Cobb Breeder Management Guide: Egg handling

Learn more about egg collection and packingPart of Series:

< Previous Article in Series Next Article in Series >

Editor's note: This article is an excerpt from the Cobb Breeder Management Guide and additional articles will follow. The Guide was designed to highlight critical factors that are most likely to influence flock performance. The management recommendations discussed were developed specifically for Cobb products. The recommendations are intended as a reference and supplement to your own flock management skills so that you can apply your knowledge and judgement to obtain consistently good results with the Cobb family of products. To read or download the complete Guide or to view Cobb's other management guides, click here.

Maximum hatchability and chick quality can only be achieved when the egg is held under optimum conditions between laying and setting in the incubator. Once laid, its hatching potential can at best be maintained, not improved. If mishandled, hatching potential will quickly deteriorate.

- Manual nests should be well maintained with clean shavings. Any droppings, broken eggs and soiled material must be removed promptly from the nests and replaced with clean fresh nest material. In early production hens will tend to scratch the shavings out if nests are over filled. Hens prefer to make a concave type nest shape which can be done when shavings are placed inside and will make the nest more inviting for the hens.

- Frequent walking through the flock after onset of lay (point of lay) is a good management technique to minimize floor eggs. Walking the flock will disturb birds that are looking for nesting sites on the litter or in the corners of the house and encourage them to use the nest boxes.

- Egg temperatures within the nest, particularly during hot weather, may be similar to those in an incubator. Therefore, eggs must be regularly collected and cooled down to storage temperatures (21 to 25 °C ; 70 to 77 °F) to slow pre-incubation and embryo development. This will reduce embryonic mortality and improve hatchability.

- Egg collection from mechanical nests should be timed to prevent the risk of pre-incubation. The morning should be used to collect hatching eggs, and the afternoon can be used for house and bird management, as well as repairs/maintenance.

- Wash hands before and after each egg collection, and before and after handling floor eggs.

- Hand collect eggs at least four times daily and during peak production periods six collections are recommended.

- Always handle eggs carefully to prevent cracks. Eggs should be collected in plastic or fiber trays. When carrying by hand, egg trays should be stacked and carried at a maximum of 3 tiers high.

- Do not use baskets or buckets as they cause cracked and contaminated eggs.

- With mechanical systems, do not allow eggs to accumulate on collection tables. Adjust the system to a speed that allows egg collectors to work comfortably.

- In manual nests, when collecting eggs, close the lower nests before the last round of egg collection and leave the upper nests open. At the last collection, close the upper nest to help maintain cleaner nest conditions.

- With the mechanical community nest, open the nests 1 hour before the lights are turned on and close the nests 12 hours after the lights are turned on.

- Use of floor eggs decreases hatchability and is a hygiene risk. Never put floor eggs into nest boxes. Collect, pack and clearly identify floor eggs separately from nest eggs. If floor eggs will be incubated, they should be incubated and hatched in machines dedicated for floor eggs.

Automatic egg packers - Key points and considerations

Many large parent stock operations with community nest systems are further automating the farms by connecting the houses with a centralized egg packer.

- Centralized egg packer machines have a range of hatching egg (HE) collection capacities. A 10,000 HE/hour machine is considered sufficient capacity for a 30,000 to 40,000 parent stock farm. A 15,000 HE/hour machine is regarded as sufficient capacity for a 60,000 to 70,000 parent stock farm.

- All egg packing work should be completed in around 4 to 5 hours every day. Use the egg packer only once per day to minimize system wear if the egg belts total 50 cm in width and there is a separation between the 2 egg belts. If the egg belts are not separated and are smaller (only 20 cm wide) consider, as a minimum, 2 to 3 egg collections per day to reduce eggshell cracks and micro fractures. In this case, eggs should be packed 2 to 3 times a day and placed directly in the egg storage room.

- The egg packer machine can place the eggs in a carton or directly on hatchery trays, depending on the level of automation.

- Ensure the correct egg identification stamps are available, especially for export products.

- Egg trays (30 to 150 eggs) can be filled on site (egg tray stacking).

- Egg packers may operate with or without egg tray stacking.

- Paper egg trays must be dry and stored in a dry room for the easy separation during the packing process.

- The presence of many small feathers and dirty eggs indicates the nests are not closing or closing too late.

- Use a good light source (warm light) at the packer to ensure all hairline cracks are removed.

- Maintenance teams need to lubricate all moving parts on a weekly basis.

- Work areas should always be kept clean.

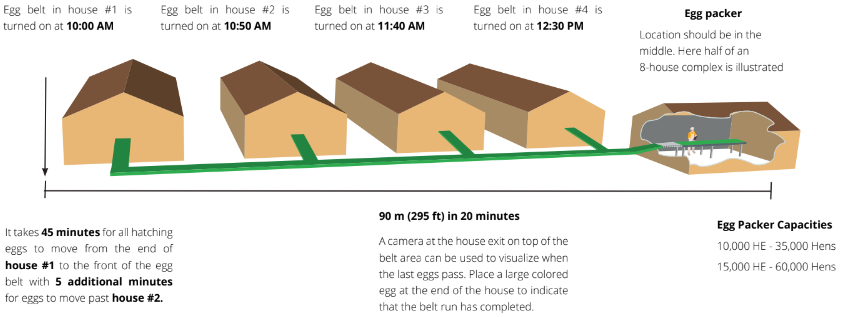

Egg collection timing

Egg collection timing given here is shown as an example. Egg belt speeds are adjustable and the manufacturer of the egg collection equipment can provide more information on adjusting egg belt speeds and timing. The following concept can only be used when the house temperature is below 22 °C (72 °F) to prevent pre-incubation of eggs on the egg belts. Since each house is collected in sequence, the time collection starts in successive houses is delayed by the time necessary to collect the previous house (see illustration below). For example, the furthest house collection starts 7 hours after lights on. The second house will begin collection 45 minutes later with an additional 5 minutes for eggs that are on the belt to move past the next house (i.e. 7 h 50 min after lights on). When the third house starts collecting eggs, the total time from the start of lights turned on is now 8 h and 40 min. For successive houses, close to 100 % of the daily production will be on the belt as a result of the timing.

Normally, eggs in the first and second houses are being collected while production continues. In this case, these houses can still contain up to 10 % of the daily production after the first collection. Therefore, after the first collection from all the houses, a second collection begins with the first and second house. During this second collection, most of the daily egg production should be collected. Since the first house was collected before all eggs were laid, a second round of collection can be done by increasing the belt speed to collect all eggs in 10 to12 minutes.

An example of egg packer set up and timing

Lights are turned on at 3:00 AM and belts are turned on 7 hours later beginning with house #1 (furthest from the egg packer).

Egg belt speeds

- When the house temperature is below 22 °C (72 °F) (to prevent preincubation of eggs on the egg belts) start the egg packer 7 hours after the lights come on and most of the production is on the belt. This is only feasible with community nests that have 2 belts of 25 cm (10 in) wide and a separation between the belts to minimize hairline cracks.

- Always start collection of the HE with the furthest house. A 100 m (330 ft) long house will require about 45 minutes to bring all the eggs to the connector belt.

- A 100 m (330 ft) corridor collector belt will require ±20 minutes to bring all the eggs to a central packer when all belts are at a fixed speed.

- Keep several meters between the last eggs of one house and the first eggs of the following house to track individual house production.

- Installation of an egg counter at each house belt exit, before the eggs go on the connector belt, is a good practice.

- After the first collection from all the houses, as second collection begin with the first houses that still have some eggs left on the house belts.

- During the second collection, most of the daily egg production should be collected (>99 %).

- In the first 8 hours after the lights come on, more than 90 % of the hatching eggs will have been produced by the birds.