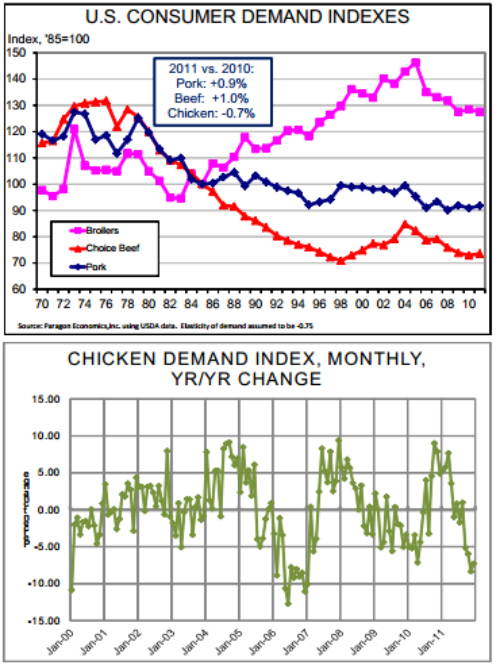

CME: Pork & Beef Demand up, Chicken Down in 2011

US - The release on Monday of USDA's estimates of carcass/ ready-to-cook weight data for December exports provided the last piece of information needed to compute demand indexes for December and all of 2011, write Steve Meyer and Len Steiner. The top chart shows the indexes

since 1970 for the three largest animal protein species. Pork and beef

demand were up slightly (0.9% and 1%, respectively) in 2011 from

their levels of 2010. Chicken demand ended the year down 0.7%, the

fifth time in the past six years that the chicken demand index has declined since peaking at 146.2 in 2005.

Remember that demand is not merely consumption.

These

indexes use per capita domestic consumption and average real retail

prices to compute an index relative to the base period, 1985, that represents the position of a downward sloping demand curve in the traditional Q-P space of a supply-demand diagram. A positive index

change means the demand curve has moved up and to the right in

that space. A negative change is just the opposite. The index value

for a given year represents the position of the demand curve during

that year relative to its position in 1985, the base year.

Indexes for all three species ended 2010 on a roll as the

economy recovered and spending at both grocery stores and restaurants rebounded from the depressed levels of 2008 and 2009. That

momentum continued into 2011 for both chicken and pork but slowed

some in the first half of the year for beef. An improving economy in

late 2011 appears to have positively impacted beef demand with the

last five months (and seven of the last nine months) seeing year-onyear increases in the monthly indexes.

Pork demand, though, struggled from August through November with monthly index figures as much as 5% below those of

2010. That all ended in December when the year-on-year comparison

flipped to a positive 5%.

As can be seen above, chicken demand is still struggling

mightily with all year-on-year comparisons since September 5% or

more below the 2010 level. Reductions in per capita product offerings

have been accompanied by LOWER, not higher, retail prices. Some

of this may be due to the prevalence of long-term pricing agreements

in the broiler sector and the time lags they cause for price responses.

But it would be good to see some response - soon - to lower supplies.

Following up on our discussion of sow gestation stalls

in yesterday's DLR there is one other system that is gaining in

popularity in the U.S. 'Free-access' systems are a hybrid of stalled

housing and group housing that give sows a choice of staying in a

stall or moving around a group area. The stalls are equipped with

gates that close behind sows when they enter and open whenever

they want to leave. The closed gate protects the sow in the stall from

being bothered by other sows. All feeding occurs in the stalls. Water

is available in the stalls as well, allowing them to be locked shut to

allow managers to observe sows, treat sick or injured sows, remove

individuals who may need attention or even confine individual animals

for short periods of time. The stalls themselves are roughly the same

size, 2 feet by 7 feet, as fixed stalls but they do require more space

since there is usually an 8-10 foot alley behind two rows of stalls.

Assuming an 8-foot alley, this system would require 2 feet by 11 feet

per sow or over 50% more floor space. Interestingly, sows spend

most of their time in the stalls since they are protected there and can

lay without being bothered. Virtually all sows do leave the stalls from

time to time.

This system, like the others, has trade-offs. Gaining the

mobility of group housing and the benefits of that mobility (muscle

tone, joint flexibility, presumably less foot lesions, 'happy' sows, etc.)

requires more floor space and equipment with a good number of moving parts. Mixing moving parts and 400-600 pounds sows is almost

always a maintenance nightmare unless the equipment is very well

built. This system would have the potential, like strictly group-housed

systems, of more fighting and consequent injuries but providing the

safety of a stall would mitigate the number and severity of those injuries. Producers who we know to have installed these systems are

generally very satisfied with them even though they are more costly.