Maximising uniformity through top-level hatchery practice

By Ir Lotte van de Ven, Pas Reform Hatchery Technologies - The greatest challenge for modern hatchery is to achieve uniform, high vitality flocks of day old chicks. Next to incubation technology, good hatchery management can greatly influence this. Uniformity is an important issue for a hatchery, and the use of good hatchery management practices can make a valuable and lasting contribution, from the hatchery right through to farm level.

Traditionally, the emphasis on uniformity of broiler chicks has been dictated by the last part of the production chain. The automated slaughtering process demands uniformity of product entering the processing plant. Often, achieving uniformity is regarded as the broiler farmer’s job and indeed, uniformity of broilers at slaughter weight can be greatly influenced by what happens on the broiler farm. As chick uniformity is unlikely to increase during the production process, a key prerequisite to a uniform end product is uniformity in the day olds. Day-old flocks showing poor uniformity are impossible to manage properly, which will result in lower growth, increased feed conversion and higher mortality during the first week.

Flock uniformity

Flock uniformity - particularly during the

first week - is an important issue for management

because at the moment of hatching,

a number of physiological systems are

still developing in the chick, and this

process continues during the first seven to

ten days of life. Amongst these systems is

the thermoregulatory system. During the

first days of their lives, newly hatched

chicks have little or no ability to regulate

their body temperature. This means that as

environmental temperature decreases, the

internal temperature of the chick is also

reduced - and as small chicks have a higher

surface to volume ratio, they lose more

heat than large chicks.

Consequently,

small chicks may benefit from an environmental

temperature that is 2°C higher

than large chicks. Furthermore, an air temperature

that is too cool will prevent

chicks from getting adequate feed and

water. To conserve warmth, birds respond

by huddling together but are then unable

to get to feeder lids and drinkers.

Next to the development of thermoregulation,

the complete development of the digestive

tract and immune system is equally

important. Maturation of the digestive and

immune systems depend, in the first few

days, on the chick getting all the nutrients

and antibodies provided by the yolk sac. As

the uptake of nutrients from the yolk is

stimulated by the intake of feed, the development

and growth of the newly hatched

chick relies on having almost immediate

access to feed and water.

During the brooding period, the chick is

highly dependent on its environment.

Good management, especially during the

first days of a chick’s life, is crucial to maximise

performance and liveability. In order

to realise optimum environmental conditions

and feed/water supply for a maximum

number of chicks, uniformity of dayolds

is a prerequisite.

Next to providing optimum

conditions, having chicks separated

by size may reduce competition within the

flock, decrease mortality, increase growth

rate and improve uniformity of marketing

weight when the birds enter the processing

plant. Uniformity of day olds is therefore

highly valued by the farmer-customer.

Next to providing optimum

conditions, having chicks separated

by size may reduce competition within the

flock, decrease mortality, increase growth

rate and improve uniformity of marketing

weight when the birds enter the processing

plant. Uniformity of day olds is therefore

highly valued by the farmer-customer.

DOC uniformity

There appears to be general consensus

about the importance of chick uniformity.

However, some confusion arises when it

comes to the question of measuring uniformity.

Poultry growers generally assess the

uniformity of a flock ‘by eye’ – though in

general terms, information regarding practical

standards for measuring the uniformity

of day-olds is lacking. In broiler production,

uniformity is expressed as the

percentage of birds whose weight falls

within 10% of the flock’s average weight -

and current industry standards dictate

that to achieve good uniformity, 80-85% of

birds must fall within 10% of the average

flock weight. In day-olds, it is possible to

achieve 100% uniformity based on this

standard; hence this range may reasonably

be narrower than 10% for newly hatched

chicks (Figure 1).

For the purpose of this article, we will

take chick weight as a measure for uniformity

and focus on aspects of hatchery

management that affect the range of

weights in day old chicks.

Spread of hatch

Variation in day old chick body weight at

the moment of placement in the farm may

be much higher than the variation of newly

hatched chicks. The weight of chicks at

placement is affected by their weight at

hatch and the length of time they are held

in the hatcher. Chicks that have to wait in

the incubator for prolonged periods dehydrate

and lose weight. Spread in chick

weights upon placement - and thus uniformity

- is consequently influenced by the

spread of hatch.

Regarding spread of hatch, numerous

studies have investigated the effects of a

delayed access to water and feed for day

old chicks. Time until first feed/water intake

depends on the duration between

hatching and placement at the farm.

Spread of hatch within a batch of chicks in

one hatcher causes variation in the time at

which first feeds can be made available.

Thus, spread of hatch is likely to have similar

effects to variations in the time taken

to first feed intake, as measured in the

studies shown in Table 1.

The table summarizes recent results

from these studies, and clearly demonstrates

a negative effect on body weight at

eight days of age. The delay in feed/water

intake was shown to negatively influence

body weight up to slaughter age.

Differences in body weight were significant

when the spread in the time of access

to feed and water was more than 24 hours.

In multi-stage incubation, the hatching

process may take two days, and chicks are

removed from the incubator only when a

majority have hatched. From the results

shown above, we may conclude that chickens

hatched early will indeed show different

growth rates to late hatches up to

slaughter age.

Spread of hatch depends on equal development

of the embryos at the start of incubation,

combined with uniform rates of development

in the eggs within one incubator.

A number of factors are summarised

below, that are known to affect the spread

of hatch.

Maternal age

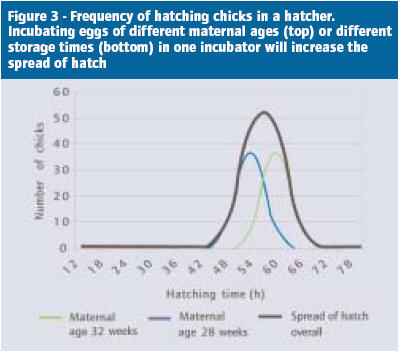

Maternal age influences day old chick weight through its effect on egg weight. On average, day old chicks weigh 67-76% of the initial egg weight. This is a considerable range, and although the influence of egg weight on chick weight is obvious, there are other important, influential factors that must be taken into consideration. Maternal age also directly affects the rate of embryonic development. It seems that at the moment of oviposition, the eggs of ‘mature’ flocks (>32 weeks) contain embryos in a more advanced state that develop at a higher rate than embryos in eggs from ‘pubescent’ flocks. Consequently, embryos in eggs from the latter group require longer incubation periods. Some studies even report a decrease in incubation time of up to 10 hours between 28 and 32 weeks of maternal age! (Figure 2).

Egg storage

Storage time prior to incubation is known

to influence the rate of embryonic development.

In stored eggs, the initiation of embryonic

development is delayed, and the

rate of development is also lower. Recently,

a study from the University of Leuven

(2003) confirmed the hatchery man’s rule,

that “one day storage adds one hour to in-

cubation time”, and indeed, embryos from

Cobb eggs stored for 18 days required an

additional 16 hours of incubation time,

compared to embryos from eggs stored for

three days. Incubating fresh and stored

eggs in one incubator thus increases

spread of hatch by one hour per additional

storage day!

It is important to realise that storage conditions

also have an impact on the rate of

embryonic development during incubation.

After oviposition, the temperature inside

the egg falls rapidly below the physiological

zero: the minimum temperature

above which embryonic development occurs.

However, temperatures below this

point influence other egg characteristics

too, thereby affecting egg quality - depending

on the duration of storage. Ruiz and

Lunam (2002) demonstrated a retardation

in embryonic development measured in incubation

time in eggs that were stored at

10°C for 9-11 days, compared to eggs that

were stored at 16.5°C: chicks that hatched

from the ‘cold’ stored eggs, required significantly

more incubation time.

Storage begins at the moment of laying.

Especially during the summer or in hot climates,

the time that eggs are held in the

breeder house should be minimised. In order

to maximise uniformity of embryonic

development, frequent collection of hatching

eggs is recommended.

Temperature

Naturally, a homogenous incubation temperature

during the entire incubation cycle

is fundamental to equal embryonic development,

as temperature directly affects

the rate of development in the embryo.

Normal embryonic development occurs between

37°C (98.6°F) and 38°C (100.4°F), but

the rate of development differs within this

range. Turkey embryos have been shown to

hatch approximately four hours earlier

when incubated at 37.5°C compared to

37°C (Christensen, 2001).

Of particular concern for a small spread

of hatch, is an even start of embryonic development.

A homogenous temperature for

all eggs within one incubator at the start

of incubation is fundamental to uniform

development for the batch. In this respect,

it is important to realise that batches of

eggs may require different heat-up times

to reach incubation temperature: for example,

because of different storage or transport

temperatures, or differences in egg

size. Consequently, incubating eggs of different

backgrounds may cause differences

in incubation times.

Optimise uniformity

Uniformity of day old chicks is a priority

for both hatcheries and their customers,

because improved chick management will

not only improve growth rates, but also decrease

losses from natural mortality or

culling.

The following is a useful summary of key

aspects of hatchery management that will

promote optimum chick uniformity:

Sort eggs. First, take flock age into account. The age of the mother flock affects egg size and furthermore, maternal age influences the development rate of the embryos (Figure 3). Eggs of young mother flocks (<32 weeks of age) require longer incubation time. Secondly, consider storage time. Eggs in one incubator should be of approximately the same age (storage time), since storage also retards embryonic development. For every storage day after three days, increase incubation time by ± 1 hour.

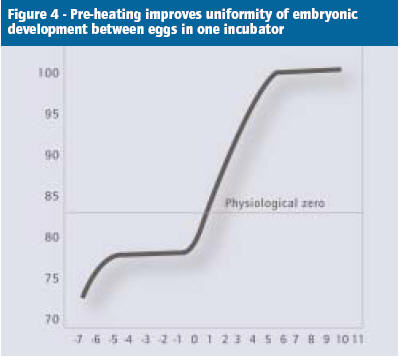

Pre-heating. Accurately sorting eggs prior to incubation enhances uniformity of embryonic development at the start of incubation. A uniform start may be further improved by pre-heating treatments prior to incubation. Eggs of various backgrounds may require different times to reach incubation temperature. Heating the eggs for several hours to 21- 25ºC reduces the variation of temperatures inside the eggs at the start of incubation (Figure 4). This will promote better uniformity of development in eggs within one machine and further reduce spread of hatch.

Homogeneous incubation temperature. Incubation temperature influences the rate of embryonic development - and crucially, homogeneous incubator temperature is required to achieve the narrowest spread of hatch. This means that incubators must be designed such that they provide uniform incubation conditions to support equal, synchronised embryonic development for each individual egg within the machine. The incubator should be divided into small, separate units, each with its own climate control. Supporting the natural pattern of the embryo and eggshell temperature during each phase of embryonic development means that optimum conditions vary during the incubation process. Consequently, optimum conditions for uniform incubation can only be achieved in single stage incubation.

Conclusion

A large spread in hatching time, and consequently in the duration to first feed/water intake, causes poor uniformity of day olds, which complicates farm management and undermines performance and results. Minimising spread of hatch is crucial for optimum results. There are two criteria that must be met for a uniform hatch:

- The hatching eggs entering the incubator must be uniform.

- During both the setting and the hatching period, the rate of development of each egg in the batch must be synchronised by a homogeneous incubation temperature .

The hatchery management methods

summarised here can greatly improve

day old chick uniformity. Application

in hatchery practice requires good

planning and the use of highly evolved

incubation technology, to assist and

maximise uniform embryonic

development.

Source: Pas Reform - November 2005