Hairline cracks

Description

Hairline cracks, i.e. very fine cracks, usually run lengthwise along the shell. As they are diffi cult to detect, candling efficiency needs to be maximised (see page 24). Their presence in fresh eggs can be revealed by careful squeezing or tapping. The crack becomes more obvious as the egg ages.

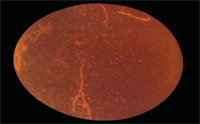

The egg in the photograph has been placed over a bright light. This is the way it would look to a candling operator.

The incidence of this problem varies with flock age, but is usually 1 to 3% of total production.

| Cause | Control |

|---|---|

| Reduced shell strength due to: | |

| Ageing | Keep flock age as low as economically possible. |

| Poor nutrition | Make sure that the birds’ nutrient intake is correct (particularly regarding calcium and vitamin D3) Mixed feed should be handled carefully so that the different components do not separate out. This particularly needs to be checked when augers and automatic feeding systems are used. |

| Saline water | Desalinate, dilute or do not use drinking water containing problem levels of salts. |

| Diseases such as infectious bronchitis | Follow an effective vaccination programme. |

| High shed temperatures | Control temperatures by using foggers, fans, roof sprinklers, white roofs, insulation and good ventilation. |

| Mechanical damage caused by birds’ beaks and toenails | Make sure that: • the cage floor is not too rigid. • the slope of the floor is just enough to allow eggs to roll out. • roll-out trays cushion the eggs as they come to rest against the edge of the tray. |

| Infrequent egg collection | Collect eggs at least twice a day. |

| Rough handling | Do not collect eggs in wire baskets. When stacking fillers of eggs, place one empty fi ller at the bottom of the stack, and a full one directly on top of it. This double bottom layer supports the weight of the stack better. Avoid stacking fillers of eggs more than six high. Pick up and carry stacks with care. Place large eggs on top fillers in a stack. Reduce the severity of impacts during mechanical handling by: • cushioning metal egg guides. • keeping egg roll-out angles between 7 and 8°. • minimising the number of rows of eggs being fed onto cross-conveyor belts at any one time. Educate staff to handle eggs with care during collection and packing. |

COPYRIGHT NOTICE: OPTIMUM EGG QUALITY - A PRACTICAL APPROACH

© The State of Queensland, Australia (through its Department of Primary Industries and Fisheries) and DSM Nutritional Products Ltd., 2007. No part of this publication may be reproduced, copied or transmitted save with prior written permission of Director, Intellectual Property Commercialisation Unit, Department of Primary Industries and Fisheries, GPO Box 46 Brisbane, Queensland, Australia 4001, and DSM Nutritional Products Ltd.

© The State of Queensland, Australia (through its Department of Primary Industries and Fisheries) and DSM Nutritional Products Ltd., 2007. No part of this publication may be reproduced, copied or transmitted save with prior written permission of Director, Intellectual Property Commercialisation Unit, Department of Primary Industries and Fisheries, GPO Box 46 Brisbane, Queensland, Australia 4001, and DSM Nutritional Products Ltd.