Changing pelleting conditions and challenges in the xylanase application

Longer conditioning times: beneficial for animal health, challenging for enzymesFor decades, pelleting has been a common practice in animal feed production. Especially in broiler nutrition, it is well-known for increasing energy efficiency and, consequently, improving performance (McKinney et al., 2004).

Longer conditioning times: beneficial for animal health, challenging for enzymes

In the early days of pelleting, the industry employed rising temperatures and conditioning times ranging from 15 to 30 seconds. However, in contemporary practices, extended conditioning times are becoming increasingly prevalent, offering several advantages:

- Enhanced pellet quality due to increased heat and moisture absorption

- Production of more durable and uniformly shaped pellets due to the formation of bonds between particles

- Improved gelatinization of starch

- Reduction in dust and wastage

- Enhanced feed palatability, and

- Mitigation of microbial growth.

Increasing the conditioning times proves to be a valuable tool in effectively reducing microbes, especially in combating salmonella and other pathogens. This improvement is crucial for enhancing the cleanliness of feed. It's not uncommon to see conditioning times of up to 6 minutes for breeder feed, 4 minutes for salmonella-free feeds in broilers, and 3 minutes for swine diets.

While these changes benefit animals' overall health and well-being, they pose a challenge to enzyme application. Enzymes, being proteins, are vulnerable to high temperatures, leading to denaturation and loss of functionality. The moist conditions further contribute to changes in the charge and shape of enzymes. Conditioning involving exposure to high temperature and moisture exacerbates this challenge, resulting in significant denaturation and permanent loss of enzyme activity.

How can we preserve enzyme activity effectively?

There are multiple ways enzyme suppliers deal with such a challenge in pursuit of preserving enzyme activity in pelleted feed.

1. Coating of enzymes

During the last 15-20 years, numerous enzyme suppliers have used coating technology to protect their enzymes. Unfortunately, this benefit is compensated by certain disadvantages:

Uneven coating leads to less uniformity and lower effectiveness

Coating processes may not always result in a consistent covering of enzymes, possibly leading to variations in enzyme activity and efficacy. An uneven distribution within the feed can lead to animals failing to meet performance expectations.

Stability and storage may be impacted

Coated enzymes may have reduced stability during storage, especially if the coating is not effectively designed to protect the enzyme from degradation over extended periods. Storage conditions and shelf life must be carefully managed to maintain enzyme efficacy.

Effect in the animal may be impaired

Depending on the type of coating material used and the coating quality, the effectiveness of the enzyme can vary. Too strong protection of the enzyme can lead to reduced availability in the GIT because of insufficient release or, in the case of inadequate coating, excessive release before reaching the target site for digestion. Both inaccurate coatings negatively impact digestibility and animal performance.

Coating can negatively impact the environment

Some coating materials may have environmental implications, especially if they are not biodegradable or release harmful substances into the environment during degradation.

While coating may offer some protection against high temperatures, its efficacy under more extended conditioning times remains uncertain, as most tests are conducted with shorter durations of 15-45 seconds versus 120-180 seconds or even longer, which is becoming the new norm.

2. Liquid application post-pelleting

Some enzyme suppliers started offering liquid enzymes for post-pelleting liquid application to deal with the lower inherent thermostability of their enzymes. This was not ideal, but a way around resolving the challenges of high temperature and longer conditioning time during the pelleting process. However, in-depth discussions with feed mill operators and nutritionists reveal that this approach poses some serious hidden challenges:

Shorter shelf life

Liquid enzyme formulations usually have a shorter shelf life. This is particularly challenging if the enzymes must be shipped long distances.

Feed mills need additional equipment

Liquid enzymes are applied by a post-pelleting liquid applicator system (PPLA). This brings additional engineering with additional maintenance and pit stops, affecting the overall throughput of the feed mill and increasing the costs.

In some cases, adjusting the pelleting machines to the output of the PPLA’s spray nozzles to ensure a homogenous and even application of enzyme on the pellets may reduce the overall pellet production rate, especially in big feed mills with very high throughput.

Uniform distribution of the enzyme is challenging

The homogeneous and uniform spraying of the enzyme solution on the pelleted feed requires meticulous attention. For example, blockage of spray nozzles with dust particles hindering spray and going unnoticed is not uncommon. As enzymes are applied with a certain nutrient matrix value in feed, the inadequate distribution of the enzyme can impact animal performance.

3. There is a better way: Intrinsically thermostable enzyme

The biotechnological advances in enzyme development, especially in enzyme discovery and engineering, enable us to develop intrinsically thermostable enzymes that sustain higher temperatures and longer conditioning times.

One such xylanase, Axxess XY from EW Nutrition, was an outcome of this dedicated innovation approach to solve this issue of high temperature and longer conditioning time. Axxess XY is intrinsically thermostable and, therefore, needs no coating. Axxess XY originates from a bacterium called Thermotoga Maritima. This bacterium is isolated from hot water springs near volcanic grounds. This gives Axxess XY an evolutionary advantage to sustain high temperatures but also very moist conditions.

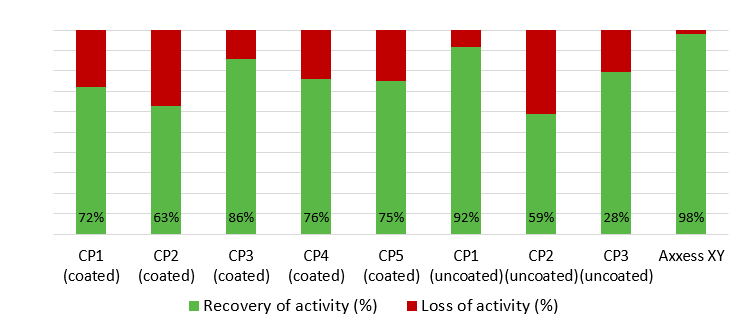

Axxess XY outperforms competitors under dry heat conditions

In rigorous testing under extreme dry heat conditions at 90°C for 60 minutes, Axxess XY exhibited remarkable performance, surpassing all tested coated and uncoated xylanases from global suppliers (see Figure 1).

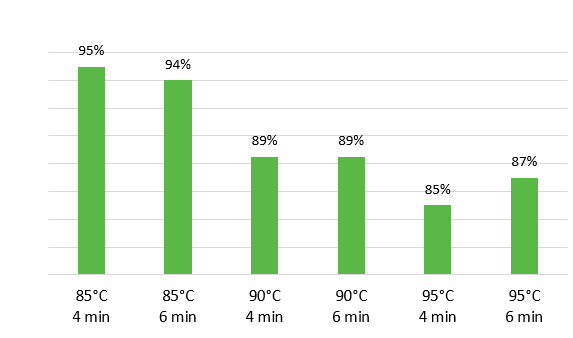

Axxess XY withstands conditioning at high temperatures and long time

Furthermore, to assess the stability of Axxess XY under practical conditions with high temperature and longer conditioning times, Axxess XY was incorporated into a commercial broiler diet (corn, wheat, soya mixed diet) and subjected to temperatures of 85°C, 90°C, and 95°C for 4 and 6 minutes. The study revealed over 85% recovery even at 95°C and 4 to 6 minutes of conditioning time (see Figure 2).

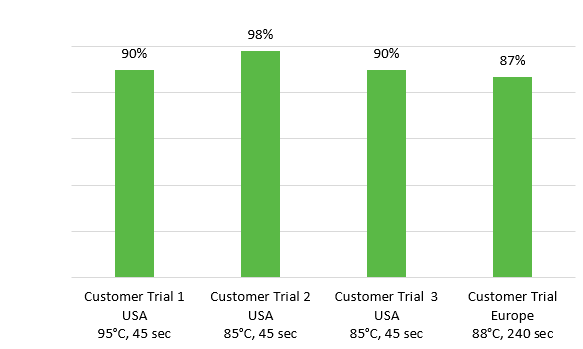

Axxess XY thrives in the rigorous pelleting environments of commercial feed mills

In practical application tests across various commercial feed mills with diverse conditioning processes, Axxess XY consistently demonstrated high recovery rates, confirming its suitability for real-world conditions (see Figure 3).

Conclusion: Meeting future challenges in feed processing

With the escalating pelleting temperatures and extended conditioning times aimed at enhancing feed hygiene, enzymes face increased challenges. Axxess XY, with its outstanding performance under demanding conditions, exemplifies the kind of innovation needed in enzyme technology. It not only provides confidence to animal feed producers with ease of use in diverse processing conditions but also assures nutritionists that the enzyme effectively reaches animal intestines, promoting better digestion and overall performance. As feed processing evolves, such innovations become crucial to meet future demands.

Axess XY launches officially on March 13 at VICTAM, in Bangkok.

| References | ||||

|---|---|---|---|---|

| McKinney, L.J., and R.G. Teeter | ||||

| (2004) | Predicting Effective Caloric Value of Nonnutritive Factors: I. Pellet Quality and II. Prediction of Consequential Formulation Dead Zones. Poultry Science | 83, no. 7 (2004): 1165–74 |