Broiler Care Practices

By Ralph Ernst, Duncan McMartin, Francine Bradley, Donald Bell, James Millam and edited by Carolyn Stull - "Broiler Care Practices" is one of a series of University of California publications addressing the issue of animal care as it relates to food production in California. The information was contributed jointly by the Poultry Workgroup, Cooperative Extension and industry representatives.| The authors include: Ralph Ernst, Poultry Specialist, Department of Avian Sciences; Duncan McMartin, Extension Veterinarian, Emeritus, School of Veterinary Medicine; Francine Bradley, Poultry Specialist, Department of Avian Sciences; Donald Bell, Poultry Specialist, Department of Avian Sciences; James Millam, Associate Professor, Department of Avian Sciences. |

Contents

- INTRODUCTION

- HATCHING AND SERVICING CHICKS

- Incubation

- Chick Processing

- Beak Trimming

- Hatchery Vaccination

- Hatchery Losses

- BROODING AND GROWING

- Brooding Temperature

- Litter

- Light for Brooding

- Chick Guards

- Feeding and Watering Procedures

- Space

- CARE OF JUVENILE AND ADULT BREEDING STOCK

- Feeding

- Nests

- Lighting

- Egg Care, Handling, Sanitation and Storage

- ENVIRONMENT

- Housing

- Air Quality

- Ventilation

- HEALTH MAINTENANCE PROGRAMS

- Immunization

- Development of Immunization Programs

- Cleaning and Disinfecting Houses and Equipment

- Preventive Medication

- Farm Security

- Monitoring Mortality

- Dead Bird Disposal

- MINIMIZING NUISANCE ASPECTS OF FARMS

- Air Quality

- Manure Management and Odor Control

- Fly Control

- Landscaping

- BIRD HANDLING AND TRANSPORTATION

- Catching

- Loading

- Vehicles

- Transportation Conditions and Route

- PROCESSING

- Unloading

- Shackling

- Stunning

- Slaughter

- BIBLIOGRAPHY

- GLOSSARY

INTRODUCTION

Animal care recommendations have evolved from years of scientific research and practical experience. This publication was designed to outline acceptable practices for the care and rearing of meat-type chickens (rock-cornish game hens, broilers, fryers, or roasters) and breeding stock.

Poultry meat production is an important industry in California. In 1996, California produced 234 million meat chickens valued at $457 million. The majority of these meat chickens were grown on an estimated 175 ranches in the San Joaquin Valley. In addition, there are many smaller farms in California producing specialty chickens.

Poultry require constant care and attention. This care should be performed or supervised by an experienced person. Novices who wish to raise poultry should familiarize themselves with detailed information on proper care before chicks are obtained. Help and information is available from the University of California, Cooperative Extension, experienced industry representatives, and through many books and publications.

HATCHING AND SERVICING CHICKS

Incubation

Proper incubation conditions are necessary to produce healthy chicks. Optimum conditions vary with the age, shell quality and size of eggs to be set. Dry bulb temperature in forced draft

incubators, should be between 99.5 and 100°F (37.5 - 37.8°C) with a wet bulb temperature of 83 to 87°F (28.3 - 30.5°C). Eggs should be set large end up and turned hourly, or more often,

during the first 14 days of incubation but never after 18 days of incubation. Hatchers, hatching trays and other equipment should be cleaned and sanitized after each use. Nest clean eggs are preferred. They may be sanitized on the farm or at the hatchery using approved procedures. Egg sanitation is more effective if it is done as eggs are collected or immediately after collection. Setter and hatcher rooms require proper ventilation (approximately one air exchange per minute) to provide oxygen and remove carbon dioxide produced by developing embryos. Most commercial setters perform best when the room temperature is maintained at about 78°F (25.6°C) with a relative humidity of 50 to 55 percent.

Chick Processing

Chicks should always be transported in new disposable boxes with new pads or plastic boxes which have been freshly cleaned, sanitized and fitted with new pads. The boxes should have a

lining that provides good footing (such as excelsior pads or absorbent mats) and be constructed to allow adequate ventilation. The number of young in the box should take into consideration the outdoor temperature and transit time. Chick handling from hatcher tray through servicing (sexing, beak trimming, injection, etc.) should be controlled to avoid internal or external injury.

Boxes of young chicks should always be handled carefully and never thrown or dropped. If boxes must be stacked, care should be taken to insure adequate ventilation. If chicks are to be held in the hatchery, they should be placed in well ventilated rooms held at no less than 74°F (23.3°C) and 55 percent relative humidity. An air exchange of 25 cubic feet per minute (cfm) per 1000 chicks is recommended. Prior to hatching, the chick absorbs the remainder of the yolk sac into its body cavity. The yolk sac contents are rich in energy and moisture and can sustain the young bird for up to 72 hours, in the absence of food and water. However, chicks should be placed on feed and water as soon as possible after hatch.

Chick delivery vehicles should be properly ventilated to control temperature and humidity, and to remove carbon dioxide and provide oxygen (ventilation capacity 25 cfm/1,000 chicks). Chick deliveries should be scheduled early in the morning during hot weather to minimize heat stress whenever possible. Heat stress during loading and unloading of chicks can be critical.

Delivery trucks should be cleaned and sanitized after each delivery.

Beak Trimming

Many meat type strains are non-aggressive and do not require beak trimming. Beak trimming in the hatchery protects chicks from cannibalism later in life. If beaks are to be trimmed, a hot blade trimmer with a blunt blade should be used to notch the upper beak. By 10 days of age the tip of the upper beak will separate. An electric spark trimmer can also be used. The spark arcs between two electrodes and leaves a small hole in the beak. After a few days the tip of the upper beak will separate leaving a trimmed upper beak. These methods leave the tip of the beak intact until the chick learns to eat and drink which reduces early stress.

Hatchery Vaccination

Vaccination in the hatchery is essential to protect meat type chickens from Marek's disease and sometimes other disease agents. The vaccination program should be customized to protect

chicks from disease agents likely to cause mortality on the farm where they will be grown. Vaccines can be applied in the hatchery by injection or by spray methods (for details see HEALTH MAINTENANCE PROGRAMS page 11).

Vaccines can also be applied successfully by egg injection at the time of egg transfer from the setter to the hatcher. This procedure initiates an earlier immune response to protect chicks after hatching.

Hatchery Losses

Unhatched eggs and cull chicks should be humanely euthanized as soon as possible after the hatch is pulled. Carbon dioxide inhalation or maceration are acceptable methods of accomplishing this.

BROODING AND GROWING

Brooding Temperature

Newly hatched chicks are unable to control their body temperatures at extremely high or low ambient temperatures and must be provided a narrow temperature range for optimum health and growth. At hatch, chicks require an ambient temperature of 85 to 87°F (29.5 -30.5°C) or a cooler ambient temperature with supplemental radiant heat. Chicks can also be raised successfully in a cool room adjacent to an area (or hover) with a warmer temperature (95°F, 35°C at day-old). This is sometimes referred to as cool room brooding. As chicks grow and

feather out, their ability to regulate body temperature improves until about six weeks of age when they can control their body temperature within the ranges normally experienced in commercial poultry houses. Brooders should be started 24 hours in advance of chick arrival to warm litter and drinking water.

Litter

Chicks are often started on floors covered by two to four inches (5-10 cm) of new litter material. Several types of litter material can be used successfully. Wood shavings and rice hulls are preferred but chopped straw, peanut hulls, sawdust, and other materials are

sometimes used. The litter material needs to be free of chemicals, pathogens or other contaminants and should not be excessively dusty. Materials which are absorbent and have high insulating qualities are preferred. Litter can be reused if the previous flock has not

experienced health problems or unusual mortality. Wet and caked areas should be removed and new litter material added as required. With proper ventilation, litter can be maintained in good condition. If litter cake begins to develop, it should be removed or the litter should be stirred. Waterers are often moved at frequent intervals to avoid cake build-up.

Light For Brooding

During the first week, chicks should have a minimum light intensity of 1 foot candle (10 lux). Subsequently, the light intensity can be reduced to help control cannibalism.

Chick Guards

Chick guards are used to closely confine the chicks until they learn the location of the heat, feed and water. The area within the brooder ring is gradually increased in size and the guard is removed when the chicks reach 6 to 8 days of age. Guards may not be necessary if chicks are started in a more confined area such as with partial house brooding. Chick guards can be made of welded wire, metal, corrugated cardboard or any other suitable material. Guard

material should be 12 to 15 inches (30 to 38 cm) in height and long enough to form an ample ring around the heat source.

Feeding and Watering Procedures

Adequate numbers of feeders and waterers are important during the early life of chicks. Water is the most critical nutrient for the newly hatched chick. Chicks are often given water before feed to prevent dehydration and assure that they locate water sources. Water should

be in place 24 hours before chicks are introduced so that water temperature approximates ambient temperature. Feed may be introduced immediately or within a few hours of chick placement.

Feeding and watering equipment used to start chicks must be properly sized so that chicks can eat and drink comfortably. The edge of the feeder should be located at the average level of

the chicks' backs. Feed is often placed on egg flats or in plastic trays during the first few days to help chicks locate feed. Changes in placement of feeders should be made gradually so that the chicks find the new feeder locations.

Chickens should always be grown on diets which meet their nutrient requirements. Guidelines for nutrient requirements appear in the "Nutrient Requirements of Poultry" as published by

the National Research Council, National Academy of Science (1994). Feed should contain a mold inhibitor to protect against mold development and an antioxidant to protect fat soluble vitamins from oxidation. Prolonged storage of mixed feeds should be avoided. Feed should always be protected from rodents and moisture.

Poultry are fed diets comprised primarily of grain, protein supplements (e.g. soybean meal), minerals, vitamins and fat. By-product ingredients such as wheat bran, bakery byproduct meal, meat meal or dried brewers grain are sometimes used when they are cost effective. Approved growth promoters (e.g. bacitracin) and coccidiostats may be added to feed in small amounts. Mold inhibitors are often added to prevent the development of mycotoxins which are harmful to poultry. Hormones are not approved for poultry and are never included in the feed or water of

commercial poultry.

Space

Space required for meat type chickens varies with their size, housing and management system. Broiler chicks should be provided a minimum floor space of 72 square inches (465 cm2) per

bird up to 49 days of age if grown on litter.

CARE OF JUVENILE AND ADULT BREEDING STOCK

Care practices for replacement breeding stock should follow the general principles previously discussed for meat stock with the exceptions noted in this section.

Feeding

To achieve successful reproduction, meat-type breeding stock must be raised on a feeding program which limits growth rate and controls mature body weight. This requires feeding predetermined amounts of feed adjusted for the age, egg production, temperature and body weight of the flock. During the juvenile growing period, male and female chicks must be housed separately and grown on separate feeding programs to assure proper weight for

successful reproduction. Samples of males and females should be weighed at frequent intervals so that nutrition programs can be adjusted to maintain appropriate body weights throughout life. When the flock approaches sexual maturity, it should be transferred to breeder housing with an appropriate male to female ratio (usually about 15 males per 100 females). In the breeding facility, separate male and female feeders should be used so that the body weight of

both sexes can be controlled.

Nests

Nests for breeder hens should be properly sized to provide a comfortable environment for hens to lay. If nest holes are too large, more than one hen may attempt to enter the same nest resulting in injury and egg damage. One nest space should be provided for every 4 to 6 hens.

The nests should be maintained with clean nest pads or nest litter. Nest boxes should have perches in the front of the nest for safe entry.

Lighting

Developing pullets of meat-type strains which are exposed to increasing day lengths will begin laying eggs before they have reached optimum body size. This can result in excessive production of small eggs and these hens are more susceptible to prolapse of the oviduct

which often leads to death. To prevent these problems, pullets should be raised on short days (e.g., 8 hours) in a darkened house or on decreasing day lengths if housed in open-side housing. The day length should be increased to initiate lay when adequate body development and age have been achieved. Males should be light stimulated at least a week before females to assure good fertility at the start of lay.

Lamps in breeder housing should provide a minimum light intensity of one half foot-candle (5 lux) at the level of the feed trough.

Hens need to receive artificial light to maintain a day length of at least 14 hours to

initiate and maintain egg production. The lighting system should be controlled by a reliable timer which will turn the lights on and off at appropriate times. In open-sided houses, lights are normally used to supplement natural day length. The light schedule should assure that day length does not decrease. To achieve this, artificial day length must exceed the longest day at the latitude where the flock is located.

Egg Care, Handling, Sanitation and Storage

Eggs should be collected at least two times per day. If they are to be sanitized, this should be done as soon as possible after collection using an approved procedure. Only sound, nest-clean eggs are recommended for hatching. If floor eggs are to be set, they should be washed using an approved procedure, as soon as possible after collection and set in separate machines from nest-clean eggs.

Eggs which are stored before setting should be held in clean rooms at a temperature of 55 to 65°F (12.8 - 22.1°C) and 75 percent relative humidity. The higher temperature (65°F) is preferred for storage of 1 to 7 days. Eggs held more than 7 days will benefit by storing in plastic bags and turning daily.

ENVIRONMENT

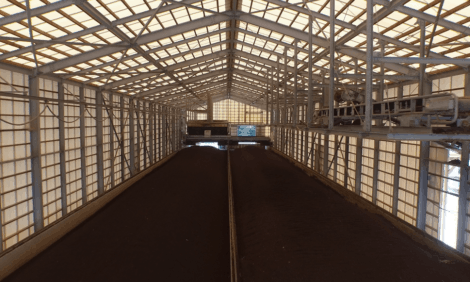

Housing

The purpose of a poultry house is to confine birds and protect them from environmental extremes which might increase mortality or reduce growth, immunocompetence, fertility or egg

production. Many types of structures are used successfully and houses may be constructed from materials which are readily available in the area. Wood frame or steel structures are popular. Some insulation is necessary in most climates to maintain a suitable environment. Interior surfaces which can be easily sanitized are preferred.

If environmental temperatures are expected to exceed 90°F (32°C), some provision is necessary for cooling. Successful systems include roof sprinkling, inside fogging, fans positioned to move air over birds, building insulation and evaporative pad cooling of incoming air. The amount of protection required varies with the severity of the environment.

Air Quality

The progression in poultry management from extensive to more intensive systems has resulted in increased bird density and concentration of their waste products. There is the potential for harm to both birds and workers if airborne contaminants exceed the limits recommended by the National Institute for Occupational Safety and Health.

Of the airborne contaminants, dust is the most obvious. Poultry house dust may be the product of feed, manure, litter, and/or dander. The California Division of Occupational Safety and

Health (Cal/OSHA) set permissible exposure limits for total and respirable "nuisance" dust at 10 and 5 mg/m3, respectively. Cal/OSHA defines nuisance dust as the total dust measured.

This is an industry standard measurement that approximates the total dust in the air.

Cal/OSHA also has established ammonia exposure limits for workers. The 8-hour TWA (time weighted average) exposure limit for ammonia is 25 ppm and the 15-minute short term exposure

limit is 35 ppm. While Cal/OSHA does not have a permissible exposure limit for endotoxins (derived from bacteria), employees exposed to endotoxins and dust can develop the following

symptoms: cough, chest tightness, diarrhea, eye irritation, fatigue, fever, headache, nasal irritation, nausea, and phlegm.

It is incumbent on the poultry manager to manage the environment so that dust, endotoxins, and ammonia levels are kept as low as possible. If these levels cannot be kept at a minimum,

efforts should be taken to reduce the employee-exposure time and provide respiratory protection in the form of a two-strap, OSHA-approved dust mask.

Ventilation

Ventilation is required to maintain good air quality for poultry and appropriate litter moisture for a healthy environment. Air exchange is necessary to remove carbon dioxide and ammonia from poultry houses and to bring in oxygen; however, removal of heat and moisture from litter houses usually requires greater air exchange than required for carbon dioxide and ammonia removal. Long term ammonia exposure of birds should not exceed 10-20 ppm. If this limit is consistently exceeded, damage will occur to lungs, trachea and eyes; young birds

are more sensitive than older birds. Ideal moisture levels for litter are 25 to 35 percent. Lower levels result in excessive dust which is detrimental to the respiratory system. Higher moisture levels result in excessive caking of litter which can contribute to breast blisters,

disease problems and lameness.

HEALTH MAINTENANCE PROGRAMS

The scientific definition of health in an animal is the absence of disease. Bacteria-free chickens in laboratory isolators grow approximately 15 percent faster than similar chickens in a "conventional" environment. This ideal cannot be achieved economically on commercial farms. The use of immunization, sanitation, preventive medications and biosecurity are discussed as the preferred preventives for infectious disease, with only occasional alternatives such as strategic medication.

Immunization

The planned deliberate induction of immunity is one of the most beneficial and effective management tools available for the prevention or suppression of infectious disease (as compared to the natural induction following unpredictable exposure to field infection).

There are two types of immunity: passive or active. Passive immunity occurs as antibody in the yolk of developing embryos; it is derived from the maternal bloodstream, and is present

for 2-4 weeks in the blood of newly hatched chicks. The presence and level of passive immunity in the chick is therefore dependent on the presence and level of antibody in the maternal parent. The goal of some vaccination programs is the production of high levels of passive immunity in chicks, e.g., for avian encephalomyelitis and infectious bursal disease. Passive immunity is generally effective against viral diseases, but less so or ineffective against bacterial infections, e.g., mycoplasmas or salmonellae.

Active immunity occurs when an antigen is introduced and processed through the bird's immune system, resulting in various protective responses. These responses include the production

of antibody and/or macrophage cells which will act to protect the bird if it is exposed to that antigen at a later time.

Active immunity can be produced either by living or inactivated antigens, or combinations of the two. Most living bacterial and viral antigens are either

naturally occurring strains of low pathogenicity (mild), or pathogenic strains whose virulence has been reduced by passage in laboratory media (attenuated). Live vaccines can be

administered either to individual birds, by injection or eyedrop, or to large numbers

of birds via the drinking water or by aerosol. Certain vaccines can be given by injection into the eggs before hatching. Building a high level of immunity often requires a second or third administration of vaccine, usually with a stronger vaccine strain on each occasion.

Inactivated vaccines must be given by injection. These usually incorporate potent adjuvants which enhance the local cellular reaction and therefore increase the immune response.

Development of Immunization Programs

The development of an immunization program should be based on knowledge of the diseases to which birds are likely to be exposed, and incorporated into the management system of the flock. It requires knowledge of the presence and level of passive immunity, so that immunization can be properly timed. Timing is also important so that vaccines do not detract from each other's responses, or exacerbate their clinical effects. Vaccines should not be

administered when other stressors are acting on the flock.

Vaccines should be purchased and used after consultation with vaccine manufacturers. Where serological monitoring tests are available, these should be routinely utilized following

vaccination to ensure that an immune response has taken place.

Limitations of Immunizations

Immunization must not be a substitute for poor sanitation and biosecurity. The borderline between clinical good health and disease is very narrow. Thus, immunization programs

may not totally protect birds which are stressed or are in unhygienic conditions. Deleterious conditions will also reduce productivity. Stressful conditions will render the birds more susceptible to disease organisms. In other words, animals that are constantly exposed to

environmental diseases do not grow and produce as well as those in well managed environments.

Cleaning and Disinfecting Houses and Equipment

Periodic cleaning and disinfection of commercial poultry houses are recommended to reduce disease agents. These may be performed once per year or more often if disease problems have

occurred. When poultry are removed from houses, the building and equipment should be carefully cleaned and disinfected before new birds are introduced. Manure (including litter)

should be removed from the immediate vicinity of the poultry houses and preferably from the premises.

A successful cleaning and disinfection protocol should include:

- Removal of all litter and manure.

- Washing down of the interior of the structure and all equipment, preferably using a high-pressure washer.

- Application of a disinfectant solution or fumigant.

Careful attention should be given to watering devices and lines to be sure that they are free of disease agents. Water lines should be flushed and a disinfectant solution pumped into the

lines. The lines should be closed and allowed to rest for at least 24 hours and then thoroughly flushed to remove the disinfectant.

Preventive Medication

Some disease agents can most effectively be controlled in commercial environments with preventive medications. These compounds are usually included in the feed. They function by disrupting the life cycle of the coccidia or other disease producing agents.

Farm Security

Biosecurity is the utilization of methods which can stop the transfer of infection into or between components of production systems. Biosecurity systems include the following components and

procedures:

- allow only necessary visitors on production sites;

- restrict movement of workers and equipment between houses, sites and age groups;

- provide foot baths or boot washing stations, showers and protective clothing at strategic points;

- maintain ongoing cleaning and disinfection programs, especially in hatcheries;

- reduce microbial load on trucks and equipment by washing and disinfecting at critical times;

- locate production sites strategically in relation to other production sites and movement of poultry to minimize disease transfer;

- restrict contact of workers with other poultry, especially potential carriers of hazardous disease organisms;

- control rodents and wild birds effectively, both are potential disease vectors;

- confine pets away from commercial poultry.

Monitoring Mortality

Daily flock mortality records should be maintained and monitored. Crippled, unthrifty, immobile or sick birds should be removed from flocks at frequent intervals to prevent spread of disease to healthy birds. Culled birds should be humanely euthanized. Any unusual level of mortality should trigger an investigation to determine the probable cause. If the cause is not readily apparent, a sample of freshly dead birds should be examined by management, a veterinarian or diagnostic laboratory. Routine examination of daily mortality is recommended as a method to monitor the

causes.

Dead Bird Disposal

Successful methods of dead bird disposal prevent spread of pathogens to surviving birds and result in appropriate recycling of nutrients without contamination of surface or ground water. The following methods are acceptable in commercial systems:

Rendering is a very acceptable method from an environmental standpoint but can expose the farm to pathogens if a rendering truck is used for pick up. It is highly desirable to establish a road side pick up area so the rendering trucks do not come onto the farm for more than a few feet. The rendering pick up area must be kept neat and should be screened from public view. It should be located downwind from the poultry houses if possible. This system is flexible and can accommodate a sudden increase in mortality. Storage containers should be fly-tight and pick up should be scheduled at least twice per week if the carcasses are not refrigerated.

Composting, if properly done, is a very acceptable method of carcass disposal and results in a valuable compost by-product which is an excellent soil amendment. A concrete pad is necessary to prevent leaching and a rain shelter to prevent excessive wetting of the compost. The composting process must be managed to assure that an adequate temperature is achieved to destroy pathogens. The system is flexible and can handle a sudden increase in mortality.

Incineration is effective from a disease control standpoint but units must meet local air pollution standards. Incinerators are expensive to operate, require energy input and cannot handle a sudden increase in mortality. Proper ash disposal is necessary to avoid pollution problems.

Disposal pits or burials are environmentally acceptable in soils where movement of nitrogen into groundwater is not a problem. Unfortunately, determining the suitability of a particular site for pit disposal or burial may cost as much as constructing a suitable composter, with no assurance of success. Pits work best with a constant load of mortality but do not handle sudden increases in mortality. Burial is a more flexible method.

MINIMIZING NUISANCE ASPECTS OF FARMS

Air Quality

Dust and other airborne particles may be generated on a production facility. The producer should pay particular attention to prevailing winds and avoid operations that create dust (house

clean-out, tractor work, etc.) on days when the wind will blow particulate matter onto neighboring property.

It should also be noted that while Cal/OSHA uses dust level exposure limits for healthy persons as official limits for the internal environment of poultry houses, air quality control boards use limits that are 10-100 times less than these for their environmental limits. The

term PM-10s is the regulatory term for dust particles smaller than 10 microns. These extremely small particles generate haze and can be minimized by use of cover crops and by paving roads

surrounding the poultry facility.

Manure Management and Odor Control

When removed from the poultry house, litter should be moved off the site as quickly as possible. If temporarily stored, it should be stacked in piles to prevent excessive wetting. Manure storage areas should be graded so that run-off from buildings and impervious surfaces does not run into the storage area. Run-off from the manure storage area should be confined to the site and should not drain toward the poultry house(s). Manure is a valuable fertilizer and soil amendment when properly handled.

Fly Control

Flies are unsightly and can transmit disease agents. Musca domestica, the house fly, is most active at temperatures between 80 and 90°F (26.7 - 32.2°C) and at a humidity of approximately 40 percent. The house fly is inactive below 45°F (7.2°C) and dies at temperatures below 32°F (0°C).

Fannia canicularis, the little house fly, is active throughout the year, but its reproduction peaks in the spring and fall. Therefore, fly control on California poultry farms is difficult during these seasons. Care must be taken to eliminate any areas that would be conducive to fly

breeding, such as wet areas in the litter, spilled feed outside poultry houses, etc.

Landscaping

The sight of an animal production facility, or especially of a manure storage area, may create the perception of nuisance in the minds of some individuals. The producer may effectively screen these entities from view with the use of appropriate shrubs and trees. Vegetative screens can also be

effective in reducing dust leaving the premises and will shield against the influx of airborne disease agents.

BIRD HANDLING AND TRANSPORTATION

The manner in which birds are handled will affect their reaction to the restraint. Birds should always be held in a manner that provides as much support as possible and reduces the likelihood of

the bird struggling which may injure its wings or legs. An appropriate manner in which to hold an adult chicken is to support the bird's breast in the palm of the hand while restraining the bird's legs between the handler's fingers or by holding both legs. When carrying an adult chicken from one location to another, the bird can be carried by both legs or both wings. The period of time a

bird is held in a vertical position, with its head down, should be minimized.

After handling, birds should be placed directly onto the floor or released from a low height that allows them to land feet down, without flying.

Catching

It is necessary to remove feed 8-12 hours before slaughter to reduce carcass contamination. The catching process should be as efficient as possible, minimize the stress on the birds, and be

done in such a way as to prevent piling of the birds. Dimming of the house lights or catching at night have long been employed to create a less stressful environment for catching.

The manner in which a market age bird is caught can have significant effects on carcass quality. All personnel involved in bird catching and transport operations should be given training in

appropriate bird catching and handling methods.

Loading

The crates, cages or bins used for live-haul should be properly constructed to allow loading, transportation, and removal without injury to the birds. All containers must be kept clean and in good repair. Stocking density will depend on the size of the crate, the size of the birds, and transportation conditions (transit time and temperature). When the crate is full, there should be sufficient floor space so that all birds can be resting simultaneously on the floor and each bird

should have free head movement.

During hot weather, birds should be moved during the cooler part of the day whenever possible. Additional space in transport containers will minimize heat stress. Trucks waiting to unload poultry at processing plants should be provided shade, fan ventilation and during very hot

weather, evaporative cooling. To provide for bird comfort, ventilation and bird density in transport containers should be adjusted with changes in weather. The time birds are kept on trucks should be minimized.

Vehicles

Vehicles must be kept clean and in good repair. The truck driver is responsible for assuring that all crates, cage doors, and bins are secured before leaving the live production site.

Transportation Conditions and Route

The driver should be prepared to cover the vehicle and protect the birds from possible severe winds and/or rain. Care must be taken that the loaded

vehicle is not left standing for any extended period of time. In the case of required stops (inspection stations, truck maintenance, etc.), the birds must be protected from environmental extremes and provided adequate air circulation. While the shortest route between the live production facility and the processing plant may seem most logical, the driver should avoid passing other sensitive poultry establishments, agricultural operations or residential areas.

PROCESSING

Procedures at processing plants should be designed to prevent unnecessary pain, insure maintenance of optimal meat quality and microbial safety, and preserve the product's visual appeal. Unloading

Care taken in unloading at the plant, will prevent injury of birds. While speed is of importance, it should not be achieved by inappropriate handling of birds, crates, or bins. The crates and

bins should never be tossed or dropped. If a mechanized system is used for unloading the crates from the truck, care should be taken so that the crates are never at an angle which would cause

piling of birds.

Shackling

Birds must be hung carefully on the shackles to avoid injury. The shackles should be size-appropriate to the age and species of birds being slaughtered.

Stunning

State or Federal Guidelines must be followed depending on the type of inspection being done at the processing plant. When stunning is employed, the electrical current is applied in such a manner that the animal be rendered insensible to pain. Stunning immobilizes the bird and prevents wing breakage, dislocation of joints and bruising. The instrument used for stunning should be safe for plant personnel and should deliver the required electrical shock (appropriate amperage may vary with equipment, age of bird, etc.).

Appropriate State and Federal regulations may be consulted for any exemptions based on the nature and/or size of the operation and those related to ritual slaughter (religious) practices.

Slaughter

Once stunned, birds are slaughtered by having the jugular vein and carotid artery cut with a sharp hand-held or mechanical knife. Again, all pertinent State and Federal regulations must be adhered to. Any exemptions which apply will be listed in the State or Federal Regulations.

BIBLIOGRAPHY

Agriculture Canada, 1990. Recommended code

of practice for the care and handling of

poultry from hatchery to processing plant.

Agriculture Canada Publication 1757/E.

Ottawa, Canada: Communications Branch,

Agriculture Canada.

Azavedo, J. and P. Stout, 1974. Farm animal

manures: an overview of their role in the

agricultural environment. Manual 44.

California Agricultural Experiment Station

Extension Service.

California Food and Agriculture Code. Section

19501.

Castellan, R.M., Olenchock, S.A., Kinsley,

K.B. and Hankinson, J.L., 1987. Inhaled

endotoxin and decreased spirometric values.

New England Journal of Medicine

317:605-610.

Curtis, S.E., editor, 1988. Guide for the Care

and Use of Agricultural Animals in

Agricultural Research and Teaching.

Consortium for Developing a Guide for the

Care and Use of Agricultural Animals in

Agricultural Research and Teaching.

Division of Agriculture, National

Association of State Universities and

Land-Grant Colleges, One Dupont Circle,

N.W., Suite 710, Washington, DC

20036-1191.

Esmay, M.L., 1978. Principles of Animal

Environment. AVI Publishing Co.,

Westport, CN.

Jones, W., K. Morring, S. Olenchock, T.

Williams, and J. Hickey, 1984.

Environmental study of poultry confinement

buildings. Am. Ind. Hyg. Assoc. J.

45(11):760-766.

Loomis, E.C., J.R. Anderson, and A.S. Deal,

1980. Identification of common flies

associated with livestock and poultry.

Leaflet 2506. University of California

Cooperative Extension.

National Research Council, 1994. Nutrient

Requirements of Poultry, 9th Ed. National

Academy Press, Washington, DC.

North, M.O. and D.D. Bell, 1990. Commercial

Chicken Production Manual, 4th Ed.

Chapman and Hall, New York, NY.

Parkhurst, C.R. and G.J. Mountney, 1987.

Poultry Meat and Egg Production. Van

Nostrand Reinhold Co., New York, NY.

Payne, V. and J. Donald, undated. Poultry waste

management and environment protection

plan. Circular ANR-580. The Alabama

Cooperative Extension Service, Auburn,

AL.

Stadelman, W.J., V.M. Olsen, G.A. Shemwell

and S. Pasch, 1988. Egg and Poultry-Meat

Processing. VCH Publishers, 220 East 23rd

St., Suite 909, New York, NY 10010-4606.

Title 8, California Code of Regulations. Sec.

5155, Airborne contaminants.

GLOSSARY

Adjuvant Additive to vaccine to enhance its effectiveness.

Antibody A protein molecule capable of combining specifically with an antigen.

Antigen A substance foreign to the host animal, commonly a disease agent or vaccine.

Bacterin A killed bacterial vaccine, consisting of a suspension of whole bacteria.

Biosecurity A management system to minimize the disease exposure of flocks.

Broiler/fryer A young chicken (usually under 8 weeks of age) of either sex (usually under 6

pounds in ready-to-cook weight).

Composting A natural decomposition process for organic wastes.

Cornish game hen A young chicken (usually 4 to 6 weeks of age) not more than 2 pounds in

dressed weight.

Dander Small particles of dead skin or feather particles.

Depopulation Removal of all animals from a premise.

Diet A feed prepared from a mixture of ingredients.

Endotoxins Toxins produced by bacteria.

Hatcher Incubator used during the final three days including the hatching period.

Immunity Resistance of a bird to disease challenge.

Litter An absorbent bedding material used to cover the floor in poultry houses.

Macrophage A cell which can ingest and destroy foreign cells such as bacteria.

Multi-age farm A farm with more than one age group of chickens.

Pad cooling An evaporative cooling system which uses wetted pads with fans to move the air

into or out of the house.

Prolapse An eversion of the terminal end of the reproductive tract with exposure of soft

tissues.

Pullet A sexually immature female chicken.

Rendering The conversion of dead animals to feed ingredients by cooking and separation of

fat from protein.

Replacement Young bird grown to replace breeding stock.

Roaster A young chicken (usually under 15 weeks of age) of either sex (usually 5 pounds

or more in ready-to-cook weight).

Serology Tests on blood serum to determine the level of circulating antibody to specific

disease agents.

Set (as an egg) Placed in an incubator to produce a chick.

Setter Incubator used during the first 18 days of incubation.

Shackles Metal hangers which hold poultry securely by the feet during processing.

Vector Carrier of a disease agent from one bird to another or even from one farm to

another.

To view ThePoultrySites own Glossary please Click here

To download the PDF version of this booklet (26 pages) Click Here

Source: University of California - May 1998