Meeting the challenge of cage-free egg production

Learn more about Hy-Line's assistance with cage-free systemsIn many parts of the world, farmers are responding to the increasing demand for eggs produced from cage-free layers. While this may be a daunting prospect for those producers with their roots in more intensive housing systems, the results from cage-free flocks demonstrate that with the appropriate management, production levels can match the results achieved in cage systems.

The management process starts with the rearing cycle. It is important to match the rearing system as closely as possible to the environment the birds will experience in the laying house. Many cage-free layers will be housed in aviary systems; therefore, it is important that pullets have learnt from a young age to navigate through the overhead equipment. This will be best achieved by rearing the flock in an aviary rearing system, but where this is not available, floor rearing systems should be fitted with aerial platforms and perching, with a proportion of the feed and water raised off the floor.

Feeder and drinker type should also match those in the laying house. While this concept seems simple, it is one that is often overlooked, making the transition from rearing to laying farm even more challenging for the pullet. A poor transition to the production house may lead to a body weight loss of up to 10 percent, and it is estimated that it may take the bird five weeks to fully recover the loss.

In a light-controlled environment, pullets will have generally been reared on a 10-hour day. On transfer, which is usually at 16 weeks, the addition of one hour to 11 hours of total light will stimulate feed and water intake and will help the process of regaining that lost body weight. How and when additional hours of light are added will depend on several factors, including the control over natural daylight, the body weight of the pullets, and the target egg weight. In contrast to cages where 14 hours of light is often the norm, birds in alternative systems may need a longer day length (up to 16 hours) due to the extra activity involved and to give them time to consume sufficient feed. One of the most crucial aspects of successful cage-free production is encouraging the birds to use the nests, and that process must start immediately after housing. The three-week period after housing and before first egg is a good time for the birds to find and explore the nests. With that in mind, soon after housing, the birds should be given access to the nests which will encourage the birds to find and explore them. Temporarily lifting some nest curtains will aid this process.

During this “pullet training,” nests should be closed two hours before lights-out, timing it with the last run of the feeder. Another important aspect is ensuring that the birds learn to go up onto the slats or system to roost. If they have been reared in an appropriate environment, this should come naturally; however, any birds that are still on the floor at lights-out should be lifted up onto the slats. While this can seem like an overwhelming task, the birds will very quickly learn.

By ensuring that the birds are ‘going up’ at night, this means that they wake up next to the feed, water and, crucially, the nest boxes. Once laying commences, birds should be “walked” regularly, while taking care not to disturb them in the nests. “Walking the birds” means having a worker enter the barn and walk through the flock to keep birds from settling in areas where they may be tempted to lay eggs, particularly against the sides of

the building, in corners, or in any darker areas. Floor eggs should be collected frequently to discourage other birds from imitating this behavior.

Birds will need ample opportunity to feed, which means running feeders five or six times a day. The first feed should be at lights-on, or shortly after, then a gap of four hours should be left before a further feed. This is done to avoid the feeder disturbing birds which may otherwise be in (or heading to) a nest.

The remaining feeds should be spread throughout the day, keeping in mind that the majority of a bird’s intake will be in the second half of the day.

When it comes to maintaining health status in cage-free flocks, the principles applied to more intensive production systems are exactly the same:

- Robust biosecurity;

- Comprehensive vaccination program tailored to any specific challenges on the production site; and

- Maintaining good air quality within a thermally comfortable environment.

There will be additional considerations, however, such as implementing a regular program against internal parasites.

For further information on cage-free management, consult the Alternative Systems Management Guide.

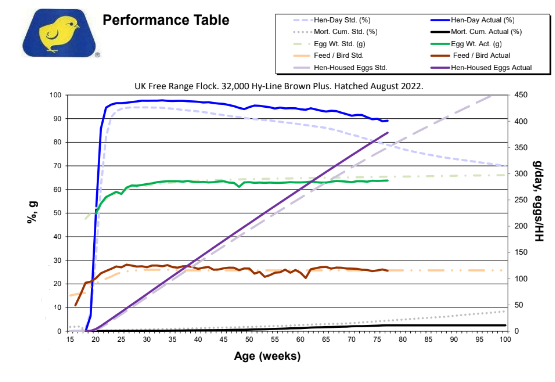

Excellent Cage-Free Performance for UK Producers

Producers Daniel and Trudi Bates of Wales, UK, had a high-performing flock of 32,000 Hy-Line Brown Plus birds.

The flock peaked high and early, with excellent persistency. The flock spent 54 weeks over 90% production (29 of which were 95% or above). Due to the Bates’ excellent management, livability to 77 weeks was 97.52% vs. the breed standard of 95.5%. Total hen-housed eggs were 378, which is 20 above the midrange standard! Egg mass was 1 kg greater than the standard. The flock was very feed efficient for a free range flock, making an egg per 131 g of feed consumed.