Cobb Breeder Management Guide: Feeding hens after transfer and in production

Learn more about feeding options and featheringPart of Series:

< Previous Article in Series Next Article in Series >

Editor's note: This article is an excerpt from the Cobb Breeder Management Guide and additional articles will follow. The Guide was designed to highlight critical factors that are most likely to influence flock performance. The management recommendations discussed were developed specifically for Cobb products. The recommendations are intended as a reference and supplement to your own flock management skills so that you can apply your knowledge and judgement to obtain consistently good results with the Cobb family of products. To read or download the complete Guide or to view Cobb's other management guides, click here.

Early and late morning feeding

There are 2 programs for feeding broiler breeders in production:

Program 1 (Early Morning Feeding):

This program is used by 80 to 90 % of producers worldwide. With this method, feed distribution is initiated in the dark a few minutes before the lights come on in the morning, or up to 1 hour after the lights turn on. This program is preferred with single hole mechanical nests or manual collections. These nest systems cannot accumulate large volumes of eggs and must be gathered 4 to 5 times per day. This program is used in good performing operations, with minimal mechanical issues in terms of feed distribution.

If the birds are being fed 1 hour after the lights are on, switch off the lights when feed distribution starts to keep the birds calm and to get the best feed and bird distribution over the length of the house. The chain feeding systems should make one complete round before lights are turned on.

Program 2 (Late Morning Feeding):

This is the preferred program when there are management issues such as feed distribution, eggshell quality, labor or high numbers of floor and slat eggs. Although this program is not as widely used, it is quite effective under certain conditions. Good environmental control is very important to prevent any heat stress – do not use this program during the hottest part of the year without good environmental conditions.

Feeding late morning or 7 to 8 hours after the lights turn on in dark out housing, is done by switching off the lights during feed distribution. The lights are switched on when the first loop of chain feeders has been filled.

Some key points to consider when deciding on a feeding program

Program 1:

- Reduces heat stress and metabolic issues when using early feeding in tropical regions, especially during hot summer months or when houses do not have optimal environmental conditions.

- The hens have a stronger appetite with shorter consumption time when temperatures are cooler in the morning.

- This program allows afternoon mating activity with fewer interruptions.

- Equipment malfunctions can be detected early in the morning providing more time during the day for repairs.

Program 2:

- Begin late morning feeding during rearing, so that birds are accustomed to the feeding time. Typically, during rearing, feeding time is slowly moved from 8 AM at 10 weeks to 11 AM at 16 weeks of age.

- Delaying feed delivery allows producers to measure dry bodyweight (bodyweight before daily feed consumption).

- For young flocks, 8 hours after the lights are turned on, more than 90 % of the daily production has already been laid in the nests. Thus, in the early morning hens will not leave the nests for feeding.

- Late morning feeding allows a later start time for farm personnel. When arriving in the morning, personnel can go straight to egg collection.

- With late feeding, personnel are more likely to be present if equipment malfunctions during feeding.

- Late morning feeding is easier with community nest systems that allow 7 to 8 hours of egg production to accumulate on the central egg belt (50cm wide).

Bodyweight increase from onset of lay to peak production

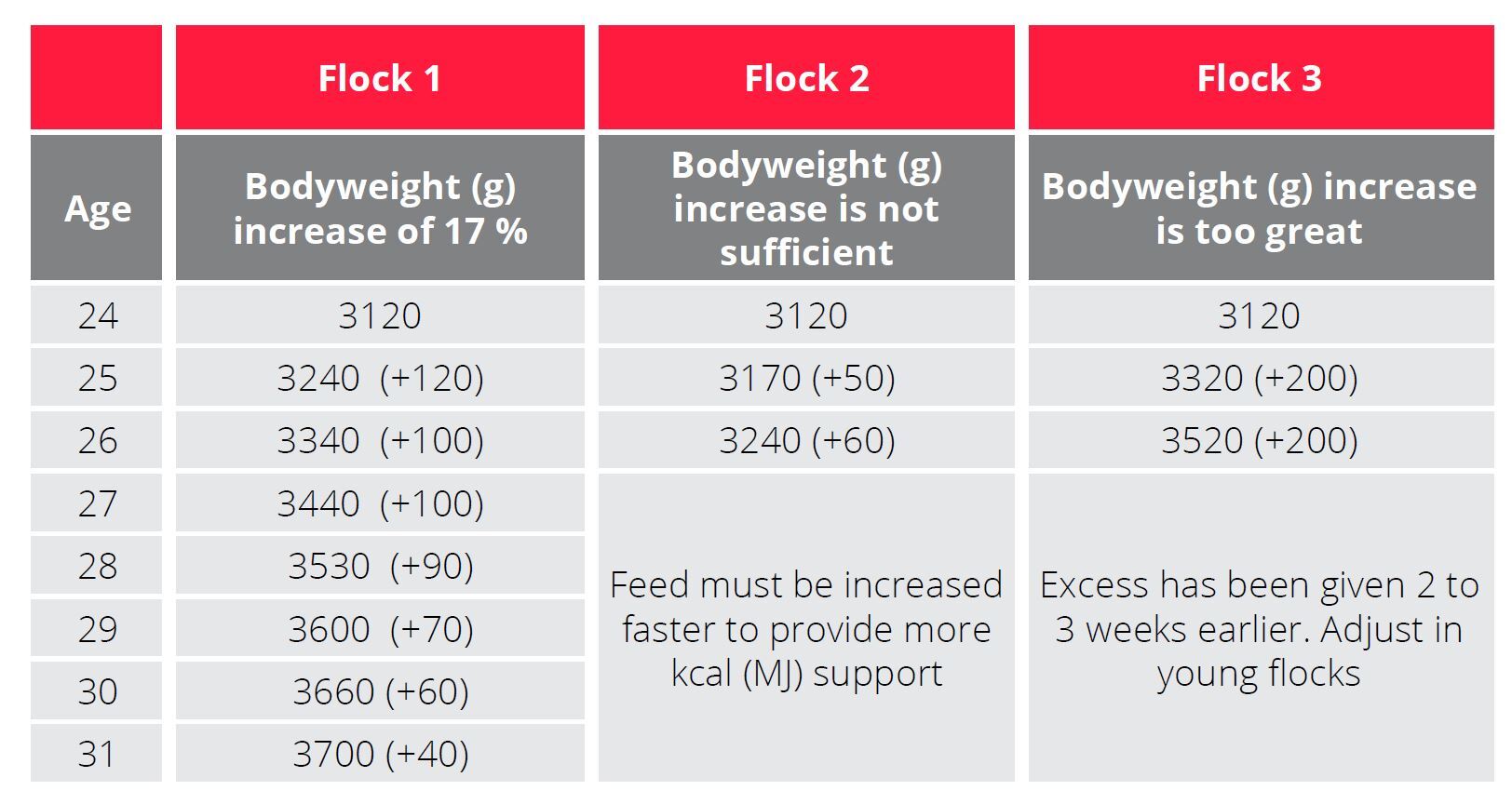

Monitoring bodyweight increases from onset to peak of production is a good indicator of feeding program management, because it provides forecasting of peak production and post peak production persistency. Peak production is determined by uniformity, bodyweight and feeding program in the rearing period. A good benchmark is to measure the weight gain of females from the onset of lay to peak egg production. Onset of lay being defined between 0.5 and 3.0 % weekly production. A bodyweight increase of 13 to 15 % is used when the bodyweight of the females is on standard and up to 5 % over or under the standard bodyweight. If the production in the first week surpasses 3 %, feed amounts can be based on the average bodyweight from the week before to perform the calculation.

Analysis of 3 flock scenarios:

In the table above, the most important data to manage flock performance are age, bodyweight, feed amount and percentage of production along with the timing of the first light increase. The standards are only a guide and use the Cobb 500 Fast Feather in closed housing as an example. A poultry technician can forecast based on the onset of production what the bodyweight should be at peak production and with the addition of a further 500 to 600 g (1.1 to 1.3 lb) the forecast bodyweight of the females at 65 weeks. This data could be used by the poultry technician to forecast the standard bodyweight profile for each flock over the production period. Optimum weighing programs include weights of females and males through 35 weeks of age, and then every 2 weeks from 35 to 50 weeks of age, and then every 4 weeks through the end of the flock.

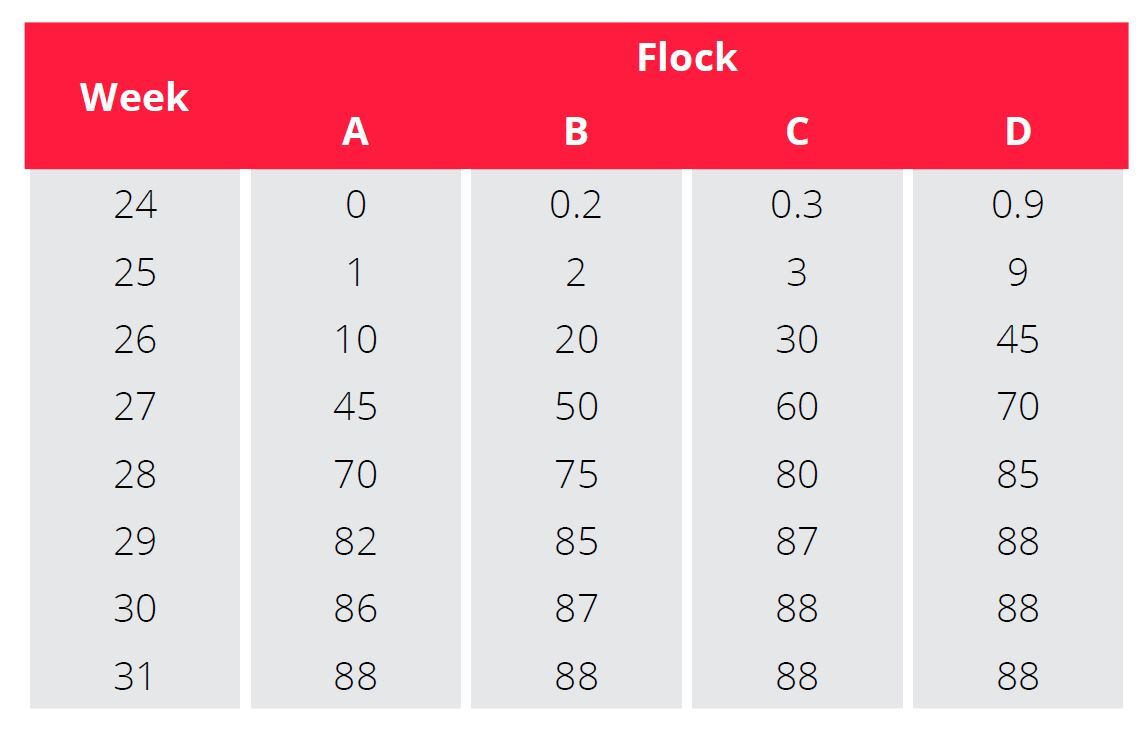

Production increase to peak production

Production increases over the first 3 weeks are a good indicator of peak production and persistency. The table (above) gives an example of 4 high performing flocks that are sexually synchronized and with peaks of 88 %. The table demonstrates production increases that are required for good peak production. Flocks with an average start at 1 to 3 % weekly production should increase production by 10 times the from the 1st to the 2nd week and double production from the 2nd to the 3rd week. This will indicate good sexual uniformity in flocks. In the table (above) Flock D resembles Flock A but Flock D starts production 1 week earlier. In general, by 28 weeks, all flocks should be above 80 % weekly production performance.

Post peak feeding – feed reduction

Broiler breeder hens are predisposed to become over weight and over fleshed, which could affect persistency of lay and fertility. Being over weight could potentially result in an increase in floor eggs due to difficulty in accessing the nest boxes. Peak production is the point at which the average percentage of production for the past 5 days begins to decrease. Reduction in the daily feed amount is important to maintain hen performance.

The following are 2 scenarios often encountered in the field and examples of solutions:

Over feeding at peak:

Decrease feed by 5 g post peak over 2 weeks. Then, decrease 1 g per week through 40 weeks. Finally, decrease 1 g per week every 4 weeks until the cumulative drop in feed is 7 to 10 %. (5 g per week = 1.10 lb per 100 hens per week; 1 g per week = 0.22 lb per 100 hens per week)

Correct feeding in peak:

Maintain peak feed for 2 to 3 weeks and decrease slowly with maximum of 1 g per week until total drop in feed is 5 to 7 %. More feed decreases are possible based on your local conditions including flocks going from winter to summer periods and depending on the energy specifications of the Breeder 2 feeds. (1 g per week = 0.22 lb per 100 hens per week).

Periodic handling of the hens, along with weighing, is necessary to determine subtle changes in body composition, condition and fat reserves of the hens. Additional items to consider when determining the feed reduction schedule:

- Cleanup time: A feed cleanup time of 1.5 hours for crumble feed and up to 3 hours for mash feed is considered normal. A flock that consumes the daily ration in less time may not be receiving the nutrients needed and may be hungry. Early feed withdrawal post peak could adversely affect production. Cleanup times of 3.5 to 4.0 hours will result in over weight birds, poor uniformity and excess feed amounts in peak production. Extended cleanup time can also lead to selective eating - birds selecting coarse particles and leaving the fine particles. This will cause a loss of uniformity and performance (egg numbers and female fertility). Furthermore, selective eating can reduce vitamin and mineral intake as these may be part of the fine feed materials. A faster peak feed withdrawal may be considered.

- Egg Mass: Egg weight and bodyweight are directly correlated. A higher bodyweight will normally result in a higher egg weight. Introducing Breeder 2 feed when egg weight is at 60 g for fast feather and 62 g for slow feather females can be an efficient way to control bodyweight and egg weight.

- Breeder 2 feed should always have the same or somewhat higher energy level as Breeder 1. Energy intake allows the females to produce and maintain production of eggs.

Hen feathering during production

Feather quality and cover of the hens in production is a very important indicator of production persistence and high fertility. The following are some of the primary reasons for rapid feather loss in breeder hens:

- Feathering issues in rearing due to management or low essential amino acid profiles in the pullet grower feed.

- Insufficient feeder space between 20 and 27 weeks when feed cleanup time is very fast.

- Feed distribution with lights on, resulting in overcrowding in parts of the house such as around distribution hoppers. This could also result in thigh scratches from females.

- Feed distributing with lights on results in hens running along feed tracks, inducing stress and internal lay or egg peritonitis.

- Low conditioning and fat reserves at photo stimulation. These females can show more feather wear as early as during peak production.

- Tight feed restriction grill (<45 mm or 3/4 in) will affect the heavier females after 40 weeks. These females will have trouble consuming enough feed leading to a drop in production and even molting. Their heads may experience feather loss and swelling because of the tight grill. This swelling should not be confused with swollen head syndrome or pneumo-virus.

- Over mating by males.

- Any feed passage, flushing or diarrhea reducing the absorption of nutrients.

- Chronic enteritis in the duodenum.