Maintaining Egg Shell Quality

This is a three-part series of articles analysing egg shell quality. It was written by Dr Lokesh Gupta, Regional Technical Manager, Avitech.Part 2: Factors Influencing Shell Quality

Part 3: How to Improve Shell Quality

Poor egg shell quality is a huge hidden cost to the egg producer. Estimates are that more than 10% of eggs produced in the hen house are uncollectible or break before intended use. The first 2-5 percent is lost simply , due to form which may be shell less, cracked or broken to the extent that they are not suitable for collection. Another 3-8 percent is lost during collection, moving through the belts, cleaning, packing and transportation to the end user. Because the first 2-5% loss is due to uncollectible eggs, most egg producers often estimate their egg loss due to poor shell quality at only this percentage, which is most likely an underestimation. At Rs.1.50/ egg, even a 5 percent loss could be as much as Rs. 2.7 million/year for 100 thousand layer house. The economic losses for the breeders will be even more due to reduced hatchability and chick livability. Therefore, every effort must be directed towards improving shell quality and reducing egg breakage.

Egg: The fertile egg is highly complexed reproductive cell and is a tiny center of life, where initial development of embryo takes place. Most of the commercial eggs are infertile. The yolk is surrounded by albumen, having high water content, elasticity and shock absorbing capacity. This entire mass is surrounded by two membranes and an external covering called egg shell. The shell provides a proper shape to the egg and is meant for conserving the valuable nutrients within the egg.

Hen egg contains approximately 76% water, 12% protein, 10% lipids and rest vitamins, minerals and carbohydrates. Egg is a major source of human dietary protein with high biological value and excellent protein efficiency ratio.

Egg Shell: The outer cover of the egg, the shell comprises 10-11% of total egg weight. On an average the eggshell weighs 5-6g, with remarkable mechanical properties of breaking strength (>30N) and is 300-350 micrometer thick. This structure plays a crucial role in protecting the contents of the egg from the microbial and physical environment and in controlling the exchange of water and gases. The calcium content of the eggshell is approximately 1.7-2.5g. An average eggshell contains:

| Calcium carbonate | :94-97% |

| Phosphorus | :0.3% |

| Magnesium | :0.2% |

| Sodium, Potassium, Manganese, Iron and Copper | :traces |

| Organic matter | :< 2% |

|

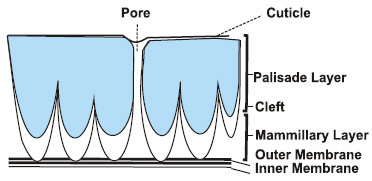

| Fig. 1: Structure of the egg shell |

The small amount of organic matter mostly consists of matrix proteins (mixture of proteins and polysaccharides rich in sulphated molecules) and shell pigment. The matrix proteins are critically important in determining the egg shell structure and serves as foundation for the deposition of calcium carbonate.

There are about 8000 microscopic pores on the shell. The outer surface of the shell itself consists of a mucous coating (cuticle) which is deposited on the egg just prior to the lay. This proteinous covering helps to protect the interior content of the egg from bacterial penetration through the shell.

Shell Quality: The aesthetic quality of the egg shell relates to the quality factors which one can observe; such as soundness of the shell, shape of the shell and colour of the shell. However, for commercial layer and breeder operations, shell quality means increased shell thickness and shell breaking strength to reduce number of cracked eggs, an increased number of saleable/ hatching eggs and a higher number of viable day old chicks.

Methods to Measure Shell Quality: On farm methods and sophisticated equipments are available for accessing shell quality parameters. The egg shell strength is the main, but not the only factor that determines shell quality. Egg shell quality can be measured as:

- Egg size and visual shell defects

- Specific gravity

- Shell colour

- Shell breaking strength

- Percentage shell (Shell weight X 100/Egg weight)

- Shell thickness (mm)

- Ultrastructure of the shell

The specific gravity of an object equals the weight of its volume relative to the weight of an equal volume of water, when both are at the same temperature. The specific gravity of an egg is equal to the egg’s density relative to water. The specific gravity of all four parts of the egg is different (shell: 2.325, Yolk: 1.032, albumen: 1.038, shell membranes: 1.075). Since the specific gravity of shell is more than two times higher than the other parts of the egg, the percentage of the shell has major influence on the specific gravity of whole egg. As the amount of shell increases, the specific gravity of the egg increases. Egg specific gravity, therefore, is a good indicator of percentage shell and shell quality.

The incidence of breakage is above normal, if the specific gravity of a flock averages less than 1.080.

Shell breaking strength can be measured through shell force gauge (static compressor) and is expressed in dynes/cm²(N).

Maintaining egg size, proper and routine candling and measurement of specific gravity can be easily practiced at farm level.

Shell Quality Defects: These defects are obvious from direct external observation/ candling and are important for evaluation for the producer and consumer. It is also the main criteria for selecting hatching eggs. These may be as :

| a) |

Misshaped Eggs: If albumen quality is very poor and there is no sound foundation upon, which to build the true shell; The result can be the distinctive ‘crinkled’ shell typical of certain viral diseases. Misshaped eggs can also arise for other reasons. i.e, the shell may break in the shell gland during the formation process; The damage can be partly repaired but a bulge forms around the centre of the egg (an equatorial bulge). Any factor which causes disturbance to the birds 10-14 hours before the egg is laid is likely to increase the incidence of this fault. |

|

|---|---|---|

| b) |

Coated Shells: Additional calcium may be deposited onto some eggs causing calcium splashing or a pink coloured egg. Typically these faults are caused by the egg remaining in the shell gland for an extended period. Often young flocks just coming into production are very susceptible to this defect. Any stresses or disturbances at the time when the egg is due to be laid will encourage the bird to retain the egg. |

|

| c) |

Rough Shelled Eggs: In some cases, two eggs may be in the shell gland at the same time which can cause a form of rough shelled egg often referred to as a ‘target’ or ‘thumb-print’ type. This problem can also result in ‘slab-sided’ eggs. There are other types of rough shelled eggs, including those with pimples or a sandpaper-type texture. |

|

| d) |

Soft and Weak Shelled Eggs:Soft and weak shelled eggs can be common in older birds, especially those which are nearing the end of the laying period, having produced a high output of eggs. Whenever they are seen in younger flocks, they can be associated with coated or rough shells. If an egg is retained in the shell gland for too long, the next ovulation takes place at the usual time but before the previous egg is laid. The second egg may spend less time than normal in the shell gland and the result is a soft or shell-less egg. In such cases, a hen may not lay an egg on one day, but may lay both a coated and a soft-shelled egg on the next. |

|

| e) |

Cracked Eggs: Egg shells can easily be damaged after the egg is laid and cracking is one of the most common reasons for downgrading. It may be due either to an inadequate egg shell being laid or to poor handling which may occur during collection, grading or transportation. Three main types of cracks are identified: |

|

| i) |

Hairline cracks are the most difficult to identify, particularly in very fresh eggs. Skilled candling is needed together with ideal working conditions. Hairline cracks are often caused by an egg colliding with an inflexible surface. |

|

| ii) |

Star cracks may often be visible under normal light although they are more asily seen during candling. A central point of impact may be seen and star cracks are often due to collision between eggs. |

|

| iii) |

Pinhole and toe-hole cracks can be caused either by the birds themselves or by any sharp protrusions which may come into contact with the egg. There is evidence that a fault which appears similar may occur before the egg is laid. which may |

|

| f) |

Dirty and Glazed Shells: After the egg is laid, it can become affected with numerous contaminants including faecal material, dust, mud, litter (in non-cage systems), blood and the contents of other eggs. The latter is often referred to as glazing or varnishing. All of these lead to eggs being downgraded. High standards of hygiene and management, coupled with appropriate diet formulation and pest control must be maintained to overcome this defect. |

|

| g) |

Body Checks: Sometimes during the egg formation, the egg is cracked while it is still in the body of the hen. These eggs which are commonly referred as "body checks" are repaired by an additional deposit of shell over the cracked area, resulting in a ridge having shells with thin areas and are weaker than normal eggs. With table eggs, it creates an increased risk of breakage en route to the consumer and lowers the utility value of the egg. With hatching egg, it is major factor contributing to cracks during storage and results in lower hatchability. |

|

Part 1: Maintaining Egg Shell Quality

Part 2: Factors Influencing Shell Quality

Part 3: How to Improve Shell Quality

March 2008