Optimising Management to Combat High Feed Costs

Managing broilers to increase the efficiency of converting feed to saleable meat is key to remaining profitable, writes Dr Chet Wiernusz, nutritionist with Cobb World Technical Support Team.At a time when high feed prices are squeezing profit margins, it is surprising that many of the industry practices and management guidelines are still based more on opinion and trial-and-error than scientific evidence and documented solutions.

With feed representing over 65% of the total production cost, managing broilers to increase the efficiency of converting feed to saleable meat is key to remaining profitable.

Broiler feed conversion is dependent on dietary nutrient concentrations and environment. The energy required for broiler maintenance alone can be greater than 45% of metabolisable energy consumption.

The growing environment has the greatest impact on broiler maintenance and involves factors such as effective temperature, immune status and lighting programs.

These factors are interactive and can be quantified to allow management decisions to enhance production efficiency.

Decisions relating to feed and water, ambient temperature and bird activity and health are of great importance in influencing feed conversion.

Various stress factors have the potential to impair performance, too, including ambient temperature and relative humidity extremes, immunological response and air quality.

Feed and Water Supply

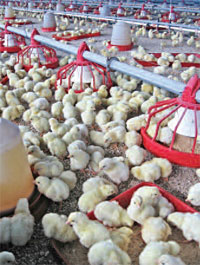

Adequate feed and water at placement and during the first week will ensure proper intake and minimal competition among the chicks.

It is recommended to provide sufficient feeding space for the birds by covering at least 50% of the house with chick paper.

Offer at least 50-65g of feed per chick on the paper, a large volume that will be easily consumed in three to four days.

If chick trays are being used, ensure at least one tray per 100 chicks. The trays must be evenly distributed throughout the house and only removed once the chicks have access to a flooded feed pan. Removal of the feed trays too early is often obvious when 14 day bodyweights are below standard.

Water access is equally important, but with a modern nipple system it is easily achieved. The first water consumed by the chick must be clean. Always implement a water line sanitation program during house cleanout and flush the lines just before placement.

Regular water sanitation and water line cleaning can provide protection against microbial contamination and bio-film buildup. Once established in water lines, bio-films provide a place for detrimental bacteria and viruses to hide from disinfectants.

Products containing 50% hydrogen peroxide, stabilised with silver nitrate, have proven to be outstanding for removing biofilms in water lines.

The bird’s thermoneutral zone is defined as the ambient temperature with minimum heat production (Figure 1).

Since heat production originates from feed intake, it is also the ambient temperature where feed conversion ratio (FCR) is optimum. Under low ambient temperature conditions, heat produced helps maintain body temperature.

However, under high ambient temperature conditions, the bird already has a higher than desired heat load, body temperature is elevated and any additional heat production to compensate for the stress further exacerbates the condition. This occurs as the birds must expend energy, usually as increased respiration, to return the elevated body temperature to normal.

During heat stress the bird’s ability to dissipate heat is reduced, causing an increased reliance on respiratory cooling and an elevated respiration rate.

Unfortunately, in many climates the evaporative cooling system used in many houses only partially compensates for the heat load and body temperature rises.

|

Poultry activity, or behaviour, has not received as much research attention as other areas. Indeed, in our modern production environments there has traditionally been little perceived economic value in understanding or monitoring bird behaviour.

Most of the focus in broiler production has been on genetic progress, strain selection, feeding programs and management systems – with little focus on how the bird’s behaviour responds to such changes.

However, bird activity is the major energy loss between consumed dietary energy and the amount of energy retained as tissue.

Broilers typically spend their time in the following order (from greatest to least) – resting, eating, standing, drinking, preening, walking, pecking and other.

It is common for the combination of eating and resting to account for 60-85% of a broiler’s total activity.

Pelleting and lighting programs have a marked influence on bird activity. Pelleting poultry feeds has long been recognised as a method to enhance bird performance.

Pelleting is known to increase bodyweight, reduce feed wastage and improve feed conversion. Its exact mode of action, however, is the subject of speculation. Work reported by Dr Robert Teeter at Oklahoma State University noted that broilers fed pellets spent less time eating and more time resting than those fed mash.

Consequently, as the percentage of pellets that a bird consumes increases, the amount of time it spends eating decreases (Figure 2).

Broilers respond to pelleted feed by spending less time to eat the same or more feed. The time saved is spent resting, which decreases animal energy expenditure and so leaves more energy available for gain (Figure 3).

Lighting Programs

Lighting programs are a key ingredient for good broiler performance and flock welfare.

Typically they are designed with changes occurring at pre-determined ages and tend to vary according to the final target market weight of the broilers. Beneficial effects of lighting have also been noted for broilers since 1957.

Despite this, broiler lighting programs were predominately 23 hours light: one hour dark until the late 1990s.

Since then, additional hours of dark have been found to benefit broiler production, improving FCR and reducing ascites and leg disorders as well as lowering morbidity. Some consider the evolving role of lighting programs to be more important as genetic improvements provide marketable birds in fewer days.

A proper lighting program will increase liveweight and reduce feed consumption, with reports of improved FCR of 2-7 points common.

The primary energy cost between energy consumption and the metabolic efficiency for energy utilisation above maintenance (~84%) is bird activity.

Lights profoundly impact on bird heat production as placing broilers in the dark reduces this by about 30% within six hours (Table 1).

One standard lighting program will not be successful for all parts of the world. Therefore, the lighting recommendations should be based on local environmental conditions, house type and overall stockman objectives.

Lighting programs inappropriately employed may impair average daily gain (ADG) and compromise flock performance. Careful observations of flock performance, nutrient density and intake are also important in designing lighting programs.

If accurate ADG information can be acquired, a program based on average weight gains is preferred.

It is recommended that 25 lux as measured at chick height, be used during brooding to encourage early weight gains.

Optimum light intensity at floor level should not vary by more than 20%.

After seven days of age, or preferably at 160g bodyweight, light intensities should be diminished gradually to 5-10 lux.

Broiler lighting programs in conjunction with the proper genetics, environment, nutrition and management create the most welfare friendly conditions in addition to improving flock performance.

Energy cost due to immune challenge is included in the maintenance category as it requires energy and nutrient expenditure independently of gain.

The impact of microbial load, infectious diseases, necrotic enteritis and vaccination on poultry performance are well documented throughout the scientific literature. Indisputably, some microbial species are more damaging than others.

Though some view the impact of immunological challenge as being solely defined by specific nutrient and energy need, the impact of feed intake cannot be ignored.

Conclusion

Today’s commercial broiler is the most efficient ever, representing the combined efforts of genetics and management. There is a need to change the way broiler breeders are managed and fed.

There is a wealth of information on nutrition and management of broilers but the industry often lacks basic knowledge of broiler metabolisable energy and the amino acid requirements for optimal productivity.

Though many companies offer feed and bodyweight guidelines for rearing breeders, it seems that much of the industry practices and management guidelines for broilers are based more on circumstantial opinions and trial-and-error than on scientific evidence and documented solutions.

Any increase in bird maintenance need diverts energy away from potential growth, and remember that management decisions can have a positive or negative influence on broiler energy requirements.