Cobb has a long-standing commitment to animal welfare. We are dedicated to the health and well-being of the chickens that we breed, raise and distribute worldwide. To achieve this goal, we have clear standards and expectations for animal handling and care at our farms and hatcheries, and we work with many researchers and poultry experts to continuously advance poultry health and poultry well-being.

We care about chickens. We are constantly striving to make improvements in animal welfare to benefit the chickens we raise and produce for our global customers. Our farms, hatcheries and feed mills are located in many different areas of the world. These photos will give you a bird’s eye view of our poultry farms and hatcheries, and will also provide you with a visual perspective of how Cobb Cares for our chickens on a daily basis.

Farms

Our breeding chickens are raised on farms located in rural areas. To keep chickens healthy, strict biosecurity requirements are essential to reduce the introduction of disease. These external biosecurity requirements include: fences and gates to exclude livestock entry, secure chicken houses to avoid wild bird or rodent entry, and a shower building for all personnel entering the farm.

Breeding chickens start their life at a rearing farm and remain on this farm for approximately 20 weeks. At the rearing farm, males and females are raised separately so that their weight, uniformity and health can be carefully monitored as they grow. As part of our Cobb Cares expectation, our farmers provide daily care for the flocks and utilize precise lighting, nutrition, temperature and ventilation programs so that the chickens can grow, develop and mature correctly. Rearing flocks also receive specific vaccines to boost their immune status for their long-term health and well-being. After 20 weeks of age, breeding chickens are moved to the laying farm where female breeding chickens (hens) are placed with male breeding chickens (roosters) to produce fertile hatching eggs. On a daily basis, farmers provide feed, water, lighting and ventilation to meet the needs of the laying flock. These daily Cobb Cares checks also allow farm staff to assess the health and behavior of their birds as they walk throughout the laying flock and to proactively evaluate any birds that don’t meet Cobb quality standards. Farm staff also collect the fertile hatching eggs several times during the day and prepare the eggs for shipment to the hatchery.

Hatcheries

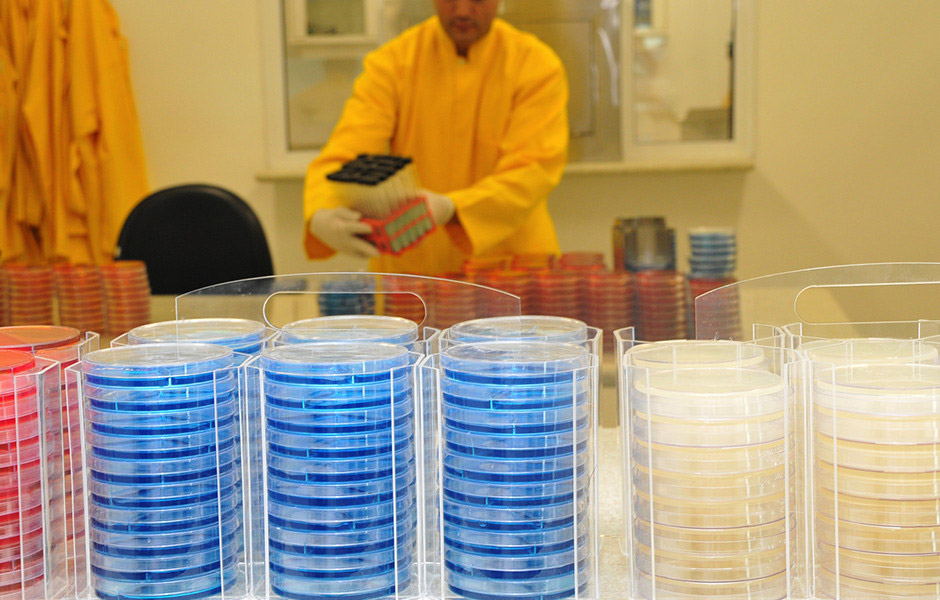

Fertile chicken eggs are transported from the laying farms to the Cobb Hatchery where they begin the 21 day incubation period. During the first 18 days of the incubation period, eggs are incubated with precise temperatures, humidity, ventilation, and regular turning to optimize the development of the chicken embryo. At approximately 18 to 19 days of incubation, a vaccine is administered in-ovo (in the egg) to help stimulate the embryo’s immunity before the chick hatches. After this precise vaccination, fertile eggs are then transferred to separate temperature-controlled rooms where the chicks will hatch and be ready to begin their next steps in the hatchery in a few days.

Cobb cares about the well-being, health and quality of our chicks. After 21 days of incubation, chicks are separated from the eggshells by hand and are then counted into clean chick boxes. Depending on the genetic line and the requests from the customer, female chicks and male chicks will receive additional vaccinations and services in the hatchery that will have a positive benefit for their short-term and long-term welfare outcome. As part of our Cobb Cares philosophy, hatchery employees carefully handle and individually evaluate chicks for welfare and quality traits. We want to be sure that the chicks that we send to the farm have the best opportunity to survive and thrive. This evaluation includes verification of chick weight, physical traits including feather coverage and leg structure, beak shape, navel closure, and accuracy of hatchery vaccinations and services. During the entire process, the hatchery environment is carefully managed so that the lighting, temperature, and ventilation are all suited for the needs of the day-old chicks. After final quality checks, the chicks are placed in specially designed chick boxes for their journey to the customer’s farm.

Transportation

Cobb chicks are carefully delivered to their final destination in specially designed trucks that have fully automated environmental controls. After loading the chick boxes into the truck at the hatchery, the Cobb chick truck drivers ensure that the filtered air, heating, cooling and lighting are all carefully programed so that chicks are comfortable and can rest on the way to the customer’s farm. As part of our Cobb Cares strategy, the hatchery and chick drivers have all paperwork and box counts ready before the truck departs so that there are no delays in transportation or unloading at the time of delivery.

Some Cobb breeder chicks are sent to customers in other countries. Just like our national deliveries, chicks are carefully placed in secure boxes for their international journey. Cobb chick truck drivers load the chick boxes at the hatchery and deliver the chicks to the airport for their international flight. As part of our Cobb Cares dedication, we have teamed up with airlines to train their personnel on chick care and live-animal handling so that the chicks will be as comfortable as possible during their international journey. We also include temperature recording devices with each shipment so that we can verify the chick care and comfort from the time of departure at the hatchery to the time of arrival at the farm.