Cobb Breeder Management Guide: Egg weighing

Learn more about egg weighing, hygiene, grading and qualityPart of Series:

< Previous Article in Series Next Article in Series >

Editor's note: This article is an excerpt from the Cobb Breeder Management Guide and additional articles will follow. The Guide was designed to highlight critical factors that are most likely to influence flock performance. The management recommendations discussed were developed specifically for Cobb products. The recommendations are intended as a reference and supplement to your own flock management skills so that you can apply your knowledge and judgement to obtain consistently good results with the Cobb family of products. To read or download the complete Guide or to view Cobb's other management guides, click here.

Egg Weighing

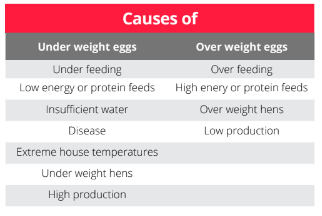

There are considerable advantages in weighing a sample of eggs each day to establish the trend in egg weight. The analysis of this trend is a useful guide for flock performance and will give an early indication of problems. Egg size is partly determined by the bodyweight of the females at photo stimulation, the development between 21 and 25 weeks of age, and the extent to which females become over weight after peak production. Delays of photo stimulation will result in larger eggs initially and throughout the life of the flock. Eggs over 70 g tend to have a poor hatch and can considerably affect the average hatchability of the flock. This is likely the reason for a more rapid decline in hatch after 50 weeks of age. The egg weights shown in the Cobb supplements (available at Cobbgenetics.com) should be expected from normal parent flocks when our recommendations for bodyweight, feed levels and feed specifications are followed. In the egg collection room, bulk weigh at least 90 eggs immediately after the second egg collection, which usually occurs around mid-morning. Make sure to exclude double yolks, misshapen, very small and cracked eggs. Daily egg weights, when plotted on a graph, will give an indication of potential problems that should be investigated immediately.

Automatic egg weighing

Many egg packing machines weigh all the eggs. Regular calibration of the scale is necessary to prevent hatching eggs loss. In the first 8 weeks, the maximum weight needs to be adjusted twice weekly to prevent larger eggs being mistaken for double yolks. A 1 g difference in maximum weight can have a large impact. Always set the minimum weight requested by the hatchery.

Managing egg weight

Egg weights are important to maintain in the latter part of the production period as weights impact eggshell quality, hatchability and chick quality. Investigations and field experiences report that eggs over 70 g tend to hatch less and have more late embryonic mortality when not enough cooling is available in the hatchers. Try to maintain an average egg weight below 70 g for as long as possible!

Typically, egg weights will increase during production but should be controlled to increases of 1 gram every 2.5 to 3 weeks after 35 weeks of age. Ideally, average egg weight should be close to 70 g between 55 and 60 weeks of age.

The following recommendations can be used to control egg weights:

- Control female bodyweights into peak production and after peak production. This involves adjusting and optimizing peak feed amounts and reducing the feed after peak correctly.

- Change from breeder-1 (B-1) to breeder-2 (B-2) feed when the egg weights reach 60 g in Cobb FF and 62 g in Cobb SF. Cobb recommends only B-1 and a B-2 feed be used because, with the proper reduction in feed amounts, the hen weight and egg weights should be controlled.

- Start production on time. It will take a hen longer to reach a 60 g average egg weight when production begins at 24 weeks compared to 25 weeks. A lower egg weight at 30 weeks indicates, in general, that the egg weight will be lower at 40 and often 50 weeks of age.

Egg Hygiene

Under certain conditions, it may be beneficial to sanitize hatching eggs. Peracetic acid can be used as an alternative. Fumigation or disinfection of hatching eggs on the farm should be applied as soon as possible to prevent bacterial penetration before the cuticle matures. Eggs should be treated with chemical-based antimicrobials — scraping, rubbing, or washing the eggshell will damage the cuticle and remove the physical and antimicrobial barrier. Do not wet hatching eggs with liquid sanitizers. Only under low humidity conditions will this procedure be an acceptable tool to reduce contamination. Since the eggshell permeability increases after 24 hours and makes the eggs more susceptible to bacterial invasion, the eggs should be sanitized as soon as possible. Thus, if fumigation or disinfection on the farm is not possible, eggs should be sanitized at the hatchery as soon as they are received.

Important management practices:

- Rejected eggs should be stored well away from hatching eggs.

- It is essential to place hatching eggs carefully into the transport tray with the small (pointed) end facing down.

- The egg handling room must be kept clean and neat.

- Nest pads in mechanical nests should be kept clean especially with older flocks.

- Maintain good vermin control in the egg store.

- The egg handling room is the first stage of egg cooling and it is advantageous to keep it cooler than the laying house, but warmer than the egg storage room.

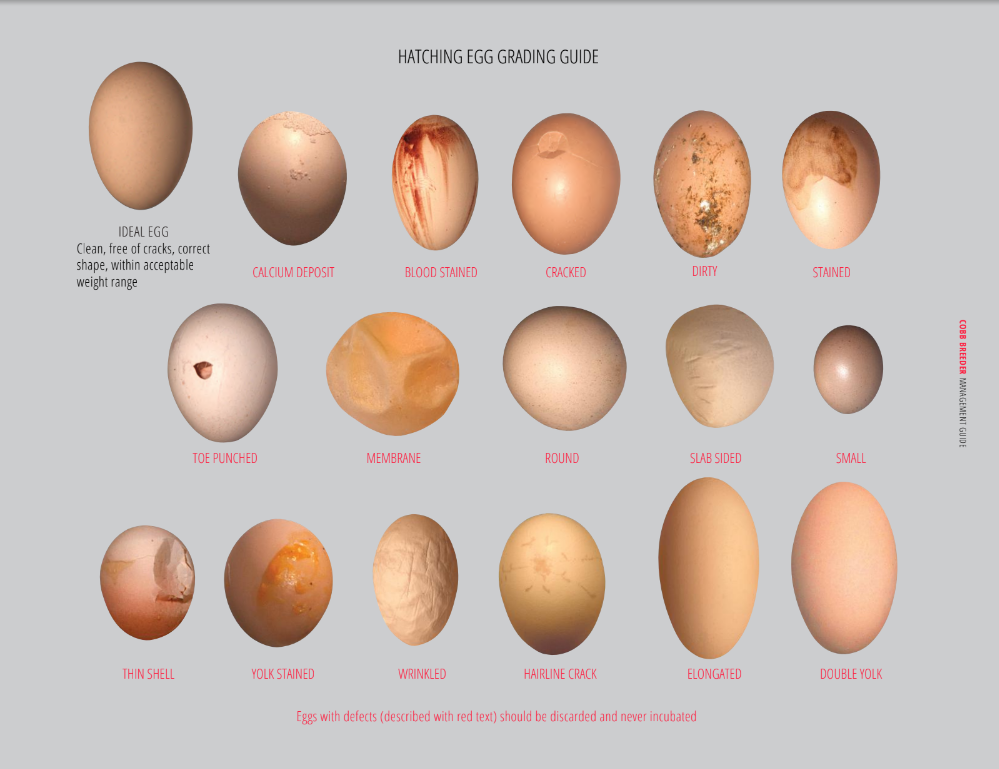

Egg Grading

Egg grading should be done with care to prevent mechanical damage to hatching eggs. Remove and discard eggs that are unsuitable for hatching including:

- Dirty or stained as defined by company policy

- Cracked

- Small - depending on hatchery policy

- Very large or double yolk

- Poor shell quality

- Grossly misshapen

Eggshell Quality

Almost 50% of discarded eggs are due to shell quality issues. A pale brown or white color can be the first indication of poor eggshell quality for broiler breeders. In pale eggs, it is likely that cuticle deposition and calcium accumulation are decreasing or not complete which could be a result of nutrition and disease. In some cases, eggshell quality issues are due to premature oviposition. Shell thickness and strength are critical factors and should be monitored over the life of a flock. There are a variety of tests that can evaluate shell quality including breaking strength, shell weight and thickness. Shell weight and thickness can be readily measured on site. A sample of 30 eggs per flock is recommended. Use relatively clean floor eggs instead of nest eggs since floor eggs are likely to be discarded.