Ventilation principles to achieve optimum bird welfare

Ventilation refers to the process by which fresh, clean (normally exterior) air is intentionally introduced and circulated in a poultry house, while stale air is removed. It supplies fresh air that is essential to sustain life and maximise bird performance and comfort. Properly ventilating a house removes excess heat, moisture, odours and, at the same time, controls temperature, humidity and air movement.This article is based on Glenn’s discussions during the recent UK Broiler Roadshows.

Good stockmanship - staying in tune with bird needs

Skilful stockmanship is key to maximising bird performance and welfare. It is important to spend time in the poultry house observing the birds, using your senses - hearing, smell, touch, sight and taste - and responding to signals. Observing the birds and being able to interpret behavioural changes in the flock makes it easier to adjust settings in the house environmental control system.

Optimal operation of a ventilation system depends on a number of factors including control systems and environmental monitoring equipment. The environmental conditions in the house are determined by the controller settings. The stockman’s skills and observations of bird behaviour should dictate controller settings; controller settings should not determine bird behaviour. Ensure that you regularly check the ventilation system settings and monitor bird activity after an adjustment.

Looking after bird comfort and air quality

We ventilate to create an air exchange, control moisture levels (relative humidity (RH)), supply oxygen, remove harmful gases (CO₂, CO, NH₃) and maintain good air quality. Always ventilate to achieve and maintain bird comfort and air quality.

Good air quality can be defined as:

- Oxygen > 19,6%

- Carbon dioxide < 3 000ppm

- Carbon monoxide < 10 ppm

- Ammonia < 10 ppm

At times where minimum ventilation is used the stockman must use ventilation system settings which maintain air quality, litter and the required house temperature with minimal air movement at bird level. The purpose of minimum ventilation (often achieved through running the fans on a cycle timer) is to bring fresh air into the house and exhaust any stale air (to remove excess moisture and prevent the build-up of harmful gases), while maintaining the required in-house air temperature. Minimum ventilation can be used during winter and summer and at any stage of the production cycle. It is most commonly used during brooding and cool weather, and operates at or below the set point temperature, regardless of outside temperature.

The age and quality of house construction, as well as sealing of doors and vents, can significantly influence the efficiency of a ventilation system. Some of the problems encountered with poorly-sealed houses can be cold floors due to cold air leakage, drafts onto the birds resulting from difficulties of maintaining temperature and challenges with ventilating effectively in winter. Uncontrolled air leakage onto ventilation system sensors can result in incorrect operation of fans, heaters and, consequently, air flow. This can, in turn, bring with it poor consistency of air quality and bird performance, uniformity and welfare; not to mention higher heating costs.

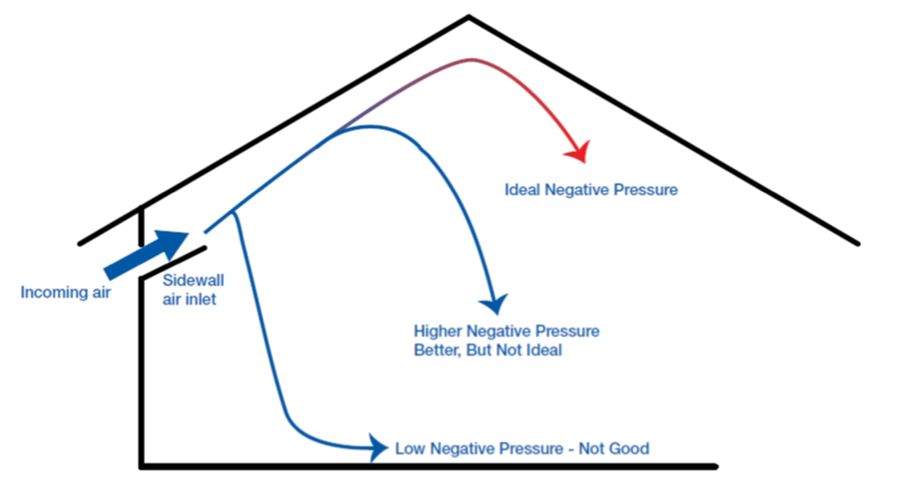

Managing inlet air flow

There are three requirements to optimize air flow:

- Ideal inlet opening (3-4 cm)

- Differential pressure

- Air direction

For a given pressure, air flow will vary depending on the size of the inlet opening. ”Ideal” air flow comes from the right combination of (opening) + (pressure) + (direction). The correct inlet setting will help the incoming air to flow to the peak of the roof where it can mix with the warm air.

Key Points

- Adjustment of ventilation system in response to bird behaviour.

- Quality of stockmanship.

- Correct minimum ventilation settings.

- Control of air flow.

- Sealing of house doors and vents.