News archive

News archive

Hatchery Talks

Hatchery Talks

About Pas Reform

Read more...

Latest news

After three years of intensive research and development, Pas Reform is introducing SmartProTM - its latest and most advanced development for modular, single-stage incubation to date: a solution that enables Circadian IncubationTM.

The modern hatchery manager’s goal is to produce large numbers of uniform, robust day old chicks. Robustness is a health criterion, originating in the embryonic life stage of the chicken – and correlating directly with the performance and resistance of individual chicks under differing farm conditions.

Detailed research has shown that robustness can be achieved by stimulating the embryo with a specific trigger, i.e. stimulation by heat or cold, during critical periods of the incubation process. This causes so-called ‘embryonic imprinting’ on a physiological level, to produce a chicken that will thrive in its farm environment.

Such daily short-term thermo-conditioning is at the heart of Circadian IncubationTM – and known to improve hatchability, for long-lasting effects that include 1-2% increase in final body weight and 1-2 points better feed conversion rates. Batches of uniform, robust day old chicks also deliver uniformity at slaughter age, thereby improving processing yields, efficiency and performance throughout the entire production chain. To support the use of Circadian IncubationTM, the incubator must deliver precise climate control. To achieve truly homogeneous temperature distribution, the challenge is to exchange energy, CO2/O2 and moisture – without affecting temperature uniformity around the eggs.

To meet this exacting requirement, Pas Reform’s SmartProTM uniquely combines three critical features1: modular design, a new VortexTM-based airflow principle and Adaptive Metabolic FeedbackTM.

1 Patent Pending with Worldwide Intellectual Property Rights

Modular design: precise control

- Modular setter and hatcher design enables the precise control of temperature, humidity, O2 and CO2 in large incubators.

- Separate heating, cooling, humidification and ventilation systems in each module of 19,200 eggs provide a homogeneous environment.

- Modular, precise ambient control for larger hatchers comprising up to six modules.

- Integrated heating & cooling system (setter) and SurroundCoolingTM (hatcher) in each section of the incubator, for optimum energy transmission, fast, even warm-up to set temperature and maximum, future-proof cooling capacity.

- Modular design of both setter and hatcher uniquely enables the incubation of eggs from different flocks and different ages in the same machine, without losing performance and results.

VortexTM for complete temperature homogeneity

- Tested and proven as the most effective method of exchanging energy, CO2/O2 and moisture in the incubator.

- Generates multiple, controlled vortices in the wake of the air pump blade, exchanging energy, CO2/O2 and moisture without affecting the incubator’s homogeneous temperature.

- Inlet air is channeled along the side of the setter trolleys, to prevent ambient air making direct contact with the eggs.

- Mixing zone assures complete air temperature homogeneity before air is drawn over the eggs.

- Mixed air vortices flow in parallel with the turning direction of setter trolleys, ensuring that air direction along the eggs changes constantly, for unique, homogeneous egg shell temperature.

AMF™: creating an adaptive environment

- AMF™ software delivers precise, adaptive control over humidity and CO2 during the incubation process – according to the time-varying metabolism of a specific batch of embryos.

- Unparalleled functionality incorporated into one central operator console. Fully integrated sensor box includes high precision electronic humidity and CO2 control.

- Custom controlled relative humidity set points for variable egg weight loss at each stage of embryonic development.

- Prevents excessive inlet of (dry and cold) fresh air for maximum temperature homogeneity.

- Additional, integrated modules include SmartWatch™ - automatically registers and minimizes the hatch window; ESM™ Energy Saving Module - for fully programmable Vortex™ RPM; SmartTransfer™ module - for programmable turning intervals during transfer; PID control – with set points per section and fully adjustable turning programmes.

Thoughtful engineering. Maximum user friendliness

- SmartTouch™ multi-language user interface design, makes operation simple and easily accessible to operators of all skill levels – from experienced hatchery managers with specific control needs, to fully automated hatcheries.

- Large, high-contrast, high resolution 10.4 inch colour LCD screen with Projective Capacitive Touch Screen technology (PCT) and ergonomic user interface viewing angle.

- Highly manoeuvrable trolley, with two swivel wheels and ergonomically designed handle bar for easy loading / unloading of incubator.

- Large inspection window provides full view of entire machine interior for thorough physical inspection, plus comprehensive user interface and record keeping – all from outside the incubator.

- Maximum use of maintenance free components, including high temperature bearings, long-life lubricants, low friction motors and toothed V-belt.

Smart, clean and protected

- Modular hatcher control prevents cross contamination from older to younger batches, because eggs of different ages need not be mixed.

- Hatcher baskets incorporate Microban® technology for the most effective, continuous antibacterial protection. Patented antimicrobial agent penetrates the cell wall of unwelcome micro-organisms on contact, disrupting normal cell function to prevent the multiplication and spread of bacteria.

- SurroundCooling™ – integrated cooling pipes inside smooth-walled ‘food safe’ aluminium hatcher wall panels significantly improve the effectiveness of cleaning, minimize the risk of cross contamination and greatly reduce cleaning time.

- Securely placed and compartmentalized sensors in central operating console allow for high pressure cleaning without risking damage to sensors.

- All surfaces, fixings and finishes are designed to resist the ingress of moisture and bacteria, preventing the creation of dirt traps.

Eco-friendly, cost-efficient incubation

- ESM™ Energy Saving module makes the RPM of the Vortex™ air pump fully programmable – derived from embryonic metabolism rates – to reduce energy consumption by more than 60% in specific phases of embryonic development.

- AMF™ guards against unnecessary or excessive ventilation.

- Vortex™ air pump blades and high-efficiency motors prevent energy loss by optimising energy exchange in the incubator.

- Smart PID control delivers greatest accuracy to date in predicting heating and cooling for each incubator section, to avoid expensive overshoots.

- Fully sealed cabinet, including airtight 3-lock door system and seamless ‘Hotmelt’ panels with maximum insulation value, designed to prevent energy leakage.

| Type | SmartSetPro™ 115 |

SmartSetPro™ 77 |

SmartSetPro™ 57 |

SmartSetPro™ 38 |

SmartSetPro™ 19 |

|

| Capacity hen eggs | 115,200 | 76,800 | 57,600 | 38,400 | 19,200 | |

| Capacity duck eggs | 84,672 | 56,448 | 42,336 | 28,224 | 14,112 | |

| Capacity turkey eggs | - | - | - | 28,224 | 14,112 | |

| Height (+height of motor) (mm) | 2459 (+300) | |||||

| Height including louvre (mm) | 2978 | |||||

| Width (mm) | 4184 | 4184 | 2344 | 4184 or 2344 | 2344 | |

| Depth (+central operating console) (mm) | 7276 (+72) | 4938 (+72) | 7276 (+72) | 2600 (+72) or 4938 (+72) | 2600 (+72) | |

| Number of setter trolley(mm) | 24 | 16 | 12 | 8 | 4 | |

| Height of setter trolley (mm) | 2109 | |||||

| Number of (150 hen eggs) | 768 | 512 | 384 | 256 | 128 | |

| Number of setter trays (126 duck/turkey eggs) | 672 | 448 | 336 | 224 | 112 | |

| Setter tray dimensions | 507 x 733 | |||||

| Modular Design | Heating, cooling, humidification and ventilation systems in each incubation sect | |||||

| Number of incubation sections | 6 | 4 | 3 | 2 | 1 | |

| Number of temperature sensors | 6 | 4 | 3 | 2 | 1 | |

| Heating | Integrated heating, warm water radiator or electrical heating in each incubator section | |||||

| Cooling | Water cooling system with 34 vertical, parallel coils in each incubator section | |||||

| Humidification | Spray nozzle in each incubator section (humidity roller optional) | |||||

| Ventilation | Vortex™ air pump system in each incubation section | |||||

| Set points per section | Separate temperature set points for each section of 19,200 eggs | |||||

| Incubator control |

SmartTouch™ user interface | |||||

| Display | High-contrast, 10.4 inch colour LCD screen with Projective Capacitive Touch screen technology (PCT) | |||||

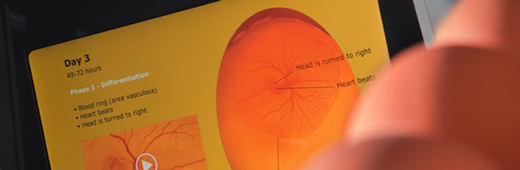

| Embryonic reference | Detailed Academy info on the current status of embryonic development | |||||

| Performance testing module | To run a performance check on incubators before starting a new incubation cycle | |||||

| Pre-heating module | Full programming for pre-heating time, temperature and ventilation | |||||

| Turning programmes | Fully adjustable turning programmes: frequency of turning, start/stop timing, 2 or 3 auto-turning positions | |||||

| SmartTransfer™ module | Provides programmable turning intervals during egg transfer | |||||

| AMF™ (Optional) |

Adaptive Metabolic Feedback™, including fully integrated sensor box, with high precision electronic humidity and CO2 control | |||||

| ESM™ (Optional) | Energy Saving Module, for fully programmable RPM of the Vortex™ | |||||

| SmartCenter™ (Optional) | Hatchery Information System | |||||

| Microban® (Optional) | Antibacterial protection in setter tray | |||||

| Housing | Fully sealed cabinet; robust, easy-to-clean construction with mainly stainless steel interior; extruded, anodised aluminium profiles for maximum stability and ease of installation; seamless ‘Hotmelt’ panels with maximum insulation value; 3-lock door system, includes solid hinges, airtight sealing rubbers and solid door handles | |||||

| Title | SmartHatchPro™ 4 |

SmartHatchPro™ 5 |

||||

| Capacity hen eggs | 19,200 | 24,000 | ||||

| Capacity duck eggs | 14,112 | 17,640 | ||||

| Capacity turkey eggs | 14,112 | 17,640 | ||||

| Height (+ height of motor) mm | 2459 (+300) | |||||

| Height including louvre (mm) | 2978 | |||||

| Width (mm) | 2574 | 3184 | ||||

| Depth (+ central operating console) mm | 2213 (+72) | |||||

| Number of hatcher dolleys | 4 | 5 | ||||

| Number of hatcher baskets | 128 | 160 | ||||

| Modular design | Up to six modules with a capacity of 115,200/144,000 hen eggs | |||||

| Heating | Electrical heating | |||||

| Cooling | SurroundCooling™: 12 parallel water cooling circuits, incorporated in aluminium cabinet walls | |||||

| Humidification | Spray nozzle or humidity roller | |||||

| Incubator |

SmartTouch™, including multiple machine control | |||||

| Display | High-contrast, 10.4 inch colour LCD screen with Projective Capacitive Touch screen technology (PCT) | |||||

| Embryonic reference | Detailed Academy info on the current status of embryonic development | |||||

| Microban® | Antibacterial protection in hatcher basket | |||||

| Performance testing module | To run a performance check on incubators before starting a new incubation cycle | |||||

| SmartWatch™ (Optional) | Hatch window module, including fully integrated sensor box, with high precision electronic humidity and CO2 control | |||||

| SmartCenter™ (Optional) | Hatchery Information System | |||||

| Housing | Fully sealed cabinet; robust, easy-to-clean construction with extruded, anodized aluminum profiles for maximum stability and ease of installation; smooth-walled ‘food-safe’ aluminium inner walls; seamless ‘Hotmelt’ panels with maximum insulation value; 3-lock door system, includes solid hinges, airtight sealing rubbers and solid door handles | |||||