Egg defects

In this book, individual egg defects are discussed in two groups: shell defects and internal defects. Shell defects are discussed first, as they are the most common cause of downgrading. Individual defects are discussed in general order of decreasing frequency of occurrence within each group. Each defect is described and illustrated, and its expected incidence at the point of grading is given for comparison where appropriate. (The given incidence is for eggs produced under conditions of good management.) Possible causes of an excessive incidence of each defect and the corresponding control measures are outlined.

To put an egg-quality problem occurring on a farm into the correct perspective, it is important to go through the following steps.

1. Quantify the extent of the farm problem Accurately determine the incidence or extent of the problem. Count all eggs with the problem, both at collection and at grading.

2. Determine flock age Flock age has a major impact on the incidence of both external and internal egg defects and so must be taken into account when assessing the severity of a problem. If the birds on the farm vary in age, calculate the weighted average age of the flock, as shown in table 2.

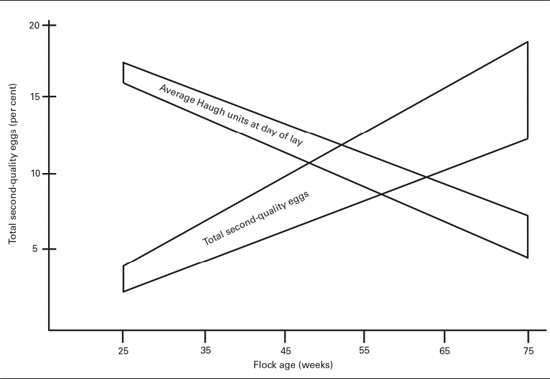

The graph in figure 3 shows the relationship between flock age and both the incidence of second-quality eggs and internal egg quality (measured in Haugh units).

An increased incidence of defects may be primarily the result of an increase in the average age of the laying flock.

3. Assess grading efficiency If too many poor-quality eggs are being packed for sale, the problem may lie in the grading-candling operation or subsequent rough handling. Factors that affect the efficiency of the grading-candling operation include:

Candling speed. As the time that the candling operator has to view each egg decreases (for example, from 0.6 seconds per egg to 0.2 seconds per egg), candling efficiency declines.

Proportion of second-quality eggs. As the percentage of second-quality eggs entering the candling booth increases (for example, beyond 8 to 10%), candling efficiency declines. Removing obviously poor-quality eggs before grading will help reduce the workload of candling operators.

Candling light. Although the intensity of light in itself is not critical, leakage of light around the eggs may reduce efficiency.

Candling mirror. Backing mirrors that are not adjusted to the eye-height of the candling operator will decrease candling efficiency.

Operator. The experience and capability of the operator is a major factor affecting efficiency. Operators should be able to stop the line when overloaded, and should not work at candling too long without a break.

Table 2: Sample calculation of weighted average age of flock

| Flock number | Number of birds in lay in each flock | Age of each flock (weeks) | Total number of birds in lay in all flocks | ||||

|---|---|---|---|---|---|---|---|

| 1 | 1000 | x | 25 | ÷ | 5050 | = | 4.9 + |

| 2 | 1200 | x | 32 | ÷ | 5050 | = | 7.6 + |

| 3 | 1550 | x | 47 | ÷ | 5050 | = | 14.4 + |

| 4 | 1300 | x | 64 | ÷ | 5050 | = | 16.4 |

| Total | 5050 | Average flock age (weeks) | 43.5 |

Figure 3: The relationship between flock age and the incidence of second-quality eggs, and the Haugh unit measure of internal egg quality.

By systematically following the above three steps, an apparent egg-quality problem can be quantified and put into perspective. If the incidence of a defect is too high, possible causes and solutions can be pinpointed by consulting the section of this book on the defect concerned.

© The State of Queensland, Australia (through its Department of Primary Industries and Fisheries) and DSM Nutritional Products Ltd., 2007. No part of this publication may be reproduced, copied or transmitted save with prior written permission of Director, Intellectual Property Commercialisation Unit, Department of Primary Industries and Fisheries, GPO Box 46 Brisbane, Queensland, Australia 4001, and DSM Nutritional Products Ltd.