Strategies to Control Salmonella in Poultry

A high level of biosecurity (cleaning and disinfection) in poultry and food processing plants is important to avoid disease outbreaks, possible slaughter of the total flock and related profit losses, according to Vatche Sagherian for CID Lines.Poultry are considered one of the most important Salmonella reservoirs, it has been public health concern over the past 100 years and continues to be a major foodborne pathogen affecting humans.

Strategies to prevent transmission of salmonella to humans should focus on the whole production chain of broiler meat and on the subsequent storage and handling of meat – from 'Farm to Fork'.

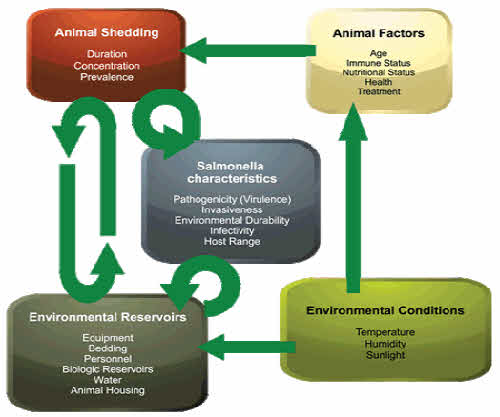

Factors Affecting Salmonella Prevalence

Introduction of Salmonella to the Broiler Farm

- Vehicles

- People

- Clothing

- Footwear

- Equipment

- Utensils

- Water

- Feed

- Feathers

- Carcass of dead birds

- Litter

- Insects

- Rodents

- Wild birds

- Pets

Salmonella control strategies in broilers fall into three main groups:

- pre-harvest phase (breeding farms and broiler farms)

- harvest phase (catching and transport)

- post harvest phase (at the slaughter house, at retail and in the consumer’s kitchen or restaurants)

Salmonella Control in the Production Phase (Pre-Harvest)

Biosecurity and hygiene measures

General hygienic and biosecurity measures should be part of the overall management plan of poultry producing integrators and companies. These measures are of utmost importance to control infections and all other measures lose their efficacy when the overall biosecurity plan is not functioning.

- Introducing salmonella-free birds is the most important starting point to prevent infections

- Incoming birds should be of good health status

- Restricted access is an important issue

- Shower and changing room facilities for workers and visitors

- Limit the entry of non-essential visitors

Only essential visitors, wearing protective clothing (coveralls, gloves, mask, etc) and disinfected boots should be allowed on-farm.

Simple measures such as foot baths, wheel baths, hand hygiene and minimising movement between different animal houses need to be implemented properly.

Buildings, surfaces, fans, cooling pads and equipments should be cleaned and disinfected properly.

Establish clear zone, free from vegetation, around building to discourage rodent and insect traffic in the building

In an overall management plan, cleaning and disinfection after each production cycle must be routinely performed as described below (CID Lines Sanitation Programme)

Five Principles for Salmonella Control

- Salmonella-free day-old-chicks (parent stock, hatchery, transport)

Salmonella is transmitted vertically (via the egg from parent to chick), thus an obvious starting point for any Salmonella control strategy is to ensure poultry breeding flocks are kept Salmonella-free.

- Rearing chicks in Salmonella-free environment

- All-in/all-out management

- Vector control: wild birds, flies and rodents

- Visitors

- Good cleaning and disinfection protocol

- Salmonella free water and feed

- Pelleted feed contains 10 times less Salmonella than non-pelleted feed (thanks to heat treatment)

- Antibiotics: can cause resistance Salmonella, affect the resistance of the animal against colonisation

- Addition of organic acids enhance Salmonella destruction

- Drinking water sanitizer

- Regular monitoring of total production chain

According European legislation, the production chain is regular monitored by sampling of poultry flocks

- Immediate action when Salmonella is detected

- Determination of the origin of the infection.

- Movement of poultry flocks at the end of the production cycle should only be allowed for slaughter or destruction.

- Poultry litter/feces and other potentially contaminated farm waste should be disposed of in a safe manner.

- Particular care should be taken in cleaning and disinfection of the poultry house and equipment.

- Before restocking the facility, a bacteriological examination should be carried out.

- Adequate time should be allowed between flocks if previous flock was Salmonella-positive.

- Buildings, surfaces and equipment should be cleaned and disinfected properly.

CID Lines Sanitation Programme

- Dry cleaning

- Soak with water, remove most of dirt

- Clean water system with CID 2000

- Clean the:

- Ventilation fans, air inlets and cooling Pads

- Ceilings

- Outside water system and out/inside of feeding system

- Floors and walls

- Sanitary and storage rooms

- Environment of the poultry house including silos

With CID Lines' alkaline foaming detergents at the correct dilution and contact time (see label).

- Rinse with water and let it dry

- Disinfect with VIROCID (Spray, foam or fog)

There are a lot of critical points that often forgotten during the cleaning process:

- Lights

- Heaters

- Water tubes

- Cracks in the floors

Salmonella Control During Transport (Harvest)

Feed should be withdrawn from the birds between eight and 12 hours before the slaughter time to reduce the amount of defecation and contamination of the carcass. Transpiration of a salmonella-positive flock leads to contamination of the crates and containers. Each time, after unloading the flock; crates, containers, vehicles have to be cleaned and disinfected.

Clean with CID Lines' alkaline detergents (non-foaming for tunnel washers; foaming for manual cleaning with a HP cleaner and foam lance). Rinse with water and disinfect with VIROCID.

Salmonella Control Practices During Slaughter and Processing (Post-Harvest)

Slaughter house is divided into two main zones:

- Dirty zone where slaughtering, bleeding, scalding, defeathering and evisceration takes place

- Clean Zone where all procedures are carried out at low temperatures and under strict hygiene controls

Defeathering, evisceration, scalding and chilling are critical control points at processing stages where cross-contamination may occur.

- Salmonella-positive birds during defeathering and evisceration process contaminate the carcass, the slaughter equipment and cross- contaminate the carcasses of subsequently slaughtered flocks.

- Single counter-flow water movement and maintaining the pH of scalder bath water below 6.5 by adding CID Lines' water acidifier will reduce microbial contamination both of the birds and the scalding water.

- Scalder water temperature must be 51-53 °C.

- Control of chilling parameters: air temperature, air movement, relative humidity and filtering air can reduce Salmonella or other microbial growth.

- Using peracetic acid in the water chiller with exact dosage and contact time reduces Salmonella and other microbial contamination on the skin.

A control measure to reduce or eliminate cross-contamination is logistic slaughter; in other words, Salmonella-negative flocks should be slaughtered before Salmonella-positive flocks.

Slaughter equipment and especially killer blade, scalding tanks, plucker and defeathering; must be cleaned with CID Lines' alkaline chlorinated or non-chlorinated foaming detergents, rinse with water and disinfect with CID Lines' food-grade disinfectants.

Conclusion

High level of biosecurity (cleaning and disinfection) will help to reduce the incidence of diseases in poultry farms and food processing plants; while poor levels of biosecurity, can cause disease outbreaks where total slaughtering of the whole flock will be a must.

So, when biosecurity measures are taken, the risk of Salmonella or other microorganisms reaching humans will be reduced to minimum.

During the live production phase, hygienic measures and general farm management strategies are equally important.

During slaughter and processing phases, hygienic measures and logistic slaughtering are important tools to Salmonella and other foodborne microorganisms.

May 2011