Chick Quality Sustaining After Hatch

GLOBAL - This presentation explains that today’s hatcheries must not look at hatch only. Although companies seem to make hatch a priority, we all must remember that integrated as well as independent companies are in the meat business.There are many things we can do or not do to improve field performance. These require a properly set up and a well-maintained hatchery as well as proper equipment for ventilation and incubation. Just as important is the proper implementation of effective programs.

Once the chicks are transferred from the setter to the hatcher, it is important that we implement a step-down temperature profile. Remember, eggs enter the hatcher as embryos and come out as baby chicks. What is often assumed is that all processes after hatch through delivery are correct. During this time period there is typically limited to no monitoring.

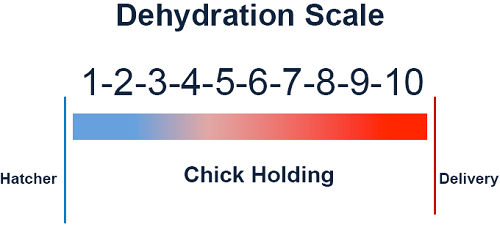

Vital to performance is that the baby chicks do not get hot. Once the chicks have hatched, chick holding begins and continues until delivery. Therefore, there are several areas that we include in chick holding. These are the hatcher, the pull/separator room, chick processing/holding and transportation.

Temperatures need to be monitored at regular intervals in all of these areas. Our target temperature, from hatcher to delivery, is

103.5 - 104.50F.

It is also important that hatchery management considers timing from chick pull to delivery. An example is, if we are 1 hour from pull to delivery we do not want to pull our chicks early (green).

They need to be dry before loading onto transport. See the chart. Some complexes average 30 minutes from hatchery to delivery while others average as long as 10 hours. Our purpose is to deliver a chick in good shape and ready to eat and drink upon arriving on the farm. Overheated and dehydrated chicks become lethargic and will not move to feed or water resulting in poor broiler performance. This problem can occur anytime from the hatcher to delivery. This will affect uniformity, target weights at seven days, etc. Baby chicks need to be pulled at the proper time, processed and delivered to the farm as soon as possible. Do not hold chicks in the hatchery.

Mortality patterns can tell us a lot about how the chicks were managed from hatch to delivery. They indicate what we need to look at. The first three days of the baby chicks’ lives on the farm are the most critical.

The bottom line is that a hatchery needs to be well managed and properly maintained at all times. In doing so management can maximize not only hatch efficiency but also and most importantly good field performance. Hatcheries have a vital role in any company’s profits.

Scott Martin