High-tech cameras focused on chicken breast defect detection

'Woody breast’ chicken meat accounts for $200 million premium yield lossSome research for poultry processing automation is more than meets the eye.

A multidisciplinary team of scientists at the Arkansas Agricultural Experiment Station are testing to see if hyperspectral images can be used to detect a chicken breast defect known as “woody breast” that costs the poultry industry millions of dollars annually and decreases customer satisfaction.

Dongyi Wang, assistant professor of biological and agricultural engineering, explains that hyperspectral imaging is a non-invasive sensing technique that combines a near-infrared sensor with a high-definition color camera to capture physical and chemical information.

“The current evaluation procedure is time-consuming and needs a sample tested through cumbersome laboratory tests,” Wang said.

Woody breast detection with a hyperspectral camera system would take just a few seconds with a computer instead of grading by hand.

“Woody breast detection by hand can be labor intensive,” said Casey Owens, the Novus International Professor of Poultry Science at the experiment station. “If hyperspectral imaging can be used in a poultry processing plant, that labor force could be diverted to another area.”

Owens said woody breast affects up to about 20 percent of chicken breast meat. Although it can be diverted for further processing, the loss in premium as a whole-muscle product accounts for a yield loss worth about $200 million annually in the United States, Wang said.

“Woody breast is still a safe product. It just can have a crunchy texture in some cases that is not appealing to customers, but it can be diverted for further processing into products like chicken nuggets, sausage, or chicken patties where the defect is not as noticeable,” Owens said.

Woody breast meat is harder to the touch because it has less water-holding capacity and less protein content, so the meat doesn’t retain marination as well as meat without the defect.

The woodiness is more common in larger birds of 8-9 pounds versus a 6-7-pound bird. Owens said one theory is that the fast-growing birds may be producing muscle faster than the blood vessels can support them, leading to muscle fiber damage and therefore increased collagen deposits.

Chaitanya Kumar Reddy Pallerla, a food science graduate student working on the project, said each image with a hyperspectral camera takes up about 1 gigabyte of data. The photo is processed by a computer and correlated with a texture map indicating hardness levels in the fillet created with Owens’ previous research. Once calibrated, the system would rely on the images alone to detect woody breast.

“What we’re trying to do is collect the spectral data, intensities that were reflected, and correlate them with texture properties,” Pallerla said. “These are rated with a texture analyzer initially, and if we find a correlation between this spectral information and the texture properties later, we do not need a texture analyzer. So, we can use this correlation and directly interpret the texture properties from the spectral properties.”

Although protein content, water holding capacity and texture properties are considered the best markers for woody breast detection, Pallerla said most researchers have not focused on those properties because of the level of irregularities in the sections of a chicken breast.

Wang said the hyperspectral camera, so far, has detected woody breast meat with about 84 percent accuracy. The goal is to accommodate high-speed sorting on a conveyor belt, or handheld portable devices, he added.

Pallerla said the research will help fine tune their current texture analysis map and decrease the variance in detection.

Wang and Owens conduct research for the Arkansas Agricultural Experiment Station, the research arm of the University of Arkansas System Division of Agriculture. Owens also teaches classes through the Dale Bumpers College of Agricultural, Food and Life Sciences at the University of Arkansas. Wang teaches classes through the University of Arkansas’ College of Engineering, and has a split research appointment between the biological and agricultural engineering department and the food science department. Pallerla holds a teaching assistant position in the biological and agricultural engineering department.

To learn more about Division of Agriculture research, visit the Arkansas Agricultural Experiment Station website: https://aaes.uada.edu.

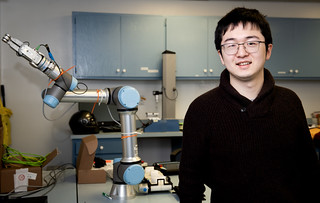

Headline image: Graduate assistant Chaitanya Kumar Reddy Pallerla investigates the use of hyperspectral imaging to detect a defect in chicken meat.

All images courtesy of Fred Miller