Factors affecting chick comfort and liveability from hatcher to brooding house

Pedigree, great grandparent and grandparent broiler breeding stock need to have excellent health status to minimise the risk of vertical transmission of pathogens. They must be kept under very high biosecurity conditions, which are most effective if birds are in locations remote from commercial broilers or layers, and other avian species. This can often result in situations where day-old chicks supplied to breeding stock customers may need to be transported over long distances.

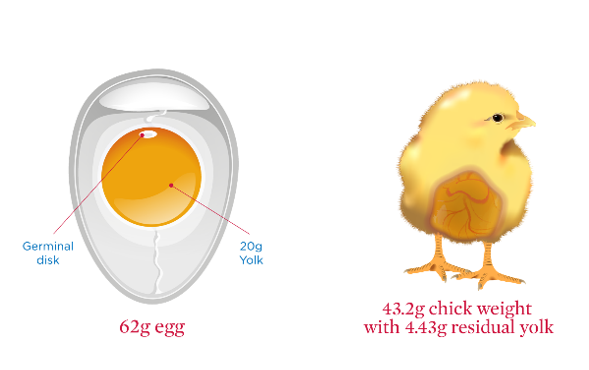

When considering journey times, poultry have a major advantage over mammalian livestock, in that when chicks hatch they contain a significant reservoir of residual yolk which is directly connected to the small intestine by the yolk stalk. At the time of lay, the yolk of a broiler egg will be 30-33 % of the total egg weight – e.g. 20g of yolk in a 62g egg. In a properly incubated batch of eggs, (incubated at an embryo temperature of 100F (37.8oC), with an 18 day weight loss of 11% and pulled at a chick yield of 68%,) the residual yolk will weigh between 4 and 5g - somewhere between 9.5% and 12% of the fresh chick body weight. The reserve of nutrients and water in the residual yolk is sufficient to keep the chicks in good condition for 3 days.

Most countries impose regulations which define the duration of and environmental conditions acceptable for different types of livestock in transit. Until recently, these regulations all reflected the unique advantages of transporting chicks while the residual yolk is still present and permitted longer journey times for them, up to 72 hours after dispatch.

Recently, there has been a lot of discussion concerning how the interval between when the chicks are removed from the hatcher and when they arrive on the farm at their journey’s end should be handled. Thinking has undoubtedly been affected by the recent development of systems that either allow the chicks to hatch on farm or provide feed and water in the hatcher so that it can immediately be available to individual chicks as they hatch. Both have the advantage of shortening the total cycle time from eggs set to broiler processing, simply because the chicks have food available when otherwise they would not.

This article summarises some of the internal trials carried out by Aviagen to check whether our transport targets and protocols are still appropriate or whether they need to be changed. All were scrutinised and approved by directors responsible for animal welfare and ethics.

Utilisation of the Residual Yolk in Modern and 1972 lines

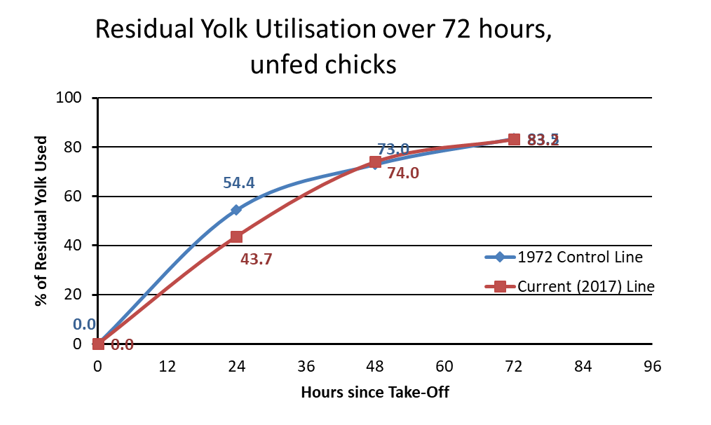

One of the arguments for shortening permitted holding and journey times, is based on the assumption that the modern broiler embryo produces more heat, and because of its’ “higher metabolic rate” is likely to utilise the residual yolk after hatch more quickly than in the past. (While an intuitively attractive theory, the published data do not support it.)

Aviagen holds genetic control lines, which were separated from their respective pedigree populations in 1972. A trial in 2017 compared genetic control lines with their current equivalents. The rate at which the residual yolk was depleted was very similar in both the control lines and their modern counterparts. Held for 72 hours post chick take off, the lines tested used just over 80% of the residual yolk present at hatch. Figure 2 shows that the rate of utilisation was slightly faster in the 1972 control line than its modern equivalent to 24 hours, and equal at 48 and 72 hours.

Holding Temperature, Body Temperature, Residual Yolk Utilisation and Liveability

When chicks hatch, they do not have full control of their body temperature; it changes with the temperature of the surrounding air. However, chicks do generate metabolic heat, and are able to modify their behaviour if too cold, by huddling together or if too hot by maximising distances between individuals and panting (Figure 3).

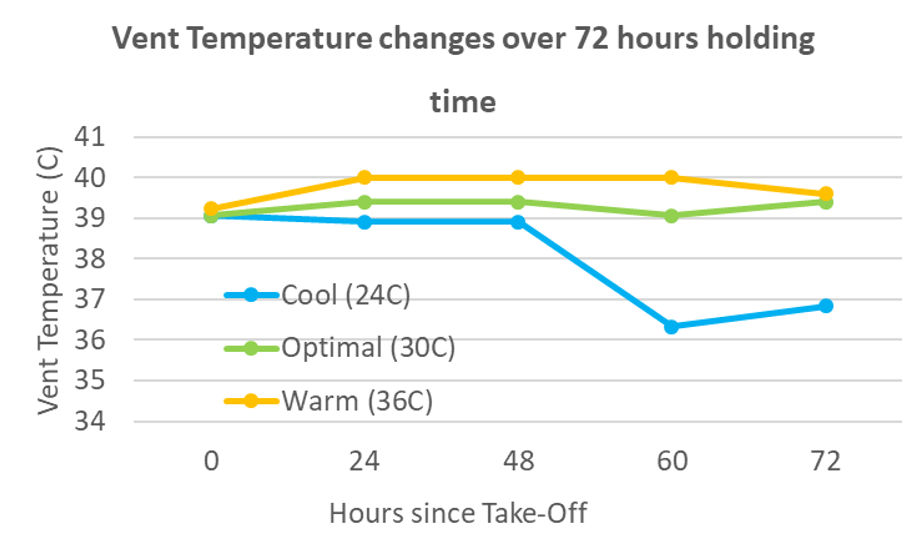

Day old chick body temperature can easily, safely and accurately be measured using a Braun ThermoScan paediatric thermometer at the vent. When small groups of unfed chicks sit in boxes for transport, the vent temperature target of 39.4-40.6oC (103-105oF) will usually be achieved if the in-box temperature is around 30oC (86oF). In internal trials where the environmental temperature in the boxes was lowered or raised by 6oC (11oF), to 24oC (75oF) or 36oC (97oF) the chicks’ body temperatures also changed. Chicks in the hotter environment gained 0.4oC (0.7oF ) and chicks in the colder environment lost 0.4oC (0.7oF) body temperature over the first 24 hours. However, after 48 hours holding, the chicks’ body temperature in the warm and optimal environments remained stable, whereas the chicks in the cooler environment lost a further 3.1oC (5.6oF). The change in vent temperature over time, averaged over three trials, is shown in Figure 4.

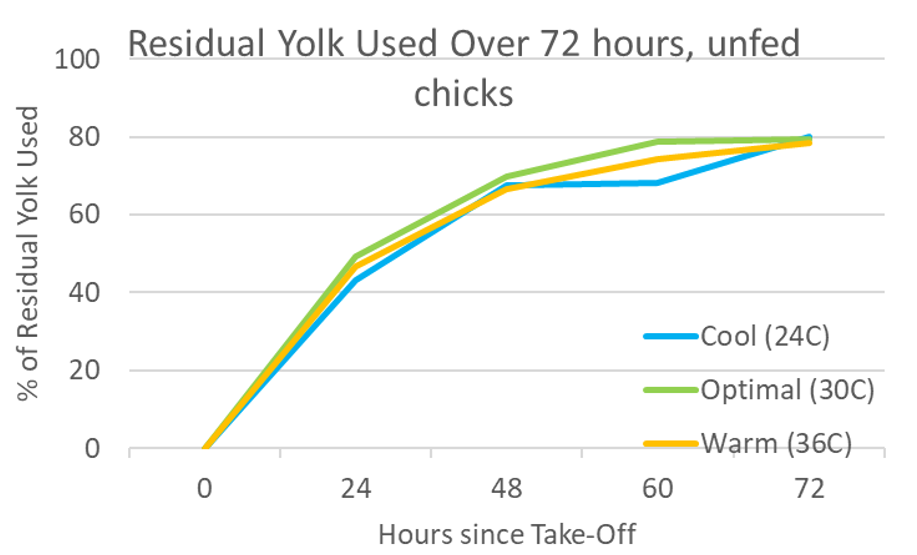

Surprisingly, holding temperature did not have much effect on how fast the residual yolk was used up. However, a small number of individuals in the cool treatment apparently stopped mobilising yolk after 48 hours holding. This made the 60-hour utilisation appear less than that of controls in an optimal environment. Reports in the literature suggest that temperature extremes post hatch can delay or stop residual yolk utilisation. Figure 5 shows the yolk utilisation over 72 hours averaged over three trials.

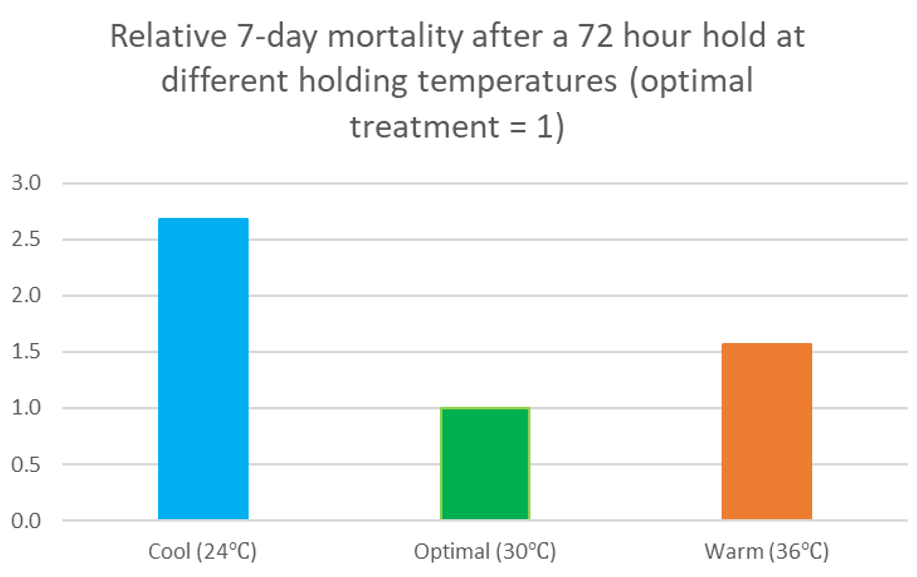

Liveability to 7 days was different in each trial, but the treatment effects were very similar. In Figure 6 below, mortality rates for the control treatment in each trial were treated as a unit baseline, and the difference due to adverse temperature calculated as a relative increase. Populations kept in the cool environment lost 2.7 times as many chicks as those kept comfortable. The warm environment also increased losses, but the increase was only 1.5 times. The relative 7 day mortality levels are shown in Figure 5.

Although transport that is too cool is harder on the chicks than transport that is too hot, chilling is also much less likely to happen. Chicks produce metabolic heat, and sitting together in boxes the goal is usually to stop too much heat from building up. However, the trials gave a very clear message that in endeavouring to avoid overheating, it is vitally important not to go too far.

Hatchling Supplements and Early Feeding

Regulations covering transport times and conditions for health certificates for day old chicks take into account that the residual yolk will supply food and water to support them post hatch.

It is now common practice, and sometimes a legal requirement, to offer broiler parent and grandparent chicks a hydration supplement at the hatchery. Several companies supply them, in a gel form with about 5% by weight taken up with gelling agent and some sort of electrolyte, and the remainder water. Uptake of such products is variable – sometimes chicks consume the gel enthusiastically, other times they do not touch it for no obvious reason. Distributing the product evenly across a box of chicks can be difficult, and checks on crop fill suggest that after 6 hours 40-60% of the chicks will not have consumed any of the gel. In replicated trials, the first week mortality of chicks which have been offered hydration product is usually similar to that of chicks offered no supplement.

There is a risk specific to giving supplements at the hatchery before a long journey. Early tests conducted by Aviagen using a specialised hatchling supplement showed that although it improved 7-day weights after journeys of up to 40 hours, for longer journeys the chicks did not survive as well. More recent trials showed that after a 72 hour hold the liveability of chicks given a hydration product at the hatchery can be worse.

Allowing individual chicks access to feed and water immediately after they hatch is possible, either in specialised hatchers or when partially incubated eggs are transferred to the broiler house after 18 days. In both cases, the eggs are candled so that only eggs containing live embryos are transferred. The eggs are held in a setter tray, small end down, and when the chicks hatch they drop down and have immediate access to food and water. This type of system eliminates the usual holding period between chick emergence and the offer of food and water. Having had food available for a day or more longer, the final broiler weights at a standardised age are usually higher.

There are some potential problems with early feeding systems, even when hatching broilers. First, the feed and water must be put in place before the eggs are transferred, and is then held in that warm, humid environment until the chicks hatch. Feeders, drinkers, and water lines must be immaculately clean if bacterial or fungal growth is to be avoided. Secondly, individual chicks will not usually show any interest in feed for some hours after they hatch. It is therefore commonly suggested for systems where chicks are to be fed in the hatcher that they should be kept in the hatcher for several hours longer to make sure that even the last chicks to hatch have had time to find and consume feed. Thirdly, fed chicks have a much higher metabolic heat output than chicks, which have not yet eaten; 24 hours after feeding the heat output is roughly double that of unfed chicks. This is normal and is not an issue when it happens after hatching on farm, but chicks fed in the hatchery have to be transported, and the ventilation and cooling capacity of the trucks must be upgraded if chicks are to be fed in the hatchers.

For broiler breeders, early feeding is problematic. There are several reasons for this. Chicks are very much easier to vent sex, an essential part of breeding stock production, when their guts are empty. Chicks with full guts produce wet droppings, which make both chicks and boxes wet and dirty – cardboard boxes may collapse in transit. For long journeys it is likely that the liveability can decrease if the chicks are fed at hatch, and then left unfed throughout transit. This is because when chicks have not been fed, their digestive system is not activated and the residual yolk functions to keep them in what is effectively an extension of the embryonic stage. Once feed is given, the gut is activated producing stomach acid and digestive enzymes which can damage the gut if it is then allowed to become empty again. Finally, the additional heat output from each fed chick is also a concern, especially for chicks sent by air, because the extra cooling needed will not be available on planes.

Some reports on the benefits of early feeding have suggested that when feeding is delayed, the immune competence of the chicks will be impaired. To sense-check this hypothesis, it is possible to compare the performance of grandparent chicks placed by Aviagen on company run farms worldwide. All of them are supplied from great grandparent production bases in the UK and the USA. Performance data of the birds in lay shows that there is in fact no statistically or numerically significant relationship between journey time (and therefore the time elapsed between hatch and access to feed) and lifetime liveability or egg production.

Interestingly, the hatchability of fertile eggs and chick quality in these systems are usually good, often better than that of eggs from the same batch hatched conventionally. In both systems which offer early feeding, the effective stocking density of the chicks is very much lower than in a conventional hatcher. It is possible that at least some of the advantages attributed to giving early feed and water are due to improved environmental conditions at hatch.

Having re-examined the holding and journey times, environmental conditions and nutritional status of breeding stock during transport, it was reassuring to find that the rate of residual yolk utilisation remains unchanged. The target box temperatures in use also remain optimal, and we can deliver chicks after journeys of between 60 and 72 hours without detriment to 7-day mortality or to lifetime performance and without having to provide feed and water in the hatchery.