease producer profits! Poultry Housing Tips 19(12). Cooperative Extension Service, Univ. of Georgia, Athens, GA.

Czarick, M. and M. Lacy. 2000. Reducing temperature stratification in houses with forced air furnaces. Poultry Housing Tips 12(4). Cooperative Extension Service, Univ. of Georgia, Athens, GA.

Donald, J. 200x. Value of clean shutters proven in laboratory test. Fact sheet. Alabama Cooperative Extension Service, Auburn Univ.

Donald, J., M. Eckman and G. Simpson. 2003. Radiant tube heating - questions and answers. The Alabama Poultry Engineering and Economics Newsletter No. 26 (Nov.). Alabama Cooperative Extension Service, Auburn Univ.

Drewry, R., J. Wimberly and T. Costello. 2008. Poultry farm energy audits and alternative energy sources. Arlington, VA: Pellet Fuels Heat Institute.

Fasina, O.O., D. Bransby, J. Sibley and C. Gilliam. 2006. Heating of greenhouse with biofuel pellets. ASABE Paper No. 064183. St. Joseph, MI: ASABE.

Flood, C.A., J.L. Koon, R.D. Turnbull and R.N. Brewer. 1998. Energy savings with ceiling fans in broiler houses. Appl. Eng. Agric. 14(3):305-09.

Janni, K.A., L.D. Jacobson, R.E. Nicolai, B. Hetchler and V.J. Johnson. Airflow reduction of large belt-driven exhaust ventilation fans with shutters and loose belts. In Livestock Environment VII, Proc. of VII International Symposium. Publication No. 701P0205. St. Joseph, MI: ASAE.

Lacy, M. 2002. Broiler management. In Commercial Chicken Meat and Egg Production, 5th ed., editors D.B. Bell and W.D. Weaver, Jr. Kluwer Academic Publishers.

Purswell, J.L. and B.D. Lott. 2007. Heating poultry houses with an attic ventilation system. ASABE Paper No. 074125. St. Joseph, MI: ASABE.

Simpson, G. and J. Donald. 2005. Energy solutions for poultry producers. Alabama Agricultural Energy Conference.

Simpson, G., J. Donald, D. Bransby and J. Campbell. 2005. Oil-fired heating shows costcutting potential. The Poultry Engineering, Economics and Management Newsletter No. 33 (Jan.). Alabama Cooperative Extension Service, Auburn Univ.

Van Wicklen, G. 2005. Using LED lights can reduce your electric costs. Applied Poultry Engineering News Vol. 3(1). Cooperative Extension Service, Univ. of Delaware.

Worley, J.W., M. Czarick and B. Fairchild. 2005. Trends in US Poultry Housing for Energy Conservation. In Agriculture as a Producer and Consumer of Energy edited by J. Outlaw, K. Collins, and J. Duffield. Tall Gables, UK: CPL Press.

Further Reading

| - | You can view other presentations from the 2008 North Carolina Turkey Industry Days by clicking here. |