Lighting for Poultry Farms and Processing Plants

Joseph M. Zulovich Department of Agricultural Engineering, University of Missouri - Poultry businesses and poultry industry specialists have known for years the value of specialized controlled lighting for stimulating bird growth and egg production. But the very low lighting level (usually 2 foot-candles or less) required for better egg production has often led to low worker productivity. Houses are windowless to control light, summer heat, winter heat loss and year-round ventilation.

Well-designed artificial lighting systems allow workers to perform tasks easily, efficiently and safely. This is also true for related agri-industry processing plants often located in rural areas close to producers. Great emphasis placed on consumer protection and satisfaction brings strict sanitary practices in food processing facilities. Proper illumination helps achieve these objectives.

Lighting systems must provide proper quantity, quality and color of light. Worker comfort and safety is important, but light is also needed for production efficiency and for poultry protection, whether birds are housed or reared on the range.

- Lighting levels desired to perform specific tasks.

- Factors affecting light quality.

- Room characteristics and reflectivity factors.

- Type of lamps and luminaries used.

- Illumination level and lamp output relationships.

- Room height and lamp spacing relationships.

- Types of supplementary lights for specific jobs.

- Care and maintenance of the system once it is installed.

The tasks that workers and poultry specialists perform require different levels of illumination, some low and some extremely high. Recent studies by a joint Farm Lighting Committee (members of the American Society of Agricultural Engineers, and the Illuminating Engineering Society) provide new guidelines for designing good lighting systems.

Specific levels of illumination in Table 1 relate to worker productivity, not to bird growth or egg production. A lighting system should provide the recommended foot-candle level at any time during the life of the lamps, even after the lighting system has depreciated or has collected dust and dirt. Consequently, the initial system design should provide a slightly higher level than those given in Table 1. Data were obtained with scientific measuring equipment and in consultation with poultry specialists at Cornell University, Ithaca, New York.

| Table 1: Recommended illumination levels for poultry farm and industry tasks | |||

| Areas and visual tasks | Foot-candles | ||

| Brooding production and haying houses

feeding, inspection and cleaning read charts and records read thermometers, thermostat and time clock |

20 30 50 |

||

| Hatcheries general and loading platform inspect and clean inside incubators dubbing station sexing |

20 50 150 1,000 |

||

| Egg handling, packing and shipping general cleaning inspecting for egg quality loading platform, egg storage area, etc. |

50 50 20 |

||

| Egg processing general lighting (clean-up for food preparation areas) |

70 |

||

| Fowl processing plant general lighting (clean-up) government inspecting and grading unloading and killing |

70 100 20 |

||

| Feed storage prepare and process feed rations read charts and records |

10 30 |

||

| Machine storage move machinery in and out safely |

5 |

||

| Farm shop active storage area general shop lighting — machinery repair rough bench — machine work (painting, sheet metal work, welding) medium bench — machine work (metal lathe, grinding and drill press) |

10 30 50 100 |

||

| Miscellaneous farm office (bookkeeping, etc.) restrooms pump house |

50 30 20 |

||

| Exterior general inactive areas (discourage prowlers) light barn lots, paths, rough storage service areas (fuel storage, shop feedlots and building entrances) |

0.2 1 3 |

||

Good quality light prevents glare. Glare is controlled by shading windows, shielding lamps and by painting interior surfaces with a flat, non-glossy paint for a "matte" finish.

When practical, improve light quality and obtain more useful light by painting ceilings, walls, floors, and equipment with a white or light color. Ceilings should reflect 80 percent of the light striking them; walls, 40 to 60 percent; and floors at least 20 percent. As a guideline, the reflective value of white cement is about 50 percent. Color reflectance charts are available from most paint dealers.

Great differences in brightness between a lighted task area and the remainder of the room can be annoying and often uncomfortable. Therefore, it is desirable to have a brightness ratio between light and dark areas of 2 to 1 for difficult seeing jobs; a ratio of 5 to 1 for less critical tasks.

Lighting equipment compared

A comparison of three common lamp types listed in Table 2 is a general guide. While there is little difference in the amount of light emitted by a particular size of standard incandescent lamp, the lumen output (the total amount of light emitted from a lamp or luminary) of a specific size of fluorescent lamp varies considerably with color and design. Values in Table 2 are for daylight fluorescent lamps. Lumen output of mercury lamps also varies with design and degree of color correction built into them.

| Table 2: General comparison of lamp type and output | |||

| Incandescent (standard) | |||

| Average life -- 750 to 2,500 hours Factors affecting average life -- vibration Relative light output near end of lamp life -- 80 percent of initial output Comments Use "rough service" lamps where subject to vibration or shock (example: portable cords) |

|||

| Watts | Average output (lumens) | Average lumens per rated lamp watts1 | |

| 25 | 225 | 9.0 | |

| 40 | 430 | 10.8 | |

| 60 | 810 | 13.5 | |

| 100 | 1,600 | 16.0 | |

| 150 | 2,500 | 16.7 | |

| 200 | 3,500 | 17.5 | |

| 300 | 5,490 | 18.3 | |

| 1Power for ballasts must be added | |||

| Fluorescent (standard) | |||

| Average life -- 7,500 to 20,000 hours (based on 3 hours of operation per start) Factors affecting average life -- number of starts, ballast type Relative light output near end of lamp life -- 80 percent of initial output at 85 percent or rated life; 68-70 percent at end of life Comments -- Diffuse light more uniformly over broader areas than do incandescent of mercury lamps |

|||

| Watts | Average output (lumens) | Average lumens per rated lamp watts1 | |

| 20 | 900 | 45.0 | |

| 40 | 2,300 | 57.5 | |

| 60 | 3,300 | 55.0 | |

| 100 | 5,500 | 50.0 | |

| 210 | 11,000 | 52.4 | |

| Mercury | |||

| Average life -- 16,000 Factors affecting average life -- number of starts, ballast type Relative light output near end of lamp life Up to 87 percent of initial lumens near end of economic rated life Comments Most require special fixtures and ballast. Only mercury lamps with less efficient built-in ballasts can interchange with incandescent lamps. If power is interrupted, lamp must cool before it will restart. |

|||

| Watts | Average output (lumens) | Average lumens per rated lamp watts | |

| 75-85 | 2,000 | 26.7 | |

| 100 | 2,800 | 28.0 | |

| 175 | 6,000 | 34.3 | |

| 250 | 9,500 | 38.0 | |

| 400 | 18,000 | 45.0 | |

| 700 | 31,000 | 44.5 | |

For a more accurate comparison of efficiency, lumens-per-watt-factors for fluorescents must generally be reduced from 20 to 30 percent to offset power consumed by the ballast, which produces heat and not light. For mercury lamps, the lumen/watt factor must be lowered by about 11 to 14 percent to account for energy used by their ballasts. (These adjustments were not made in Table 2 because of wide differences in energy consumed when one, two or more lamps are used with a specific ballast).

When accounting for power consumed by ballasts, fluorescent lamps are 2.5 to 3 times more efficient to operate than incandescent lamps and 1.5 to 1.8 times more efficient to operate than mercury lamps. The life of mercury lamps is 1.5 to 2.0 times as long as fluorescents; and life of fluorescent lamps is 7.5 to 12 times as long as incandescents. The life of fluorescent and mercury lamps may be longer than shown in Table 2 if operations average more than three hours per start.

Where to use different lamp types

Electric lamps give off light in nearly all directions. Properly selected, they will direct light where you need it.

All light from incandescent and mercury lamps comes from a "point" source. Even though incandescent bulbs are usually coated to reduce glare, fluorescents diffuse light more uniformly over a broader area. Most rapid-start fluorescent lamps are made with invisible silicone coating that disperses moisture film. This ensures reliable starting where high humidity conditions exist.

Incandescent or fluorescent lamps will satisfy interior lighting needs. Incandescents are recommended when lamps must be switched on and off for short time periods. Mercury lamps are suited to outdoor applications and normally mounted at heights of 16 feet or more. However, they require a 5- to 10-minute warm-up period between stop and start. Mercury lamps are not as efficient as fluorescents. But lamps in the 300- to 400-watt range give twice as much light per watt of energy as incandescents. With long life and low maintenance, the higher fixed cost of mercury often can be justified for outdoor lighting jobs. The outdoor lighting guide in Table 3 is from USDA Farmers Bulletin No. 2243.

| Table 3: Outdoor lighting recommendations | |||

| Area or activity | Recommended foot-candles | Typical installation1 | |

| Protective lighting | 0.2 | 175-watt mercury refractor mounted 25 feed high for lighting 8,000 sq. ft.; or incandescent floodlight2 | |

| General work areas, driveway, walks, barn lots | 1.0 | 400-watt mercury refractor mounted 25 feet high for lighting 8,000 sq. ft.; or incandescent floodlight2 | |

| Activity areas, fuel storage, building entrance, electrical load center, feedlots and equipment, livestock loading, recreation area | 3.0 | 400-watt mercury refractor mounted 25 feet high for 2,000 sq. ft.; or incandescent floodlight or spotlight | |

| 1Typical installation based on ratings of clear mercury lamps. 2Distance between lamps should not exceed 5 times mounting height. |

|||

System plans and layout

Specific factors affecting overall performance of lighting systems are room size and height, color of walls, ceiling and equipment, type of lamp and luminary, and lamp height and spacing. Generally speaking, most luminaries can be suspended from 7 to 10 feet above the floor in poultry buildings. Interior surfaces can have from medium to average reflectance values.

With the above assumptions in mind, use one basic guideline to account for most of the judgment factors of design: allow 2 lumens of lamp output for each square foot of floor area to provide a lighting level of 1 foot-candle.

Lamp and luminary height and spacing is related to the uniformity of light to be obtained. Agricultural and lighting engineers recommend that lamps be spaced a distance of 1 to 1-1/2 times their mounting height if the desired illumination level is between 5 and 10 foot-candles. If the lighting level is to be higher than 10 foot-candles, the lamp spacing should be limited to its mounting height. When using the former spacing with incandescent lamps, use shallow dome reflectors; when using the latter spacing, use standard dome reflectors. With either, the distance of outside lamps to walls should be no more than one-half the distance between lamps.

Applying the guidelines and recommendations

A typical problem can serve to illustrate how the data can be applied. Let us assume that we must plan a lighting system for a 20 x 40 foot egg handling room with light colored walls and ceiling. The ceiling height is 8 feet.

Table 1 shows that we need 50 foot-candles (ftc.) for inspecting and for general cleanup. Our "lighting guideline" calls for 2 lumens/sq. ft./ftc. Therefore:

Floor area is 20' x 40' or 800 sq. ft. and, 800 sq. ft. x 2 lumens/sq. ft./ftc. is 1,600 lumens for each foot-candle requirement. So, 1600 x 50 ftc. (level required) is 80,000 lumens or, total amount of light required for the handling room is 80,000 lumens.

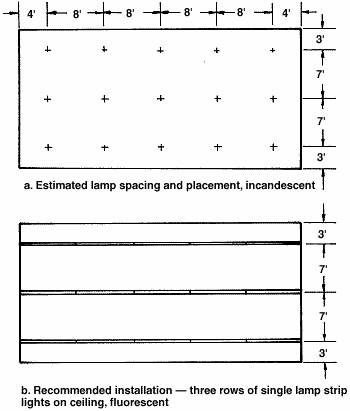

Since this is a high level of lighting, our maximum lamp spacing should not exceed the floor to ceiling height of 8 feet; and since the first row of lamps cannot be more than 4 feet from each of the long walls, we'll need at least three rows of lamps. Thus, let's estimate use of 15 lamps placed as shown in Figure 1. This means that each of the 15 lamps must have an output of or 5,333 lumens (or 80,000 ÷ 15).

Figure 1: Egg handling room lighting system design

Referring to Table 2, we see that we would need a 300-watt incandescent lamp if we chose that type. The low mounting height might cause bright spots and eye discomfort for workers near the light sources. So if we chose incandescent lamps, we may prefer more lamps spaced closer together with small bulbs for uniform lighting.

A fluorescent system appears more desirable since the light from the "line" source is spread over a broader area and is more diffused. Fifteen fluorescent single-tube 100-watt lamp and fixtures, as located in Figure 1b, would meet our criteria. Since the 100-watt lamp is approximately 8 feet long, the system would be three continuous lines of single fluorescent lamps, making a uniformly lighted egg handling room. The lamps should be shielded to prevent glare. Make a cost comparison of 15 fluorescent fixtures vs. 21 or 24 incandescent fixtures at local prices.

Fluorescent lamps and fixtures are higher in first cost than incandescents but fewer fluorescents are needed. With higher efficiency considered, along with fixed cost comparison, fluorescents will usually give the most light per dollar investment for lighting rooms of this type.

To continue with the lighting system design, locate a 300-watt incandescent lamp in an outdoor fixture. Place it 8 to 10 feet above the loading platform. If an egg storage area is located nearby, calculate the lighting as above but on the basis of 20 ftc. (rather than the 50 ftc.) for the egg handling area. Be sure to provide adequate wiring to limit voltage drop to 3 percent inside the building.

Special lighting considerations

Supplementary lighting is the most economical and practical way to achieve the high foot-candle levels required for specific tasks such as sexing. Such tasks are usually performed in small areas where supplemental lighting is more practical. R-40 flood or spot lamps with built-in reflectors are a good choice. Tungsten-iodine lamps can also be used. Where they are used in dusty locations or in explosive atmospheres, lamps should be enclosed in dust-tight reflectors. Revolving tools, like grinding or buffing wheels, should be lighted with incandescent lamps to avoid hazardous stroboscopic effects that can be created by some fluorescent lamps. (Fluorescent lamps will sometimes make running tools falsely appear to be at a standstill). Deep-bowl reflectors will concentrate incandescent lamp light onto the working area.

Electrical wiring important too

Most lamps are rated at 120 volts for single-phase wiring systems. When purchasing them, don't take this for granted — check the voltage rating stamped on the lamp itself. Your wiring system should be designed for a minimal voltage drop from the transformer to the lighting outlet. The outlet voltage should be within 3 or 4 volts of rated lamp voltage. Too high a voltage will increase light output but will greatly shorten lamp life. On the other hand, too low a voltage will increase the lamp life but will give considerably lower light output.

Always use UL (Underwriter's Laboratories) approved wiring, fixtures and wiring materials. If wiring is to be installed in a wet, corrosive atmosphere, use type NMC or UFNMC grounded cable; if underground, use type UF or USE. For overhead exterior use, use the proper size of "tri-plex" for easy maintenance of minimum clearances and for a neat appearing farmstead.

Ample use of 3- and 4-way switches will allow you to have "switch ahead" lighting systems — systems that will allow you to light up paths, walkways, stairs and entrances before you use them and then allow lights to be turned off after you have reached your destination. All lights should be properly controlled at, in, or from frequently used buildings if they are to serve maximum usefulness in convenience, efficiency and safety.

System maintenance

Any well-designed lighting system will deliver the light for which it was designed only if the system is properly maintained. A good maintenance program involves prompt replacement of blackened or burned out lamps, washing lamps and luminaries, periodically cleaning and repainting walls and ceilings on a scheduled basis.

A check of illumination levels with a simple foot-candle light meter, immediately after installation and again at three-month intervals, will help you set up a maintenance schedule for your particular conditions. Such checking should be done over a full-year period to account for seasonal variations in dust and dirt collection. A light meter can often be borrowed from a power supplier, extension home economist, or from a local physics teacher.

References

ASAE Recommendation R332, Poultry Industry Lighting, pp. 409-412, Agricultural Engineers Yearbook, 17th ed., 1970.

Farm Lighting, Farmers' Bulletin No. 2243, December 1969. U.S. Government Printing Office.

Source: Published by University of Missouri Extension - Updated July 2005