APL: Tight Packaging for Poultry

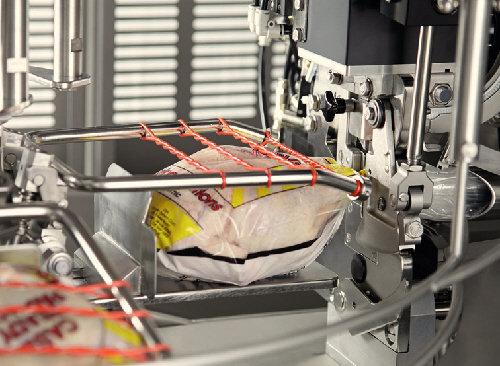

GERMANY - Poly-clip System has equipped its automatic packaging machine for poultry in a bag, the APL, with highly efficient, new functions.The APL loading system packages up to 18 birds (chicken) per minute in PE or stretch bags with reduced handling and use of personnel up to a maximum weight of 2kg per item. The following automated process controls are new.

The new APL makes it easy for the operator. The poultry products are fed in manually while the rest of the production process is fully automatic, and runs with the highest efficiency: bagging, hocking, stretching, air evacuating, labelling and clipping.

Even in terms of ergonomics, the newest knowledge has been implemented in the system operation. Depending on the product fed in, up to 18 bags per minute can be securely clipped.

During the production process, there is an automatic check that the chicken is in the bag before a clip seals it.

The length of the chicken legs will also be checked. If they are too long, then the bag will not be clipped but rather sorted out for manual clipping and the poultry can still be sold. This production step prevents rejects, and contributes to the efficiency of the packaging machine.

Wickets of bags with a minimum thickness of 35μm are used. With the APL, either the aluminium clips or optional plastic clips on spools are used. The high-quality clips are certified according to ISO 22000, in accordance with the HACCP-requirements.

As a matter of course, the APL offers several equipment possibilities as well as stainless steel and an hygienic design.

Poly-clip System is the worldwide leading supplier of clip system solutions.

Tel. +49 6190 8886-341 - www.polyclip.com - [email protected].