Improving Transport Performance

Hatched chick transport conditions can significantly subsequent health and performance and so should not be neglected, says Gerd de Lange of Pas Reform.

|

The transport of day–old chicks from hatchery to farm has a critical role to play in subsequent performance. Hatcheries operate in a fully controlled indoor environment, while transport entails the risk of exposing the chicks to uncontrolled, outdoor conditions.

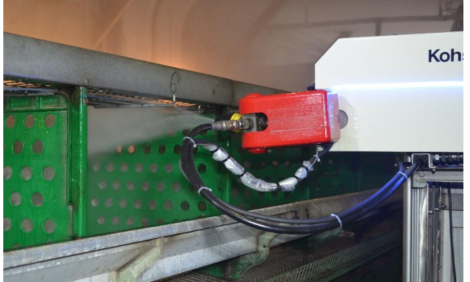

The modern hatchery is a major investment in state-of-the-art science, technology and engineering. It therefore makes sense to create a professional, modern chick transport fleet, specifically designed to maintain an optimised environment, to ensure that the birds arrive at the farm in the same condition in which they left the hatchery.

Day–old chicks are naturally well equipped for transport. Born with a residual yolk, they are comfortable without feed and water for up to two days, providing that temperature inside the chick boxes is kept within their thermoneutral zone. Within this narrow temperature range of 32 to 35°C, the chick’s metabolism is just at maintenance level with minimal heat production and water loss.

If temperature inside the chick boxes rises above this range, the chicks will start to use energy from the yolk sac at a much faster rate, to facilitate panting behaviour in an attempt to maintain optimal body temperature of 40.0 to 40.5°C. Proteins used for this purpose are then no longer available for the development of the immune and digestive systems. Panting results in water loss, with the risk of dehydration.

When the temperature at chick level is below the thermoneutral zone, the day–old chicks are forced to use their own resources for thermoregulation, rather than for growth and health. In general terms, temperature stress causes discomfort while also suppressing efficient production.

Temperature inside the chick boxes should be kept at thermoneutral zone by balancing the heat produced by the day–old chicks with the amount of temperature-controlled air flowing through the boxes. The optimal temperature of air circulating inside the truck is dependent on air velocity: the higher the speed of the air, the higher the optimal temperature and vice versa. Well mixed, preconditioned inlet air must flow uniformly through all the boxes, effectively absorbing and dispersing the metabolic heat, moisture and carbon dioxide produced by the chicks. This should not only be the case in fully loaded trucks, but also in case of partial loads.

Transport conditions are still too often neglected, when in fact they have the potential to significantly affect growth rate, feed conversion, meat yield and the development of the immune system. Optimising these conditions is highly beneficial for subsequent performance on the farm.

Advice

- Realise the importance of optimising transport conditions from hatchery to farm for subsequent performance. Judging the quality of transport solely by the number of dead chicks on arrival is inadequate.

- Choose reliable chick transport trucks, capable of operating independently from driving speed within the range of prevailing, external climatic conditions in the geographic location of your hatchery and customers.

- Maintain a temperature of 32 to 35°C inside the chick boxes by optimising both the temperature of circulating air and its velocity.

- Work quickly during the critical process of loading and unloading when no forced ventilation is present and/or provide sufficient space between individual chick boxes.

- Take the location of temperature loggers into consideration while reviewing the output; avoid direct contact between chicks and sensors!

- Adjust the number of chicks per box if optimal temperature inside the chick boxes cannot be achieved due to limitations in transport equipment.

- Ensure that drivers are well trained and motivated: their professionalism contributes significantly to optimised chick transport.

May 2012