Mycotoxins inflict damage poultry, pig production

Mycotoxins hurt feed quality and some can impact production performanceFeed grains contaminated by mycotoxins hurt feed quality and are detrimental to production in poultry and swine. Some key mycotoxins can induce differential impacts on poultry and swine production performance.

It is not a secret that animal feed containing mycotoxins will negatively impact production. During wet years, mycotoxins are very likely to be present in your grain products. Most animal systems are affected by a large dose of a single mycotoxin or a combination of many mycotoxins. This bulletin highlights the damage that mycotoxins can have on the digestive, immune, and reproductive systems of poultry and swine.

Fact 1: Mycotoxin exposure can cause direct damage to the digestive tract.

Intestinal disturbances, regardless of source, are often linked to reduced growth performance and reduced feed efficiency. Trichothecene mycotoxins can induce necrosis in the oral mucosa, esophagus and gastric compartments. Fumonisin mycotoxins often have extended periods of exposure time to the intestinal tissues due to poor absorption. The extended contact contributes to direct cellular damage, resulting in intestinal inflammation and diarrhea. In addition to the direct damage to the intestinal tract, ochratoxins and aflatoxins produce severe damage to the liver, which plays a fundamental role in the digestion and mobilization of nutrients after they are absorbed in the intestine.

Fact 2: Mycotoxin exposure decreases the ability of the digestive tract to digest and absorb nutrients.

In poultry, the intestinal tract is relatively short, making villi the main structures responsible for amplifying intestinal surface area for absorption of nutrients. Deoxynivalenol (DON) and Fusarium mycotoxins can shorten the intestinal villi in broilers and poults. Intestinal secretions and activity of enzymes responsible for the digestion of nutrients can be also affected by some toxins and thus contribute to decreased digestive ability. In swine, the impact of feeding mycotoxins can occur quickly; in one instance, after feeding mycotoxins for just 16 days, growing swine experienced negative effects of mycotoxins in intestinal health and growth performance. These effects were observed to impact growth for up to 6 weeks after mycotoxin contaminated feed was removed from the diet, decreasing average daily weight gain in pigs.

Fact 3: The presence of mycotoxins may render swine and poultry more susceptible to some bacterial pathogens, like E. coli and Salmonella.

This could be secondary to an immunosuppressive effect of mycotoxins. In general, large doses of mycotoxins such as ochratoxin and trichothecenes will lead to lymphocytic depletion in immune organs, meaning reduced immune function overall. Reduced immune function can also occur when contamination of feed occurs from different mycotoxins simultaneously, even if concentrations are below the respective maximum threshold individual mycotoxin. This is due to cooperative activity that occurs when several mycotoxins are fed at the same time. Depression of immune cells occurs along with inflammation on different organs renders several tissues more prone to bacterial and viral contamination. As a rule of thumb, after monogastrics have been consuming feed with contamination levels of mycotoxins, they will be more susceptible to infections and disease.

Fact 4: In swine, reproduction is greatly impacted by exposure to mycotoxins.

Diets contaminated with zearalenone (ZEA), a mycotoxin derived from Fusarium Fungi, are particularly detrimental to reproduction in swine. This is due to the ability of ZEA to specifically bind estrogen receptors. In sows and gilts, this binding induces prolactin secretion, reduces luteinizing hormone and progesterone secretion, alters uterine morphology, ultimately suppressing functional ovulation and heat expression. Because of the interaction with estrogen receptors by ZEA, early term abortions might also be observed. However, the impact of mycotoxins on abortion may vary across herds fed different diets or among those using estrous synchronization protocols.

A buildup of multiple mycotoxins, including DON, can also have an impact on reproduction. Since there are many toxins with different physiological effects, when a combination of them are consumed, the impact on reproduction becomes highly variable. In boars, ZEA exposure reduces serum testosterone, hindering sperm quality. Mycotoxins may also impact fetal development in swine. In one study, diets fed to swine containing high levels of ZEA resulted in reduced fetal and placental weight when exposure occurred up to day 70 of gestation. Reduced placental size and weight is associated with restricted intra-uterine growth, lower birth weights, and reduced growth performance over the lifetime of the pig. In poultry, there are few reported reproductive consequences due to exposure to mycotoxins.

What can you do to reduce mycotoxin load in feeds?

In general, fungi that produce mycotoxins are commonly present in the field, therefore, crops are exposed to them at a very early stage. This means that mycotoxins are commonly present in all crops, and that the concentration of mycotoxins in grain products is the key to understanding the potential impact of mycotoxins on the health and performance of livestock. Weather, especially during the harvesting season, plays a critical role in influencing the production of mycotoxins. In general, moisture and high temperatures encourage mold growth and mycotoxin production. This is why rainy harvesting seasons are related with a higher content of mycotoxins in crops vs drier harvesting seasons.

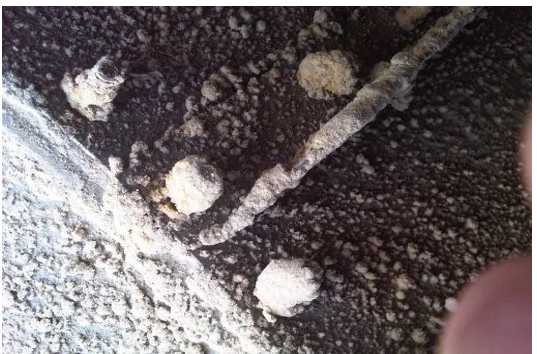

Storage of grain can either introduce mold or encourage mold growth and the consequent production of mycotoxins. Grain left exposed to the elements and feed stored in dirty silos or bins are a primary area for controlling mycotoxins in grain. Metal walls of silos conduct heat during the hottest hours of the day, transferring that heat to the adjacent grain. As the temperature cools, condensation builds inside the silo or bin.

Humidity and heat in the presence of mold contamination on the walls of a dirty silo are the perfect environment for mold growth and mycotoxin production. Concerns with mycotoxin contamination during feed storage is especially relevant in young animals or small herds where feed tends to be held for longer periods of time (greater than 7 days) within bins and silos. Clean storage bins, however, are only part of a system of management for mycotoxin exposure.

Managing mycotoxin exposure should start at harvest by removing heavily contaminated grains when possible. One of the most cost-efficient ways to eliminate mycotoxins is by eliminating heavily contaminated grain. Not all grain is equally contaminated with mycotoxins. Very few grains contain most of the overall contamination affecting a crop. The heavily contaminated grain is considerably lighter than non-contaminated grain and it can be removed with a grain separator that uses air flow to raise and separate very light kernels from the undamaged grain.

Investment for grain processor or feed mill is high to begin with, but savings on the long term are guaranteed. Removing contaminated grains can be aided by being able to identify contaminated grains. To learn how to identify contaminated grains, look for Penn State Extension articles that will help you identify, handle contaminated grains, and use mycotoxin contaminated grains. However, if you are purchasing mixed feed or ground grain, other methods will be needed in order to effectively deal with the mycotoxin load.

If you have purchased grain or feed that is contaminated, dilute the affected grain with uncontaminated, high quality grains. In general, there is a range for most mycotoxins at which they start affecting the animal production in a significant manner. If mycotoxin affected grains must be used, dilution of the affected batches of grain is a cost-effective measure for reducing the impact of mycotoxins on livestock consuming that grain. However multiple sampling and mycotoxin analysis are needed to determine the concentration of mycotoxin in every batch of feed, reducing the practical efficiency of this method for feed manufacturers. As an additional tip, prior to diluting affected raw materials organic acids could be sprayed on them. This will kill most of the fungal contamination and will limit the mycotoxin production once the contaminated material has been diluted.

If mycotoxin contamination is still an issue after attempted dilution of the diet, mycotoxin binders could be another option to reduce the impact of mycotoxins on poultry and swine. In general, non-polar (aflatoxin) mycotoxins are effectively bound by mycotoxin binders. Most of the binders available on the market are really effective for binding this toxin as most clays will do this naturally. Most binders can bind toxins and nutrients at the same time; however, this should not be a concern if binders are only used for a short period of time. If mycotoxin binders need to be utilized over a long period of time, you may want to explore specific, porous surface clays that are especially suitable for toxin binding or formulate your diet with additional vitamins and minerals.

Critical evaluation of mycotoxin binders should be practiced when looking for a binder to utilize on mycotoxins that are not from the aflatoxin family. Some mycotoxin binders on the market that advertise 'added technology' tend to be more expensive than generic products and not adequately tested in live animals. Many of the current tests to demonstrate the efficacy of mycotoxin binders are conducted in vitro (in the absence of animals). Binders tested only in vitro may have been exposed to unrealistic conditions, such as prolonged contact time with the substrate (24 h) or while using pH ranges that do not mimic physiological pH ranges. In nature, the pH of the intestinal tract is variable and the contact time of the toxins with the intestinal mucosa can be short. For example, in chickens, feed enters and leaves the duodenum in 15 minutes or less and most of the ingesta is out of the chicken in 6-9 hours.

In vitro binding ability over a 24 hour period on a constant pH is meaningless. While contact time is longer in swine, binders should offer detailed proof of their claimed technology for charging premium fees. It is also important to note that binders will not bind mycotoxins in dry feed. The process of mycotoxin binding will only start when the animal ingests the feed (binders need an aqueous substrate to bind toxins). Due to this delay, even the most effective binder will not mitigate the initial toxic effect immediately after feed ingestion. Only after a few minutes will dietary binders start binding to mycotoxins, even in the case of utilizing exceptionally effective dietary mycotoxin binders.

In summary, animal production is hindered when livestock are exposed to large amounts of mycotoxins. Mycotoxins cause damage to the intestinal tract, immune and reproductive systems in poultry and swine, respectively. It is important to remember that the damage to the reproductive system in swine may have long lasting effects.

Avoiding the ingestion of mycotoxins by removing affected kernels, diluting contaminated raw materials or feed, or by adding mycotoxin binders. Each method of managing mycotoxin contaminated feed and ingredients presents advantages and disadvantages. Mycotoxin binders are popular and especially effective for aflatoxins, which are easy to control by most commercially available binders. Products that offer ability to bind or deactivate toxins other than aflatoxin should be cautiously evaluated and require further inspection.

Be aware of the impact of mycotoxins on your livestock this year, apply these tips, and others from Penn State Extension, to your feed quality and mycotoxin management plans.