Preparing poultry houses for extended out times

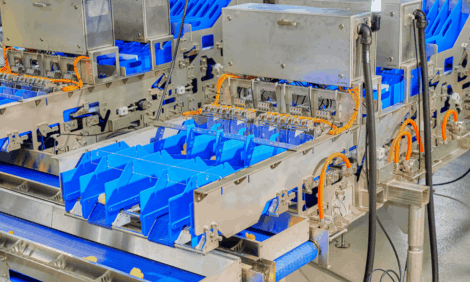

1. Get all the feed out!

It may not be easy, but this is the number one item to concern yourself with when preparing a house for extended downtimes. Feed left in the lines or feed bins will attract mice and rats, which can grow to infestations that will plug the lines and prevent them from running on startup. Also, feed left in the lines can mold and harden, resulting in augers breaking or motors overheating and stalling when started.

2. Drain the water.

Shut off and drain all water lines, including drinkers, foggers, and cool cells. After draining and cleaning evaporative systems, remove pumps and move to inside storage. Remove medicators from their plumbing, allowing water to drain. Disassemble medicator and soak for 24 hours in soapy water to loosen any mineral buildup. Flush parts and reassemble.

3. Grease and oil.

Put a shot of grease in every zerk on fans, curtain machines, corner wheels, etc. This lubrication is especially important on older bearings or shafts with more wear.

4. Litter.

The best method to reduce insect presence and eliminate ammonia from the house is to remove all the existing litter. Complete removal may not be practical because of the additional cost for rebedding or integrator preference. If that is the case, the best practice is to decake and prepare litter according to your normal procedures for the next flock. Just keep in mind if you keep older litter in the house ammonia can continue to be released and ventilation is important to remove it.

5. Gas Supply.

Turn the gas supply off to the buildings, clean dust and debris from heaters. Consider covering brooders with plastic or brooder covers to prevent dust accumulation.

6. Darkling beetles.

Treat immediately after depopulating. Spray the outside of the house to prevent migration to other parts of the farm. Pay special attention to the building walls, areas where feed and drinker lines are/were, and even your attic, especially if removing the litter. Reapply treatments monthly or if you notice increased activity.

7. Rodent Control.

The first step to rodent control is to remove all feed from the building. Remove all cardboard boxes, coveralls, and clutter from the office that mice or rats could use for nesting. Fill the bait stations and continue to monitor for rodent activity. Always remember to rotate the active ingredient in your rat baits at least every six months.

Active maintenance.

After prepping and closing down the building, controlling the moisture and ammonia levels takes priority. Many controllers have an empty building setting allowing you to set the minimum ventilation rates. Leaving the controller functioning and power on also allows you to receive any alarm alerts. Now is also a good time to add surge protection to the electrical system if not already installed. The surge protector would prevent a lighting strike, leaving your controller inoperable without your knowledge, creating an unexpected problem on startup.

An empty feed system with the bearings greased, gear head oil levels intact, and the building's ammonia under control should be fine if inactive for 60 days or less. Much past this time frame, the system would benefit from being lowered to the floor and reassembled. Check auger gear head oil levels and top if low. The oil will settle to the bottom gear head and may leak from seals during periods of inactivity. Running the system will loosen any rust, activate the electrical contacts, and point out any problems that have developed which you can then address before placing your next flock.

The same thing holds true for the full ventilation system. Power up the system to run the fans and cycle the curtain machines and vent actuators. Activate sidewall and cool cell curtains up and down, paying attention to any curtain bunches that might harbor rodents or insects.

By sticking to a regular inspection schedule during long out periods between flocks will mean your houses will be ready when it’s time for your next bird placement.