The future of animal production lies in its environmental approach

Is your manure management a cost or a source of revenue?Over the past decades, the environmental impact of livestock production and manure management has been controlled by stricter regulations for manure storage and spreading. Nevertheless, the intensification of livestock production has led to even larger herds on industrial-scale operations that produce large quantities of manure at centralised locations or regions.

As intensive livestock farming is being placed under increasing pressure to minimise the environmental impact of its operations, several methods for manure treatment have been evaluated while improving nutrient resource use. More importantly, they’re usually subjected to national subsidies which prevent them from being profitable in the long term. There are also numerous references to fines and penalties for entities that release bad odours into urban areas or pollute natural resources. Due to the intensification and the continued proliferation of these issues and others, policies for the closure of livestock farms are beginning to be implemented, namely in the Netherlands, where the government subsidized the closure of 400 farms.

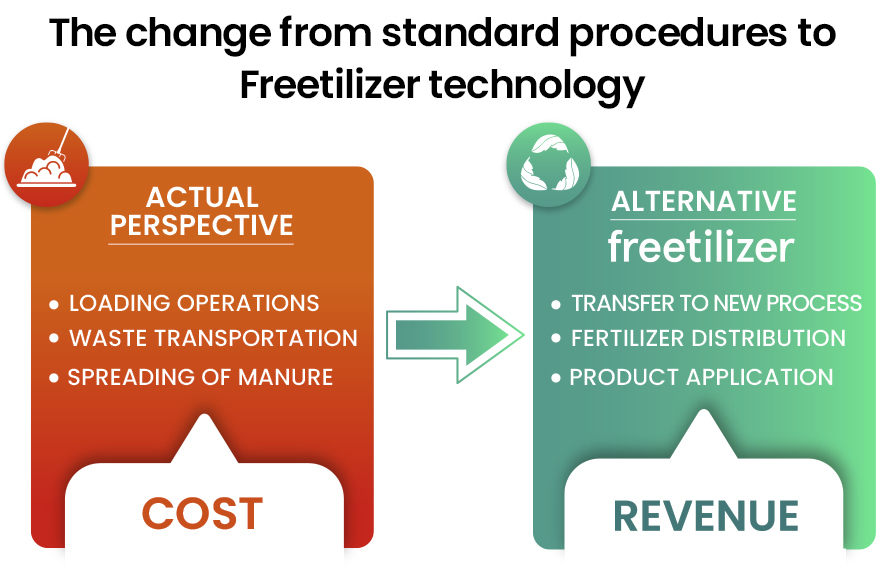

The three key points that influence the cost of manure management are loading, transportation and spreading. Normally each activity requires its own specialized equipment and can constrain the use of the manure. Loading is best done when animals are not present and thus limited to specific time periods. Spreading requires proper soil and plant conditions that often cannot be found locally. Thus, transportation may be necessary. It can be quite costly and time consuming, depending on the distance travelled and the amount of water hauled in the manure.

Freetilizer is an innovative technology with a pending patent that creates new value for organic waste and by‐products from the primary sector, transforming them into organic fertilizers in less than 24 hours. The entire process is energy efficient, fast, compact and utilizes all resources with a zero‐waste approach.

The loading operations can be easily integrated between wastewater lagoons and the Freetilizer reactor by automatic pumping systems. Then a hydrolysis is executed by applying specific enzymes in a reactor with controlled agitation, pH and temperature. The organic waste is digested, promoting an increase in the bioavailability of nutrients. The procedure ends with an efficient drying step, using a vacuum drying process that enables water evaporation at lower temperatures which guarantees nutrient quality preservation and results in the formation of a stabilized product.

The advantages over a traditional composting process are significant. By acting quickly in small spaces and avoiding the formation greenhouse gases, Freetilizer presents itself as an alternative for the production of organic fertilizers that assists with crop and pasture growth and development. Freetilizer offers a solution that not only eliminates bad odours, immaturation issues and nutritional imbalances but it also allows the simultaneous production of a solid and a liquid fertilizer, creating the opportunity to enter the organic fertilizer market with a wide range of options and possibilities. With this approach, transportation becomes part of the fertilizer business and spreading is the responsibility of the farmer.

As we know, many poultry owners must pay waste treatment companies to manage chicken manure and litter, and larger facility owners may need to invest in their own treatment equipment to comply with regulations.

Our first principle is to leave the world better than we found it, and Freetilizer technology is one of the best ways to do this.

We are looking forward to your contact. Mail to: [email protected]