AirStreamer™ concept

Airstreamer™ hatchers

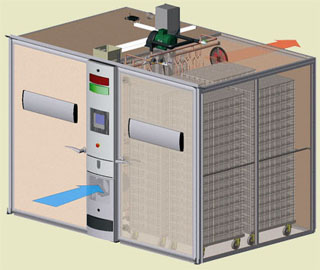

AirStreamer™ hatchers are developed with optimum hatching and hygiene performance in mind as well as unconditional ease of cleaning.

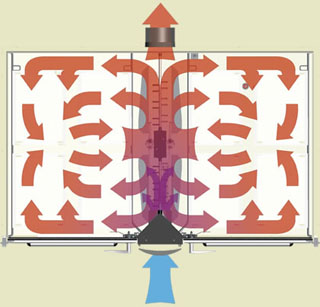

The AirStreamer™ hatcher concept was designed for optimal temperature distribution without compromising cleanability and hygiene; so leading to a simple and straightforward design with various benefits for the user:

-

1. No recycling of air within the hatcher cabinet so as to avoid recycling chick fluff

2. Direct connection between hatcher cabinet and dust corridor (rear exhaust); no ducting required

3. Redesigned (vertical) cooling coils for easy removal of fluff residue after hatching

4. Maximum use of anodised aluminium and stainless steel for extreme durability and corrosion resistance

5. Electrical/electronic parts housed in a water-tight, high pressure cleanable front console

6. Negative pressure inside the hatcher cabinet avoids the exchange of spent air between different machines in the same hatcher room

During the hatching stage of the incubation process, CO2NTROL™ manages CO2 levels to maximise hatching synchrony and performance.