Optimising Protein Utilisation in Broiler Feeds – Role of Protease Enzymes

For economic, ecological and animal health/welfare reasons, there is an increasingly important need to improve the utilisation of dietary protein and to minimise nitrogen output, according to Dr Adam Smith of DSM Nutritional Products.Whilst there are various well documented strategies available which can help achieve this, there is still much scope for improvement. One recent innovation which offers potential to improve this situation is the use of protease enzymes specifically selected and developed for use in feed.

What do We Mean by Optimising Protein Utilisation?

Broilers, like all animals, do not require protein per se but rather the component amino acids. The aim, when trying to optimise protein utilisation, should, therefore, be to meet the animal’s requirement for the different amino acids as accurately as possible with the minimum intake of protein. To achieve this, it is important not only to maximise digestibility of protein in feed ingredients, but also to try and ensure the profile of amino acids presented to the animal is as close to requirement as possible.

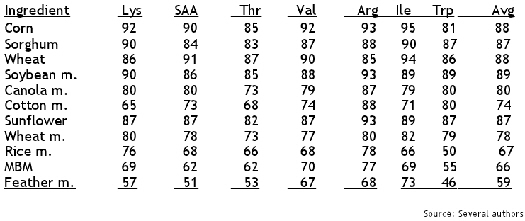

Typically, for conventional feed ingredients, amino acid digestibility averages only 80 to 90 per cent. This means 10 to 20 per cent of all ingested protein is not digested (Figure 1). Instead, it passes to the hind-gut where it is used by micro-organisms inhabiting the lower intestine for their own growth and development, before being excreted.

Of those amino acids absorbed by the broiler, not all are required at similar levels. Rather, there is an ‘ideal’ amino acid profile for a particular production target. In practice, it is not possible to meet such ‘ideal’ amino acid profiles fully with the ingredients available. Consequently, to ensure the requirements for the most limiting amino acid are met, others must be provided in excess. As excesses of amino acids must be deaminated and converted to uric acid, which is an expensive process in terms of energy and animal performance, they should be minimised by supplying amino acids as closely to the ideal profile as possible.

Why Optimise Protein Utilisation?

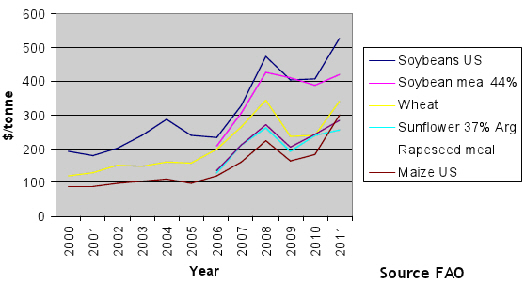

Probably, the main reason is economic. Protein-containing raw material prices have shown a sustained upward trend over the last few years (Figure 2) and it is the general consensus that prices will continue to increase in the future. Ecological and sustainability issues are also increasingly important. Litter containing high levels of nitrogen, when spread onto fields, can become an environmental hazard. Nitrogen, along with phosphorus, remains one of the two dietary nutrients of most concern to the environment in developed countries, and for which increasingly stringent regulations on disposal are being enforced.

As well as economic and ecological reasons, there are also production, welfare and food safety benefits for optimising the utilisation of protein. When excess protein must be excreted as uric acid, birds will drink more water, in turn, leading to increased litter moisture. Wet litter has been linked to increased incidence of pododermatitis, as well as hock burns and skin blisters. In addition, part of the excreted nitrogen is converted into ammonia which is released into the atmosphere, reducing air quality and increasing incidence of respiratory disease. Finally, amino acids which are not digested and pass to the hind-gut favour the growth of pathogenic micro-organisms such as Campylobacter and Salmonella.

Established Strategies

There are various well documented and practised approaches to optimising protein utilisation in broiler feeds such as:

- selection of feedstuffs with high amino acid digestibility

- control of processing conditions which impact negatively on amino acid availability

- the use of synthetic amino acids

- diet formulation on a ‘digestible’ as opposed to a ‘total’ amino acid basis, and

- use of the ideal protein concept.

Together, these contribute towards the formulation of diets with a higher amino acid digestibility and which more closely meet the ‘ideal’ amino acid profile of the broiler. There is, however, still significant scope to improve this situation further and the recent launch of effective protease enzymes offer one such way.

Development of Proteases

There have been various attempts in the past to develop protease enzymes to help improve digestibility of amino acids in feed ingredients. However, until recently, most efforts have given at best inconsistent results under commercial conditions. More recently, Ronozyme® ProAct, a protease which has been specifically selected for use in feed, has been launched. Such innovation has provided an additional tool to further optimise protein utilisation by consistently improving the digestibility of amino acids in a wide range of natural feed ingredients.

For a protease to improve digestibility of amino acids from feed ingredients successfully, it should, like any other enzyme, be selected and developed with that specific use in mind. Ronozyme ProAct is produced from a genetically modified strain of Bacillus lichenoformis. The selection process considered the essential criteria needed for success in feed. Factors such as ability to increase digestibility of many different feed proteins, the ability to complement the endogenous protease enzymes, activity after exposure to low pH conditions of the gizzard and proventriculus, and stability during feed processing were all taken into account.

What Are the Benefits?

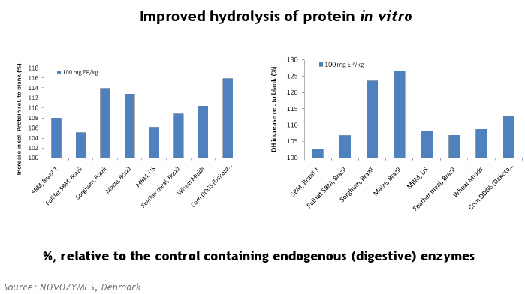

Figure 3 shows the additional protein solubility and digestibility (measured as degree of hydrolysis – DH) achieved with Ronozyme ProAct relative to a control containing only endogenous digestive enzymes in an in-vitro monogastric digestion model. This clearly shows that a protease such as Ronozyme ProAct has the potential to improve both solubility and digestibility of protein in a wide range of ingredient sources in vitro.

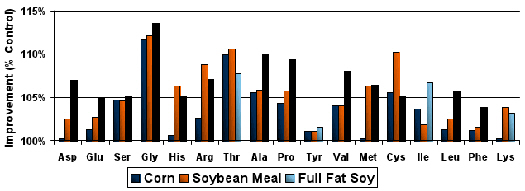

In vivo, amino acid digestibility trials with broilers fed both complete feeds and semi-synthetic diets with high levels of individual raw materials, have also shown significant improvements in amino acid digestibility when Ronozyme ProAct is added (Figure 4).

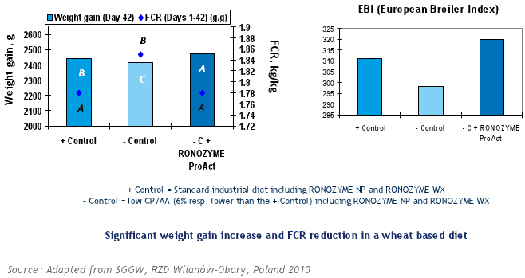

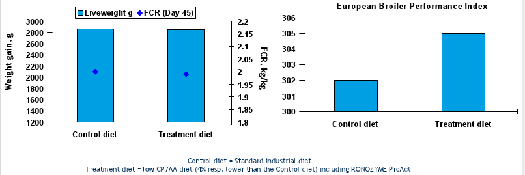

Although the response for each amino acid is different, the observed improvement in digestibility is typically between three and eight per cent. By upgrading raw materials appropriately, it is possible to formulate lower protein diets which at least maintain animal performance (Figure 5).

Such scientific studies are confirmed in commercial broiler trials. Figure 6 shows the results of a trial in broilers grown to 45 days and fed either maize, wheat and soybean meal-based diets formulated to the industry standard or with four per cent of the digestible amino acid content replaced with Ronozyme ProAct. Average savings of €4 per tonne of feed were achieved across the different phases with Ronozyme ProAct whilst performance on both diets was similar. Savings of €1 to €5 per tonne of feed are frequently seen as a consequence of the improved amino acid digestibility without any loss in bird performance. The resulting lower protein diets also lower nitrogen excretion and improve litter quality.

Conclusion

In conclusion, there are a number of increasingly important economic, environmental and animal husbandry reasons for optimising protein utilisation. Although there are various well practised approaches to help achieve this, there is still scope for improvement.

One recent innovation that can improve this situation is the use of protease enzymes, specifically selected and developed for use in feed, such as Ronozyme ProAct. Such products improve the digestibility of amino acids in a wide range of natural feed ingredients, allowing lower protein diets to be formulated without loss in animal performance. Not only does such use provide cost savings for the user but also reduces nitrogen excretion, offering advantages for the environment both inside and outside of the poultry house.

December 2011