Cobb Breeder Management Guide: Managing microbial contamination and water sanitation

Learn more about water contamination levels and sanitation practicesPart of Series:

< Previous Article in Series Next Article in Series >

Editor's note: This article is an excerpt from the Cobb Breeder Management Guide and additional articles will follow. The Guide was designed to highlight critical factors that are most likely to influence flock performance. The management recommendations discussed were developed specifically for Cobb products. The recommendations are intended as a reference and supplement to your own flock management skills so that you can apply your knowledge and judgement to obtain consistently good results with the Cobb family of products. To read or download the complete Guide or to view Cobb's other management guides, click here.

Microbial contamination

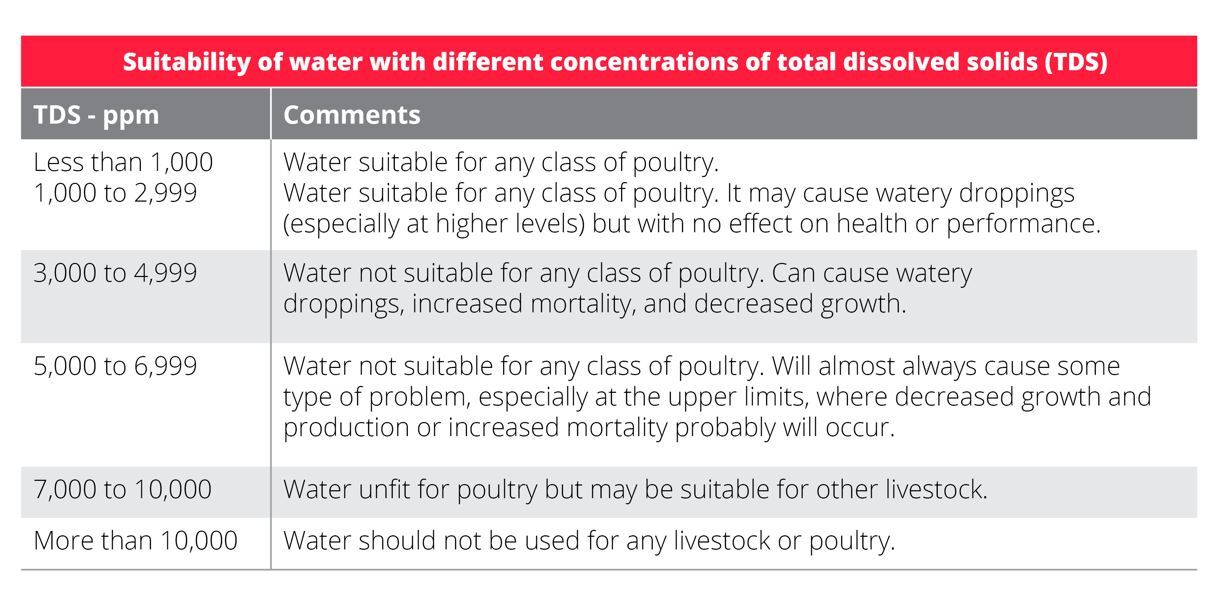

Chronically poor performance may indicate contaminated water and requires immediate testing. When testing water, evaluating the total coliform bacterial count is important, as high levels can cause disease. Assessing the total bacteria with a plate count will reflect the effectiveness of the water sanitation program. Microbial contamination can be introduced from the original water source and at any point in the water delivery system. If an effective water sanitation program is not in place, growth of bacteria will readily occur. Water storage tanks are common to ensure there is an adequate water supply during peak usage. Treat the water before pouring into the tank to prevent microbial contamination and growth.

Test the water if there is (are)

- a noticeable change in color, odor or taste

- flooding that has occurred near the well

- a person or animal that becomes sick from waterborne disease on the premises

- maintenance on the water supply system

- flocks that have persistently poor performance

- a major loss of flow or pressure in water system

Total dissolved solids

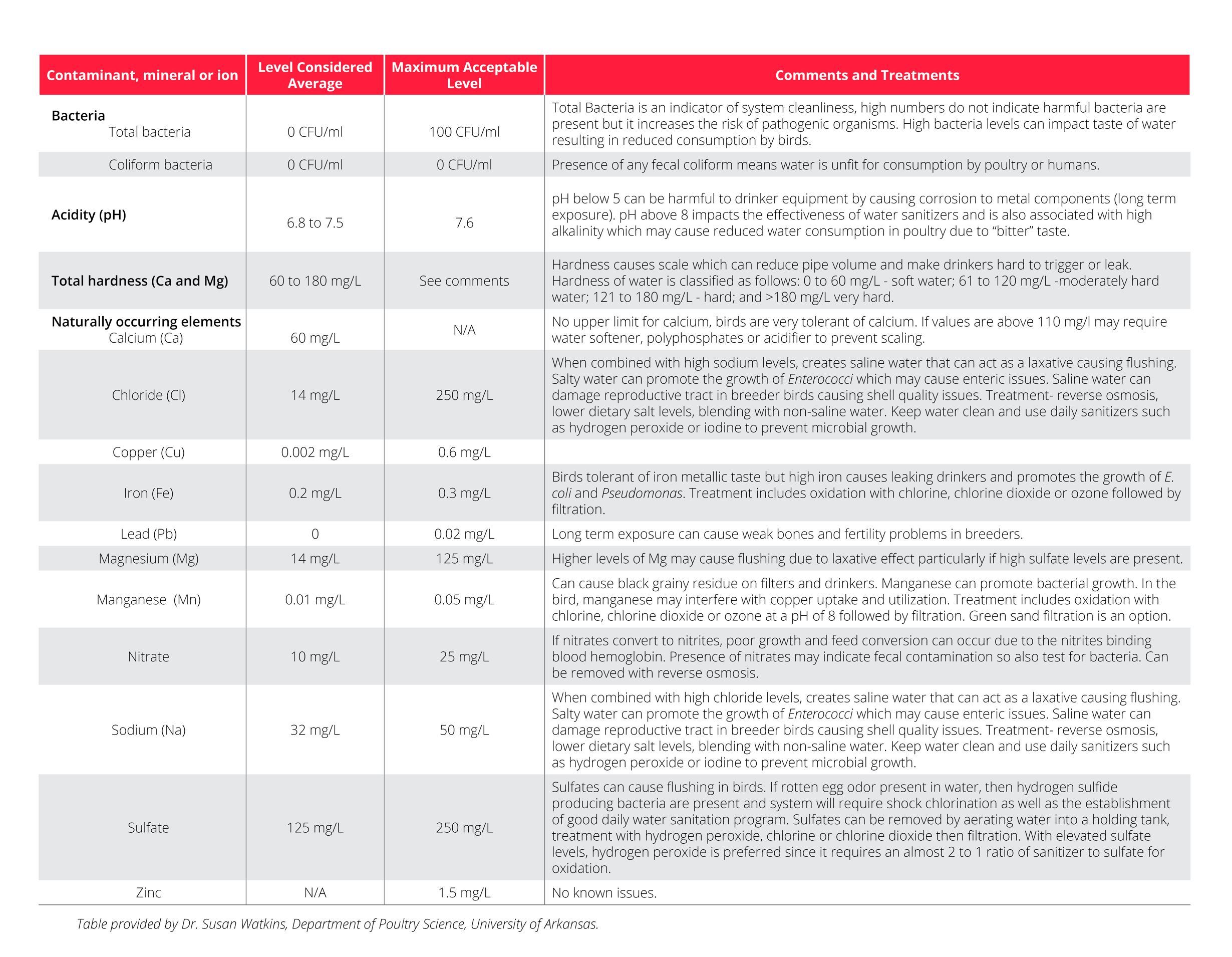

Measurement of total dissolved solids (TDS), or salinity, indicates levels of inorganic ions dissolved in water. Calcium, magnesium and sodium salts are the primary components that contribute to TDS. High levels of TDS are the most commonly found contaminants responsible for causing harmful effects in poultry production (as shown in the comments section in the table on the right.) The following table provides guidelines for the suitability for poultry water with different concentrations of total dissolved solids (TDS), which are the total concentration of all dissolved elements in the water.

Drinking system cleanout between flocks

- Determine the capacity of the drinking system.

- Drain drinking system and vaccination (doser) tanks.

- Where possible, remove vaccination (doser) tank and scrub it clean. If using a gravity fed header tank, drain and clean.

- Prepare the cleaning solution to the manufacturer’s recommendation. Make sure protective clothing and eyewear are worn when using chemicals.

- Introduce the cleaning solution into the water system.

- Turn on the tap at the end of the drinking line and let the water run through until the cleaning solution appears, then close the end tap.

- Raise each drinker line.

- Allow the solution to fill the drinking system.

- Let the cleaning solution stand for at least 12 hours.

- After draining the system, flush the system thoroughly to remove biofilm and cleaning chemical.

Water sanitation and system cleanout

A regular water sanitation and water line cleaning program can provide protection against microbial contamination and the buildup of slimy biofilms in water lines. While biofilms may not be an immediate source of problems to birds, once established in water lines, biofilms provide protection for bacteria and viruses from disinfectants. They can also trap organic material, a food source for microorganisms.

The use of various poultry products in water lines (ex: vitamins, electrolytes, organic acid, vaccines, vaccine stabilizers, antibiotics and probiotics) can all contribute to the growth of a biofilm. As a result, special attention to internal drinker line cleanliness should be initiated after the use of any of these products. Products containing hydrogen peroxide are proven effective at removing biofilms in water lines. Potassium peroxymonosulfate (also known as MPS, KMPS, potassium monopersulfate, and potassium caroate) are non-chlorine oxidizers that are also effective against biofilms.

Water testing

General water testing should be performed on a periodic basis but at least yearly. Samples should be collected at both the well house and at the end of a drinker line using a sterile container and analyzed at an accredited laboratory (see following page for specifications of mineral contents present in water samples). When taking the water sample, it is important not to contaminate the sample.

Water sampling technique

Sterilize the end of the tap or nipple by using an open flame for 10 seconds (always take extra precaution when using an open flame). Never use a chemical to sterilize a nipple as it may affect the sample. In lieu of an open flame, run the water for a few minutes before taking the sample.