Cobb Breeder Management Guide: Disinfectants and sanitation program monitoring

Learn more about disinfectant types and microbial samplingPart of Series:

< Previous Article in Series Next Article in Series >

Editor's note: This article is an excerpt from the Cobb Breeder Management Guide and additional articles will follow. The Guide was designed to highlight critical factors that are most likely to influence flock performance. The management recommendations discussed were developed specifically for Cobb products. The recommendations are intended as a reference and supplement to your own flock management skills so that you can apply your knowledge and judgement to obtain consistently good results with the Cobb family of products. To read or download the complete Guide or to view Cobb's other management guides, click here.

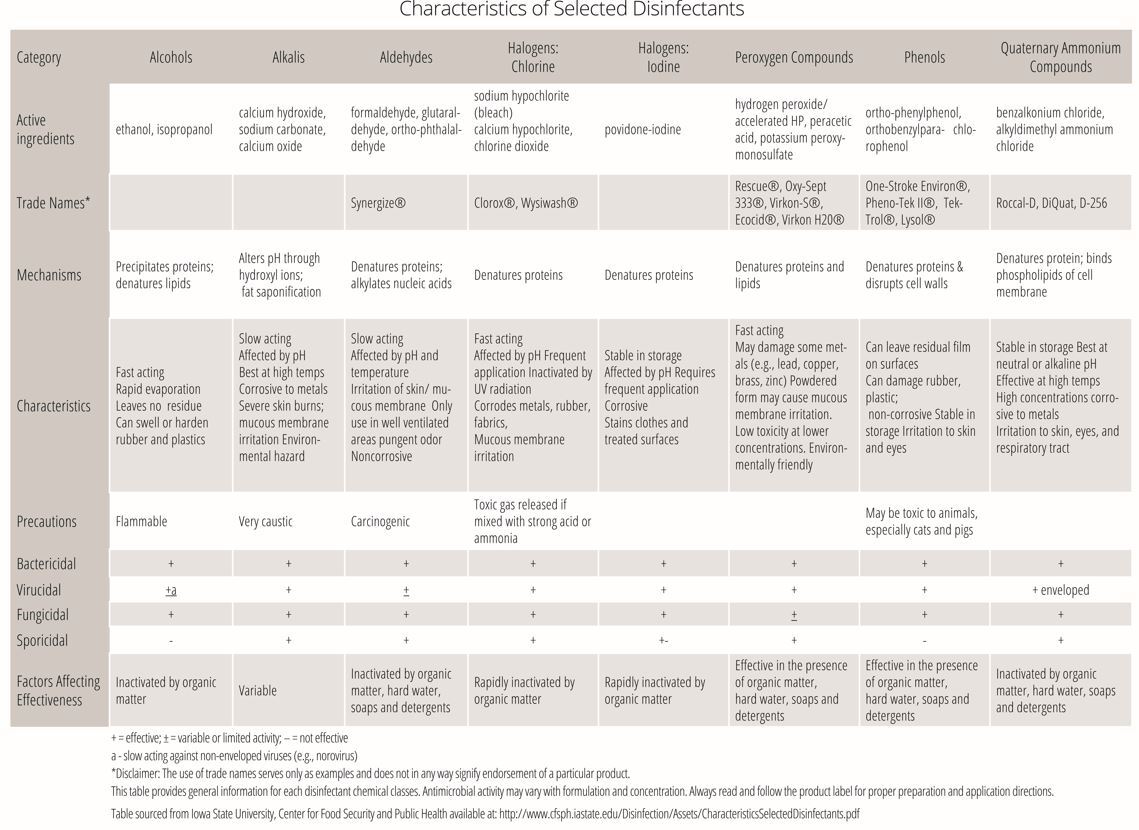

Most disinfectants are dissolved in water and contact lasts until the applied solution is dry. Foaming disinfectants can increase the contact time as it takes longer to dry, and consequently the antimicrobial activity of the disinfectant is extended. Cleaning with detergents can reduce the microbial load by 80%. Disinfectants can reduce the microbial load by an additional 20%. However, disinfectants will not be effective on dirty surfaces. All surfaces must be clean prior to applying disinfectants. Most disinfectants work best at temperatures above 20 °C (68 °F), but follow the manufacturer’s recommendation for the dilution rate and the diluent water temperature. Hot disinfectant solutions penetrate and disinfect better than cold solutions. This is especially important with porous surfaces. No single disinfectant works for all purposes. The product chosen should have proven effectiveness in tests against the relevant organisms in the region. Disinfectants can be inactivated by organic matter and inactivated by pH extremes, soap residues and minerals in the water. Care should be taken to ensure that the disinfectant is not corrosive to the target surface.

The efficacy of disinfection depends on:

- quality of cleaning

- hardness of water

- quality and suitability of disinfectant

- correct dilution and application

Disinfectants are grouped based on their chemical structure:

- halogens (iodophors and chlorines)

- alcohols

- oxidizing agents (hydrogen-peroxide)

- phenols

- aldehydes (formalin)

- quaternary ammonium compound

Chemical safety

Personnel must be aware of any chemical hazards disinfectants may pose. Personnel must be trained correctly to use any equipment involved in chemical applications. Training should deliver information so that workers are aware of the properties of every chemical used and they understand terminology of chemicals and chemical safety. Control measures, including the use of personal protective equipment (PPE), are mandatory when working with chemicals to protect against exposure. Safety Data Sheets (SDS’s), and compatibility charts should be available for finding hazard information about disinfectants and other chemicals. All chemical containers should have the original manufacturer’s label and chemicals should never be poured into non-labelled containers for storage. All chemicals (toxic and non-toxic) should be treated as though they were toxic.

Chemical storage

Segregate chemicals in storage according to hazard class to prevent reactions. Ideally, store chemicals in separate cabinets. Flammable chemicals such as alcohols should be stored in a flammable storage cabinet. Chemicals should be stored in appropriate containers to prevent leakage and inactivation. Store chemicals under the appropriate environmental conditions including temperature and humidity ranges. Check the manufacturers’ label for these storage requirements.

Formaldehyde

Formaldehyde can be a very effective disinfectant. However, formaldehyde is carcinogenic and not all countries and regions permit the use of this chemical. Check with your local regulations before you consider using formaldehyde as a disinfectant. There are also several very effective disinfectants that are available (see table below).

Sanitation Program Monitoring

To monitor the effectiveness of the sanitation program, a visual inspection and sampling for microbes is suggested. The effectiveness of the sanitation program can be measured using quantitative and qualitative laboratory tests. Sterilization of the facilities is not realistic but microbiological testing can confirm that all undesirable organisms including Salmonella have been eliminated. A documented audit including both visual and microbiological testing and attention to the performance of subsequent flocks can support the effectiveness of the sanitation program. Some key points for a sanitation monitoring program are listed below:

- A minimum of ten swabs per house should be taken for laboratory analysis.

- It is impossible to sterilize a house, but it is possible to reduce the number of microorganisms. The bacterial counts or total viable count (TVC), are used as an indicator for the effectiveness of the house cleaning procedures. The maximum total viable count in colony forming units per cm2 of floor area should not exceed 1,000 (TVC) and maximum 100 (TVC) for all other surfaces. No Salmonella should be isolated after cleaning.

- Maintain a rigorous vermin control policy including an anti-rodent barrier against the outside house or unit perimeter.

- Always keep the doors shut to prevent re-introduction of vermin and other contaminants. Seal any gaps or cracks in doors and walls. Openings around doors and walls can give rodents and insects access into the houses, compromising the biosecurity of the flock.