Cobb Breeder Management Guide: Methods for grading breeders

Learn more about automatic and hand-based grading proceduresPart of Series:

< Previous Article in Series Next Article in Series >

Editor's note: This article is an excerpt from the Cobb Breeder Management Guide and additional articles will follow. The Guide was designed to highlight critical factors that are most likely to influence flock performance. The management recommendations discussed were developed specifically for Cobb products. The recommendations are intended as a reference and supplement to your own flock management skills so that you can apply your knowledge and judgement to obtain consistently good results with the Cobb family of products. To read or download the complete Guide or to view Cobb's other management guides, click here.

It is very important to have the flock at the correct weight and uniformity by 4 weeks with a maximum of 5 % above or below the standard. Correct weights and high uniformity at 4 weeks of age will prevent severe feed restrictions or increasing feed amounts during the maintenance period.

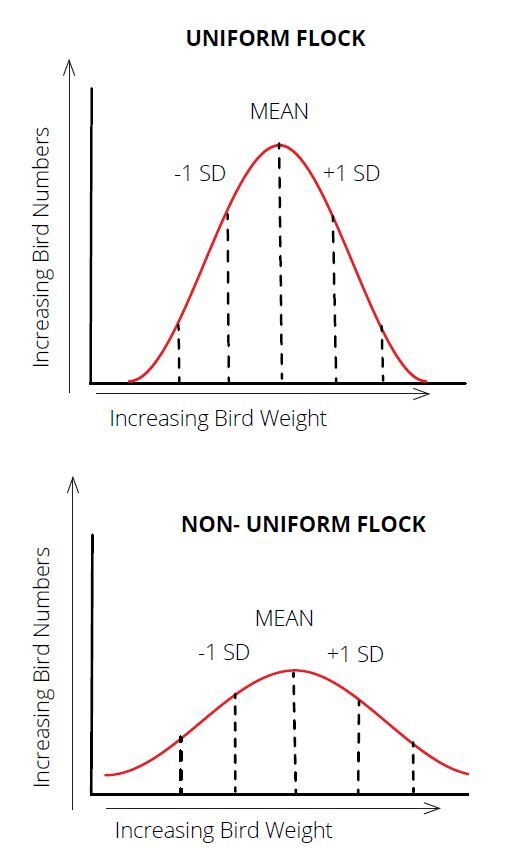

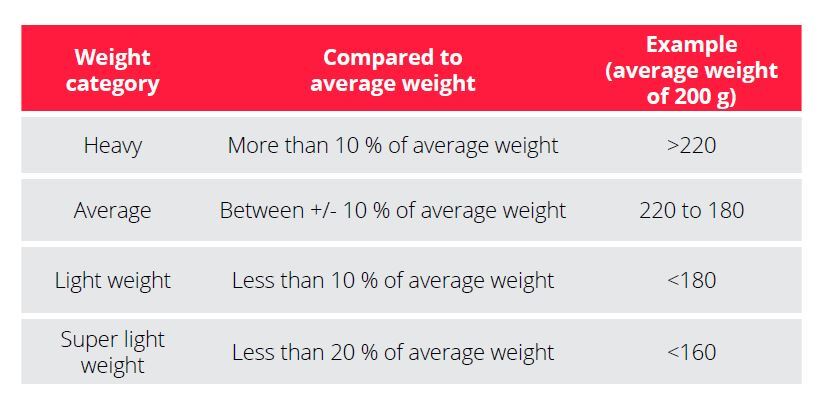

An important tool to improve uniformity is grading. Grading is the process of sorting individual birds into categories based on bodyweight (super light, light, average, heavy) so that birds within respective categories can be managed back to standard. Sorting birds into categories can be done after taking individual weights and calculating uniformity, CV and standard deviations.

Perform a 100 % weighing and grading when the flock is 7 to 14 days old. This allows the birds to be grouped by weights and feed consumption, which controls competition for feed from a very early age. The subsequent 100 % flock gradings should take place at 4, 8 and 12 weeks of age or when uniformity is below 65 %. Birds should be classified in heavy, medium and lightweight compared to the average weight. Do not delay grading ages or the advantage obtained in the first grading will be diminished.

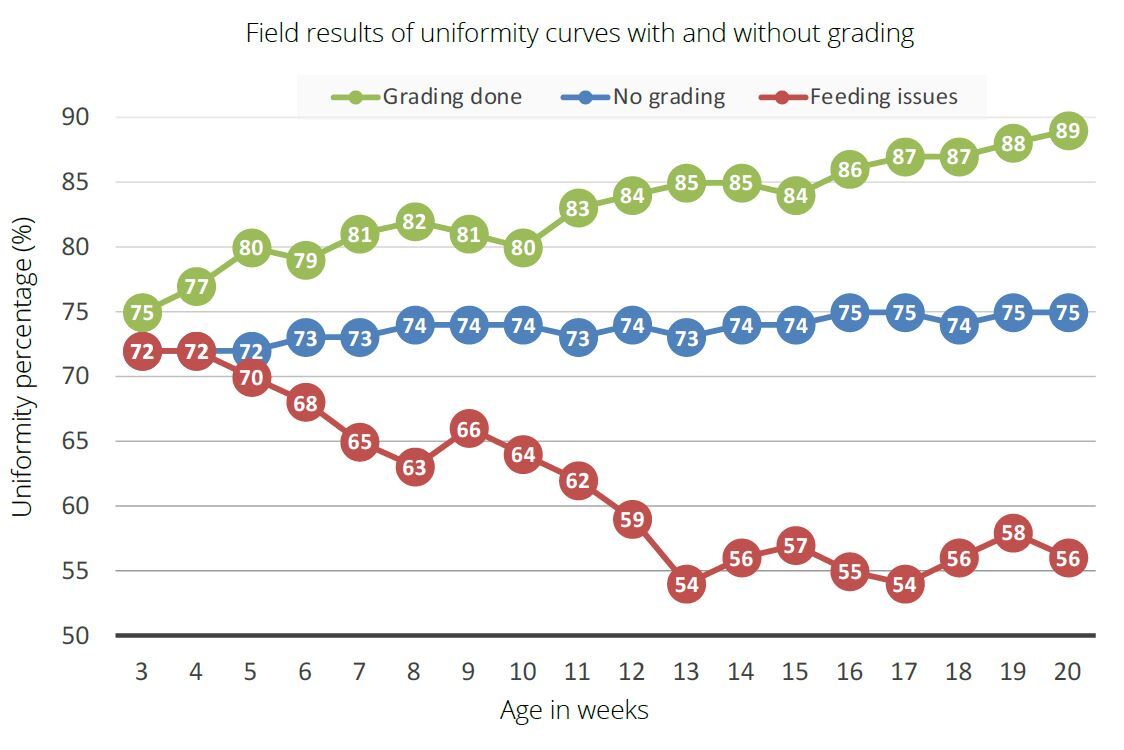

It may be helpful to evaluate the results of grading performed at an earlier age, for example, at 3, 7 and 11 weeks of age. It is clear that if gradings are performed early, it is possible to obtain and maintain uniformity equal to or greater than 80 %. In some regions, the cost of labor prohibits multiple gradings. In these markets, if only 1 grading can be done, the best age is between 21 and 28 days of age. Performing a grading at this age will provide more time to correct any uniformity issues.

Regardless of the number of gradings done in rearing, it is very important to have the basic management criteria correct including: enough feeder space, fast feed distribution (in the dark), good bird distribution over the whole house, constant feed increases on a weekly basis and enough drinking water available with the correct water pressure. Males follow the same grading concept as females and, in general, should be 5 % higher in uniformity than the females. Males represent only 10 % of the flock but are responsible for 50 % of the offspring.

The average minimum uniformity in rearing should be above 70 % (± 10 % variation of the mean) from 3 to 20 weeks. This uniformity should be maintained fairly constant or should increase towards the end of the rearing period. Uniformity below 70 % indicates there are feed intake issues and the flock is not uniform. Being present at feeding is one of the most important times of the day. It is then that errors can be identified, and immediate adjustments can be made so that the flock continues to grow uniformly.

Automatic grading machines

There are a range of models on the market. A larger model is available and is suitable for companies with flocks of more than 300,000. This machine can vaccinate pullets but is not easy to move. In contrast, other smaller models are readily mobile and constructed of stainless steel for easy cleaning. These smaller models are limited to grading chicks and birds up to 20 weeks of age. In general, grading with machines is recommended for 2 gradings at 3 to 4 and 10 to 12 weeks of age, to maintain average uniformity in rearing well above 75%.

Advantages of automatic grading include:

- Can be faster than hand grading and typically requires less personnel

- Capacity based on models can grade from 1500 to 3000 birds per hour

- Sorts birds with exact weight ranges and no mistakes with counting birds that are sorted into groups (a main issue of hand grading)

If more information is needed, contact your Cobb representative to get information on the latest developments.

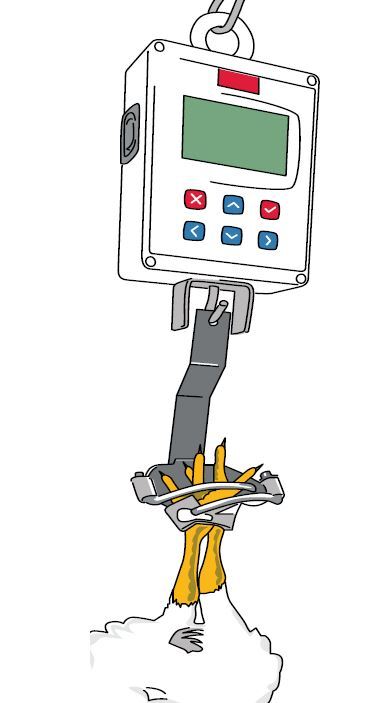

Weighing and grading by hand

Digital hanging scales are available for grading by hand. Many digital scales can record and store weights to the nearest gram, calculate an average weight, and display histograms of the weight distributions.

The cutoff values for sorting the flock into groups can be programed to make weighing and sorting faster and easier. Finally, digital scales can also count the number of birds that were weighed and the final number of birds in each group can be displayed on the scale. It is important to note that, if the number of birds in each group is not accurate, then the feed allocations cannot be accurately calculated.

Grading procedure

Cobb recommends sorting birds into 3 groups: heavy, average, and light. Depending on uniformity and CV, a 4th group (super light) can be used.

Some houses have fixed pens or partitions, and in these houses, at least one pen should be left empty at placement for the sorting process. It is important to remember that if birds are moved to an empty pen during sorting to transfer some of the litter from the used pen to the unused pen to facilitate the cycling of the coccidia vaccine. If fixed pen or partitions are being used, the size of the pen should be used to calculate the maximum number of birds per pen based on floor, feeder and drinker space. Likewise, for adjustable pens and partitions, adjust the size of these areas based on floor, feeder, and drinker space required for each bird. If floor, drinker and feeder space is not adjusted to meet bird requirements within the pens, sorting birds can actually cause more problems!

Stocking density is important for welfare and uniformity reasons. If pen density levels are too high, uniformity can diminish. In some settings where labor is readily available, multiple small pens can be prepared. In this case, it is recommended that the number of birds per pen not exceed 1,000 birds with 600 to 800 birds per pen being ideal. In houses with 8,000 to 10,000 birds, small pens are not practical. Each pen should have an independent feeding system. If this is not possible, supplementary feeders can be used to adjust the feed allocations to each pen.

Grading and sorting process

- Prior to grading, a portion the flock (3 to 5 %) should be weighed. (It is recommended to collect a sample weight even if automatic scales are being used). Determine the average, standard deviation and CV or uniformity (further reference). There are two ways to determine the sorting weights:

- Use standard deviation as a cutoff. In this way, 68 % of the flock will be placed in the average category, and the light group (- 1 SD) will contain 16 % of the flock. The remaining 16 % of the flock will be + 1 SD and belong to the heavy group. For example, if there are 3,000 birds in a flock, 2000 would be average weight, while 500 would be light and 500 would be heavy. This approach works with all flocks but can be very effective for flocks with poor uniformity. Normally, under good management conditions and without gradings the uniformity will be around 70 to 72 %. Therefore, working with +/- 1 SD will be more natural for flock uniformity.

- Using a plus or minus 10 % calculation can also be used to grade and sort birds into groups according to the table (below).

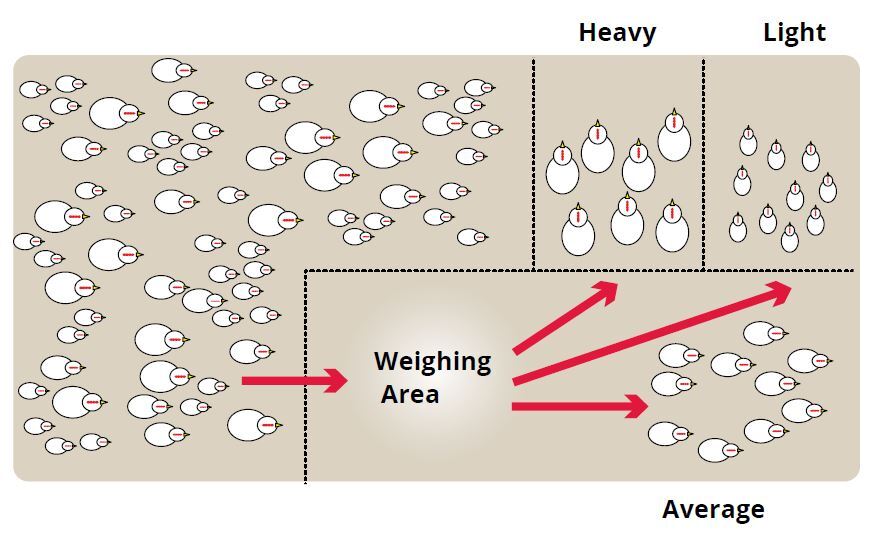

- After the cutoff value has been calculated. Each bird should be weighed and sorted into the correct group (see diagram below). Digital scales can be used to program cutoff values for each group to make sorting faster and easier. The scales can also count the number of birds being sorted into each group.

- If hand weighing, re-weigh a sample of birds from each pen after sorting. Calculate average bodyweight, the variation (CV), and uniformity. Use this data to determine adjustments to feed allocations to bring the bodyweight back to the target. It is also a good practice to recount the birds per pen to be sure the correct number of birds get the correct feed allocation after grading. Wrong bird numbers per pen are considered one of the major errors seen with hand weighing.

Flock management after grading

Calculate feed allocations for each group based on number of birds and average bodyweight to bring bodyweight back on target (see bodyweight correction curves).

- Feed allocations should never be reduced!

- Any increases in feed amounts should be done conservatively. Keep in mind, that it may not be necessary to increase feed amounts as competition for feed will be reduced after sorting the flock.

- Continue monitoring bodyweights with weekly weighing.

Competition for feed is always present throughout the birds’ lives. As noted, weight grading at an early age enhances management of feed consumption by separating the flock into specific weight categories and feeding back to standard bodyweight. Within sorted groups, it is common to see uniformity above 90 % after grading. However, soon after grading, expect uniformity to decline to a typical level of 70 to 72 % as pecking (social) order and feed competition become re-established within sorted pens.

If after the first sorting, uniformity of the population across all pens drops to 65 % or below, an additional sorting and grading should be performed. In addition, determine why the uniformity continues to decrease. Normally feed management issues are involved. A crop check can also help determine poor uniformity causes. Some producers perform multiple grading and sortings during rearing as part of a standard protocol. For subsequent grading and sortings, follow the same protocol as described.