Chick quality and grading

1. What is Chick Quality? – It is a very subjective area and the criteria can differ greatly, depending upon who you ask.

Hatchery manager - Wants as many chicks as possible – should be maximum number of grade A chicks.

Sexer – Prefers fresh chicks with enough meconium.

Broiler manager – Wants fresh chicks with good vitality, clean beaks and navels and low mortality levels.

Veterinarian - Wants chicks with good vitality and clean, well-healed navels.

There have been several chick quality monitoring systems or assessments developed over the years, but unfortunately they do not often correlate with 7-day mortality levels.

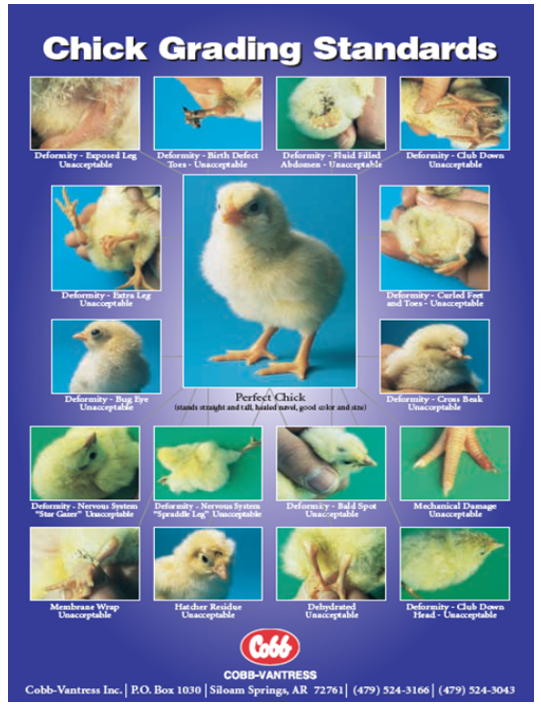

2. Chick Grading – Below are typical characteristics identified in the hatchery for good quality chicks.

Traditional observations of chicks:

- Stand tall/upright

- Clear, bright eyes

- Clean, well-healed navel

- Good feather covering

- Colour – not pale chicks

- Few defects – toes, legs, beaks, etc

- Infection free – yolk sac, omphalitis

New concepts that are being used to try and correlate chick quality measurements to broiler performance include:

- Chick weights/uniformity

- Day-old chick length

- Eggshell temperatures

- Cloaca temperatures

- YFBM (residual yolk weight)

- Chick yield % (chick weight as a % of egg weight)

- Organ weights (heart, gut, gizzard) – but this is destructive

- Enzymatic activity and oxidative stress from blood samples

- The best parameters are those that strongly correlate with final broiler performance (7-day weight and 7-day mortality)

At Cobb, we have also tried to implement our own chick quality scoring assessment in conjunction with chick yield percentage and cloaca temperatures which we regard as key contributors to mortality levels.

3. Key factors affecting chick quality – Listed below are some common areas where chick quality can be compromised and/or cause higher 7-day mortality levels.

- Temperature: Too high/low or significant variations can influence

- Hatching times (too early/too late)

- Chick weights (absorption of the yolk)

- Hatchability levels

- Cull rates

- Incidence of ‘red beaks’

- Humidity:

- Chick yield percentage and 7-day mortality

- Incidence of ‘red hocks’

- Navel quality

- Chick Holding – This area is often underestimated. After spending 21 days to produce a good quality chick, it is easy to compromise chick quality with 30 minutes of adverse holding environments.

- Poor or inadequate ventilation or air movement, resulting in chicks overheating and panting.

- Lack of air volumes/movement (oxygen) causing listless and ‘flat’ chicks in the boxes.

- Too cold/draughts (over-ventilating) causing chicks to ‘huddle’ in the boxes.

- Boxes stacked too close together.

- Too many chicks in a box.

- ‘Dead spots’ in the room for air flow/circulation.

Typical signs of over-incubating –

Red Hocks – are normally associated with insufficient moisture loss (especially in the incubators), causing a small air cell. This small air cell can weaken or affect the vitality of the chick due to reduced oxygen availability, resulting in damage to the hocks from trying to force itself out of the shell rapidly.

Navels – are normally related to either or a combination of high temperatures and high humidity levels, predominantly in the hatcher.

Chick Yield Percentage - The rule of thumb for incubation is that the chick should weigh two-thirds or 67% of egg weight. In antibiotic-free environments, we have seen a clear correlation with adverse chick yields and 7-day mortality levels. This can also include the hatching times of chicks as they mostly coincide. Late hatching chicks (fresher chicks) have more residual yolk present and higher chick yield percentage, whereas earlier hatching chicks have absorbed more yolk and produce lower or normal chick yield percentage (66 to 68%). When more yolk is present, the chick is more susceptible to secondary infections from stress factors, leading to E. coli infections or bacillosis. As the chick consumes feed and water at the farm, the bacteria multiply resulting in high mortality levels from 2 or 3 days to 6 days of age.

The table below highlights how later hatching chicks (in the last 12 hours before take-off) had the highest chick weight, lowest 7-day bodyweight, highest chick yield percentage and 7-day mortality level. These trials have been repeated several times and show a consistent result.

4. Summary - The key measurements to determine ‘Chick Quality’ are –

- Chick Yield Percentage - (66% to 68%)

- Eggshell Temperatures – at transfer 37.7 to 38.0°C (100.0 to 101.0°F)

- Cloaca Temps – controlled, consistent, no panting/huddling 40.0 -40.6°C (104 to 105°F

- Hatch Window – not too fresh for local farms

- Try the Cobb measurement system to see if there are correlations