How producers can profit from predictive data

Big data is coming to the poultry industry - find out what it can do at farm level.A year ago we interviewed Caroline Forest, of agritech company Intelia, who gave us her perspective on how data is revolutionising the poultry industry. We caught up with her at IPPE 2019 to learn about her own company’s new technology and what it can do for producers.

Based in Québec, Canada, Caroline Forest has spent most of her career in agriculture working in greenhouses and supplying equipment to growers, before coming to Intelia three and a half years ago. As chief marketing and sales officer at the agritech company, her role is to help them launch the data analytics side of the business and to help producers see what it can do for them.

Intelia’s offerings include Internet of Things (IoT) devices and sensors for the poultry house. Such equipment can be used to capture such metrics as static pressure, bird weight, light levels, temperature, power to fans and equipment, ammonia levels, water usage, humidity and feed-bin weight.

Each sensor sends its data to a cloud-based management system where producers can view their data in an easy-to-interpret format.

“It’s a little bit like a black box on an airplane. You have a black box on a plane no matter if it’s an Airbus or a Bombardier – they all have a black box.

“Well, we install the black box in the chicken house. And then we pull the data from that house and we bring the data on to a web-based platform, where you can see all of your houses in real time and where you can do cross analysis.”

What sets them apart

Such technologies are becoming increasingly available to both broiler and egg producers, but many agritech firms, such as Hotraco Agri, Jansen and Greengage, to name only a few, as well as Intelia, are all still trying to build their respective niches.

“We also augment the data by pulling it through predictive models, giving you visibility into what could happen before it happens,” says Caroline, arguing that this is the main point of difference between Intelia and similar companies operating in the space.

“We do predictive models. We don’t just do beautiful graphs and dashboards. We also predict stuff” – and accurately, asserts Caroline.

With broiler production becoming increasingly competitive, anything to take the uncertainty out of things is a welcome change. Many producers we spoke with are eager to adopt new technology that can help overcome roadblocks to production, or at least to gain the tools to see them coming. If they do face any challenges, the data from such systems can go a long way to pinpointing the causes.

In Intelia’s case, the value the data bring to the producer is in broiler weight predictions. They take data from their IoT sensors, many of which they have designed themselves, send that data to the cloud in real time and process it to give accurate insights to producers. This system is called the COMPASS Data Analytics Platform, and it is powered by artificial intelligence.

“That’s where you add value,” says Caroline. “You process data and you don’t just supply more data to the producer. You give them insight with which they can take actions.”

So what kind of insights does Intelia provide?

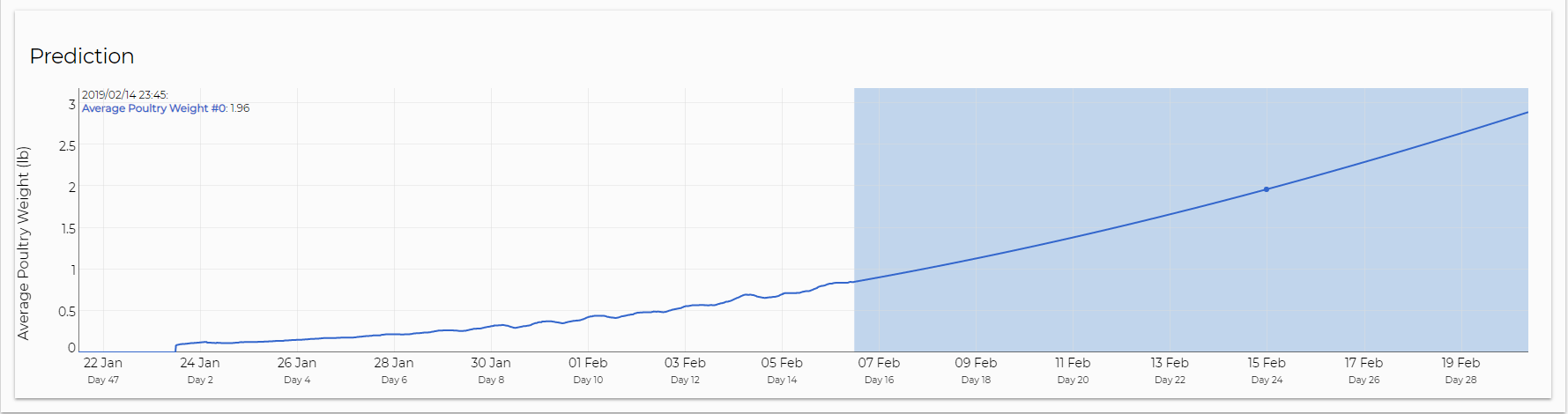

“We provide producers with 14 days of visibility into their weight prediction.” Caroline shows me a model on a screen in front of us, displaying data from an actual broiler house in Canada. “You can see that today these birds are at 0.88lb [0.4kg]. You can see here how that weight is going to evolve over the next 14 days.

“For example, let’s say the target weight is 2.5lb [1.1kg]. That’d be a very light bird, but I can tell you that bird will reach that weight at exactly 4:30pm on 17 February 2019.”

As impressive as this predictive modelling is, any producer will want to know how accurate such predictions are. If producers are going to make important decisions about their operations, insights ought not only to be timely, but close to reality as well.

Intelia, it appears, has thought of everything. “This prediction, because it’s in the later part of the 14-day period, has an error margin of just 0.25lb (+/- 0.125 lb). When the prediction is 7 days or less, the error margin is even smaller at around 0.125 lbs (+/- 0.0625lb).

“It’s a self-learning algorithm, so the more flocks you do with our system, the greater the accuracy will be. It takes into consideration not only the current flock, but all of the past flocks it’s had in this house with this breed.”

What producers can do with predictive modelling

At the farm level, such prediction allows producers to see if their birds are due to be moved next Thursday, for example, and if the birds will have reached target weight by that time.

“But if the birds are going to be above that weight,” says Caroline, “well, the producer could just adjust the lighting to provide more darkness hours, so the birds will eat a little less and that will slow the growth curve a little.”

Alternatively, if the birds were going to be too light, she explains, then the producer could stimulate the birds with more lighting so that they would eat a bit more.

“It’s not a fool-proof science,” says Caroline, “but at least you have a chance, and you have that visibility – you have 14 days to correct anything that isn’t right, or if it’s not going in the direction you want.”

Which is much better than discovering whether birds were too heavy or too light when the settlement report comes at the end of the flock – which is usually when producers find these things out.

The practicality doesn’t end in the chicken house, though. Processors or integrators can use this data to establish a catching schedule based exactly on what they need.

Caroline says: “They have a sales call, for example, that calls for, say, 25,000 chickens of 5lb. They can look at this dashboard and look at all the farms they have connected, find the seven-day weight prediction and sort them so that they can see which houses will meet the 5lb target weight that the sales forecast is calling for.”

Rewarded by processors

I ask Caroline about how this technology has actually been received by producers so far. “They really, really like it because it allows them to be in that sweet spot, where they get a premium for their chicken and they get rewarded by the processor and integrator for providing a chicken that’s in the best weight range.”

It’s a system that works across borders as well. Intelia is currently operating in the US and Canada, and has recent embarked on a project in Mexico. Caroline says that you can adapt the system to your unique context. For example in Canada, where poultry meat is not vertically integrated, producers can use access to their data as a negotiating tool for discounts on feed prices or a premium price for their chicken

Caroline assures me that producer data is kept extremely secure, and producers have the rights to their own data and can deactivate access if they choose to. The producer, in this way, maintains their independence and decisions about production ultimately remain on the farm level.

“Independence is important,” Caroline explains, “because the producer is paid for that work and should have responsibility for it. Our system helps struggling producers benefit from the insight it can provide.”

When it comes to set-up, Intelia’s system can integrate with the majority of third-party sensors, so producers aren’t required to purchase anything new – with the exception of those sensors which are required for the predictive modelling. In that case, Caroline adds, Intelia offers a bundle so that the price of equipment is included in the monthly subscription to access the platform.

It may not be long until we hear from Intelia again, since they are currently working on a variety of other predictive models to make producers’ lives easier. “We’re here for the producer,” concludes Caroline.