Chick Quality Hatchery Impact on Performance

This presentation explains that today’s hatcheries must not look at hatch only. Although, companies seem to make hatch a priority, we all must remember that integrated as well as independent companies are in the meat business.There are many things we can do or not do to improve field performance. They require a properly set up and a well-maintained hatchery. They need proper equipment for ventilation and incubation. Just as important is the proper implementation of effective programs.

We start with the egg. We need good clean hatching eggs entering the hatchery. Dirty, cracked, inverted and cull eggs produce bad results. We need to ensure that these do not enter the incubator.

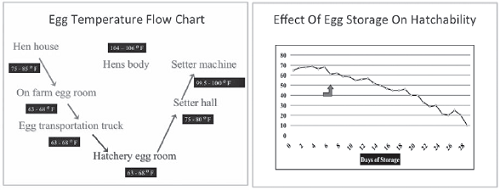

Egg size is important too. The minimum size must be agreed on. Remember that a chick will yield approximately 68% of the egg size. Therefore, a small egg will produce a small chick. Then we need to ensure correct egg storage from the farm to entering the setter. Fluctuating temperature will decrease hatch percent. Good air circulation is also important.

Next is maintenance on ventilation and incubation equipment. Vital to proper incubation as well as hatch and chick quality is a preventive maintenance program that is well implemented and followed at all times. Such a program includes calibration of all equipment. Controls are measured. All doors, racks and curtains are in good working condition and position. All fans are at the correct pitch and rotating at the correct RPMs. Dampers and cooling coils are adjusted correctly.

A proper embryodiagnosis should be performed on all flocks and all incubators. This can be time consuming but is one of the most valuable tools available to management. It reveals true fertility and incubator performance. The analysis must include hatch efficiency. The preferred method presented here is hatch-of-fertile. As flocks mature from young to old, the hatch-of-fertile will change too.

Another metric to diagnose is egg storage time on all flocks. As storage time increases, hatch will decrease. This always needs to be factored into hatch-of-fertile. See the charts below.

Another consideration is the set-transfer-pull program. It is important that once we design a program for a certain number of incubation hours, it is followed precisely. Egg set time differs according to certain production conditions. For example, flock age and egg age. However, transfer time needs to be consistent.

Once the chicks are transferred from the setter to the hatcher, it is important that we implement a step-down profile. Remember, eggs enter the hatcher as embryos and come out as baby chicks. Vital to performance, is that the baby chicks do not get hot. Once the chicks have hatched, chick holding begins and continues until delivery. Therefore, there are several areas that we include in chick holding. These are the hatcher, the pull/separator room, chick processing/holding and transportation. Temperatures need to be monitored at regular intervals in all of these areas. Our target temperature, from hatcher to delivery, is 103.5 - 104.5 °F.

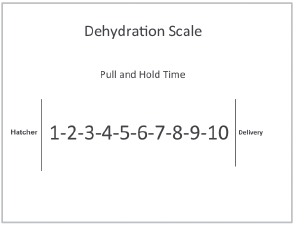

It is important also that hatchery management considers timing from chick pull to delivery. An example is, if we are 1 hour from pull to delivery we do not want to pull our chicks early (green). They need to be dry before loading onto transport. See chart below. Some complexes average 30 minutes from hatchery to delivery others can average as long as 10 hours. Unmanaged timing can cause improper growth and uniformity issues as illustrated in the presentation.

It is important also that hatchery management considers timing from chick pull to delivery. An example is, if we are 1 hour from pull to delivery we do not want to pull our chicks early (green). They need to be dry before loading onto transport. See chart below. Some complexes average 30 minutes from hatchery to delivery others can average as long as 10 hours. Unmanaged timing can cause improper growth and uniformity issues as illustrated in the presentation.

The bottom line is that a hatchery needs to be well managed and properly maintained at all times. In doing so, it can maximize hatch efficiency and field performance consistently. Hatcheries have a vital role in any company’s profits.

Scott MARTIN

LLC, USA

_________________________________

Information from the Avian Flu Forum hosted by Boehringer on April 2017