Introducing Axxess XY: Full flexibility in feed performance with a next-generation xylanase

Axxess XY is a leap ahead, giving animal nutritionists and feed producers full flexibility for feed performance.In the 30+ years since xylanase was first introduced in broiler diets in Europe, few, if any, major improvements were made. While the animal feed industry evolved in terms of production landscape, feed processing technologies and use of various by-products, xylanase technology did not keep pace. In fact, it did not evolve to meet the customers’ changing needs and provide that much-needed flexibility of diet formulation for a commercial nutritionist. EW Nutrition, part of a group dedicated to the animal production industry, with in-house innovation, development, and production capabilities, undertook the massive improvement project and is now proud to introduce Axxess XY – for full flexibility in feed performance.

Current or earlier generation xylanases, or xylanase-based NSPase solutions, are confronted with serious challenges posed by developments in the industry. Axxess XY was designed to address and solve these exact challenges for the 21st century.

Pelleting stability

To achieve the desired feed hygiene, pellet quality, and animal performance, feeds are pelleted at higher temperatures and longer conditioning times (more than 120 seconds, even up to 360 seconds). EW Nutrition specifically addresses this challenge by sourcing its enzyme from a bacterium (Thermotoga Maritima) from hot springs near volcanic grounds. This gives Axxess XY an evolutionary advantage to deal with not only high temperature, but also moist conditions, without any coating. This is truly a step forward in xylanase thermostability and flexibility in application, in very diverse feed processing conditions.

Resistance to xylanase inhibitors

Cereal plants have developed a protection mechanism to resist pathogenic (especially fungal) invasion, by producing xylanase inhibitors. These inhibitors are present in all types of cereal grains, including wheat, corn, rice etc. They can affect the overall efficacy of xylanase, as many of the xylanase inhibitors can even resist pelleting temperature challenges. To achieve true flexibility, especially when you want to use mixed diets with added locally available cereals, it is crucial to have a xylanase that is resistant to xylanase inhibitors. This challenge was also taken on in Axxess XY development, and as a consequence Axxess XY is not inhibited by xylanase inhibitors. This gives nutritionists a much-needed peace of mind on the topic of achieving consistent performance.

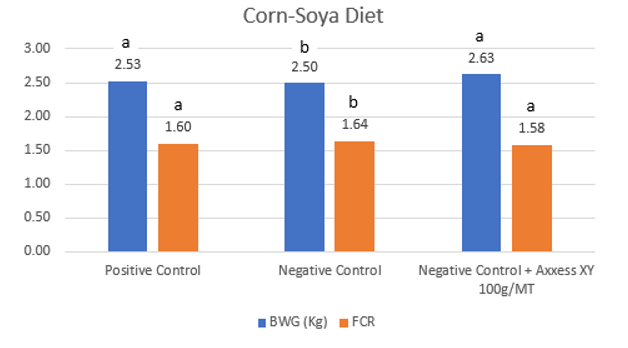

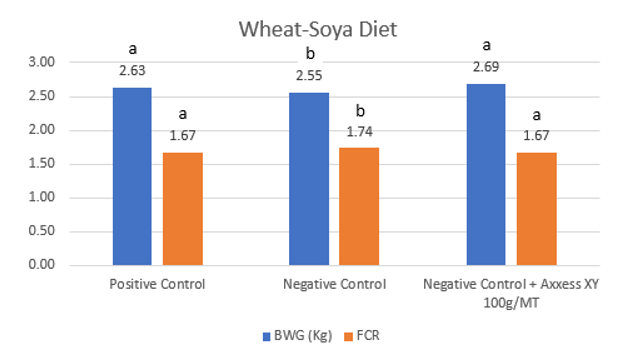

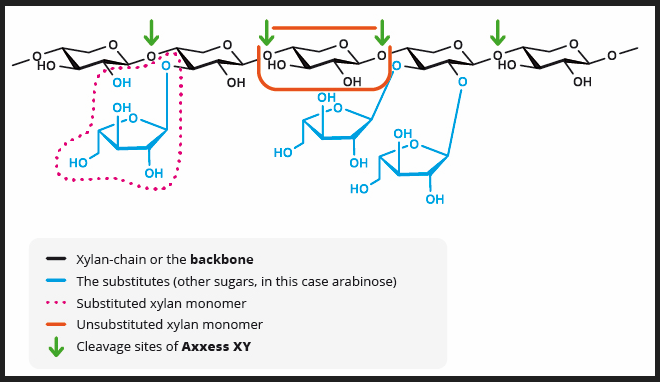

Equally efficient in breaking down soluble and insoluble arabinoxylans

Earlier generation xylanases were primarily developed to reduce viscosity triggered by soluble arabinoxylans in wheat and barley-based diets. These xylanases were mainly of fungal origin and from the GH-11 family. They had their structural and functional limitations when used for corn soya diet or diets high in byproducts due to presence of mainly insoluble arabinoxylans. Axxess XY changes that. With bacterial GH-10 origin, Axxess XY gives nutritionists full formulation flexibility to use all kinds of cereals and oilseed cake-based ingredients. This helps them save feed cost, without losing animal performance.

Improving gut health to contribute to antibiotic reduction strategies

With its versatility and ability to work on both soluble and insoluble arabinoxylans, Axxess XY creates mixed breakdown products inside the gastro-intestinal tract, such as xylo-oligosaccharides and arabino-xylo-oligosaccharides. This gives in-situ prebiotic effects. Axxess XY has been demonstrated to improve bifidobacterial population and to reduce clostridia in caecal samples in broilers. This prebiotic effect also contributed to improve manure quality and reduction in dirty eggs in layers.

Axxess XY addresses challenges that the developments in animal feed formulations and production have put forward. Axxess XY, a new generation xylanase, is a leap ahead, giving animal nutritionists and feed producers full flexibility for feed performance.