Cobb Breeder Management Guide: Ventilation management

Learn more about circulation fans and minimum ventilationPart of Series:

< Previous Article in Series Next Article in Series >

Editor's note: This article is an excerpt from the Cobb Breeder Management Guide and additional articles will follow. The Guide was designed to highlight critical factors that are most likely to influence flock performance. The management recommendations discussed were developed specifically for Cobb products. The recommendations are intended as a reference and supplement to your own flock management skills so that you can apply your knowledge and judgement to obtain consistently good results with the Cobb family of products. To read or download the complete Guide or to view Cobb's other management guides, click here.

To achieve optimal flock performance the ventilation system must provide optimal conditions in both cold and hot conditions. In cold weather and during brooding, the system must control moisture and air quality while also ensuring uniform and stable temperatures. During hot weather the ventilation system must provide sufficient cooling capacity to keep the birds as comfortable as possible. However, the house environment is a dynamic environment with fluctuating temperatures, air quality and humidity levels which requires constant monitoring and adjustments to ventilation.

Managing poultry house humidity and litter moisture are two of the greatest challenges a producer may face. High house humidity conditions during hot weather produce two challenges; it reduces the birds thermoregulation ability through evaporative cooling and makes the management of litter moisture conditions challenging.

During cold weather the challenge is to condition the incoming cold air before it circulates to bird level. Mixing the incoming cold air with the heat trapped at ceiling level due to natural stratification along with circulation fans are the two most important concepts the producer needs to master for the successful management of litter moisture.

Circulation Fan Installation Options

The primary function of a circulation fan system is to disperse the natural heat stratification in the house. It is not unusual to see up to 5 °C (25 °F) difference between the ceiling and floor level. These systems are designed to mix the air from the floor to ceiling by producing air movement at floor level of between 0.25 to 0.76 m/s (50 to 150 fpm), removing moisture from the litter. There are many different designs and setups for circulation fans.

Circulation fan requirements:

- Capacity: approximately 10 to 20 % house volume.

- Typical circulation fan size and capacity: 450 mm (18 in) fans with capacity of 70 m3/min (2500 cfm).

- In high ceilings and new tunnel ventilated houses, larger 600 mm (24 in) circulation fans with a capacity of 140 m3/min (5000 cfm) are being used.

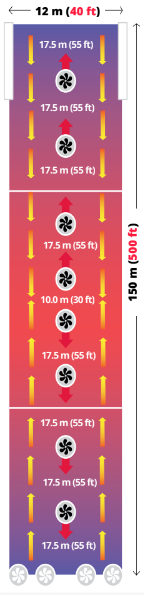

Example calculation of how many fans are needed:

12 m (40 ft) wide house; 150 m (500 ft) length; 3 m (9.5 ft) average height

12 m (40 ft) x 150 m (500 ft) x 3 m (9.5 ft) = 5472 m3 (190,000 ft3)

5472 m3 (190,000 ft3) × 10 % = 547 m3/min (19,000 cfm) stir fan capacity

547 m3/min (19,000 cfm) ÷ 70 m3/min (2,500 cfm) = 7.6 or 8 fans

The large red arrows indicate high velocity movement at ceiling level, while the smaller yellow arrows indicate the low velocity return created at floor level. Increasing circulation fan capacity will increase the “return” air movement at floor level. As long as the return is warm, moving warm air does not constitute as a draft! The more circulation capacity, the dryer the litter.

Minimum Ventilation

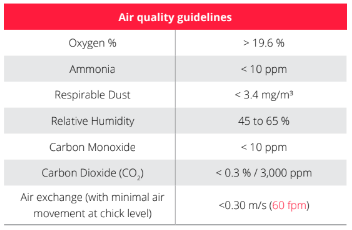

Minimum ventilation systems are designed to manage moisture and air quality using fans on a cycle timer. This system is independent of the temperature control and the minimum air exchange is linked to the amount of moisture added to the house by the birds, as well as the drinking, heating, and ventilation systems. Under most conditions, maintaining good moisture control should ensure carbon dioxide and ammonia levels are kept below 3000 and 10 ppm, respectively.

High levels ammonia are always linked to high house humidity and litter moisture. High levels of ammonia can increase the birds susceptibility to disease and potentially creating a welfare issue. Additionally, birds raised in wet litter conditions can have a rapid decline in foot health and may lead to pododermatitis.

There are 3 key functions of minimum ventilation:

- Moisture and humidity control

- Provide oxygen to meet the bird's metabolic demand

- Maintenance of good litter conditions

*The maximum level of CO2 allowed at any time in the chicken house is 3,000 ppm. If the house environment exceeds 3,000 ppm of CO2 or less than 19.6 % O2 then the ventilation rate must be increased.

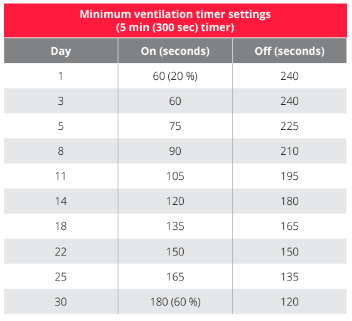

5-minute timer cycle to control minimum ventilation

- The timer fans should provide an air exchange capability of approximately 12.5 % or a capacity of 0.3 to 0.61 m3/min per m2 of floor area (1 to 2 cfm per 1 ft2 of floor area).

- Always match fan capacity as close to requirement as possible.

- At placement, fans should be cycled for approximately 30 to 60 seconds to ensure adequate mixing of cold incoming and warm internal air (see table right).

- A 5-minute (300-second) on/off cycle is preferred for minimum ventilation. The cycle should never exceed 10 minutes.

- Any time the air quality begins to deteriorate, the ON time must be increased - but the total cycle time always remains constant.

- Humidity should be maintained below 60 to 65 % where possible.

- Increases in ON times should be made in small increments – 10 to 15 seconds and monitored for 24 hours.

- Correct operation of the perimeter inlets is vital in achieving good air distribution and moisture control.

- The inlet capacity should match the fan capacity at the required working pressure based on the width of the house.